Beer Making Equipment

Find innovative production technology for making beer and connect directly with world-leading specialists

As simple as its own ingredients, the grain-hops-yeast trifecta along with water are the big four ingredients for making beer. The beer-making process is known as brewing and involves several steps like milling, mashing, lautering, boiling, and fermentation.

technology picks for beer production

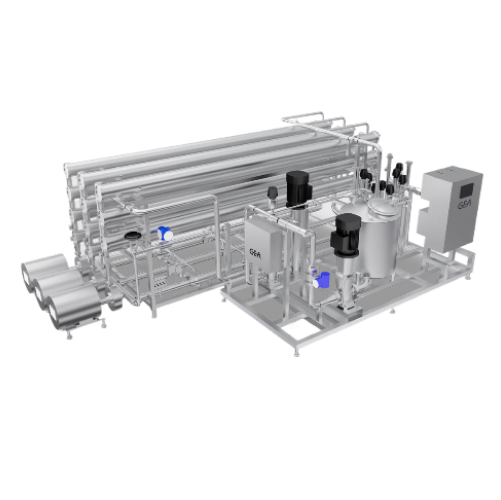

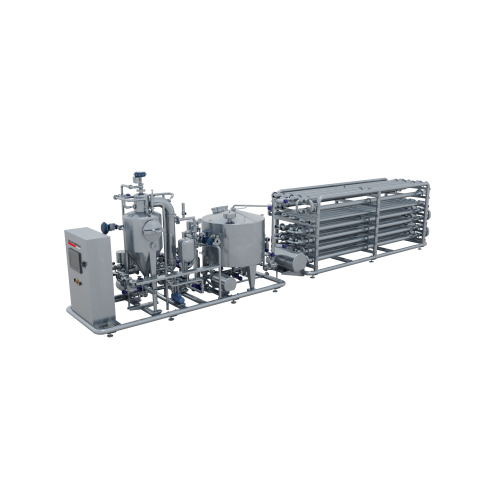

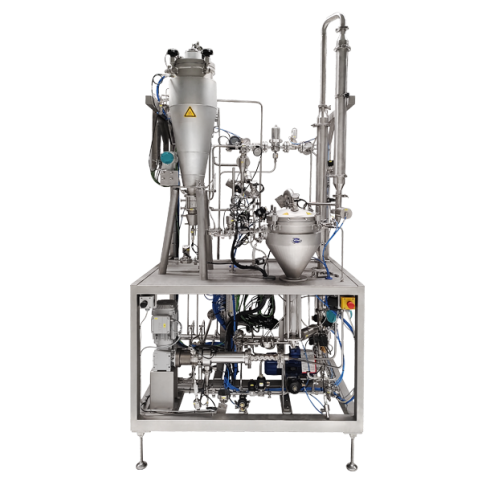

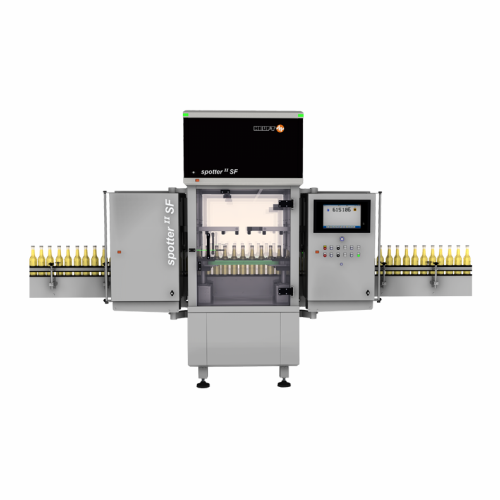

Beer clarification system for brewpubs and small breweries

Optimize your brewing process by minimizing product loss and ...

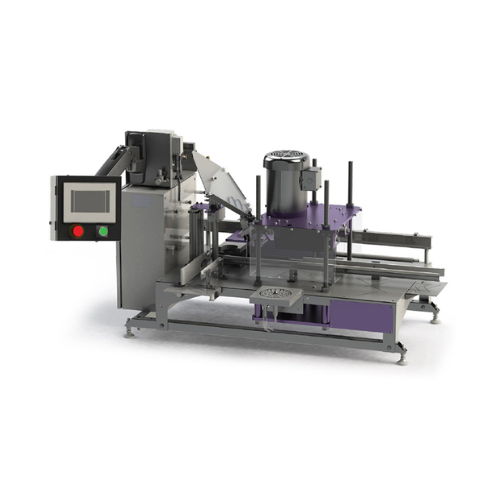

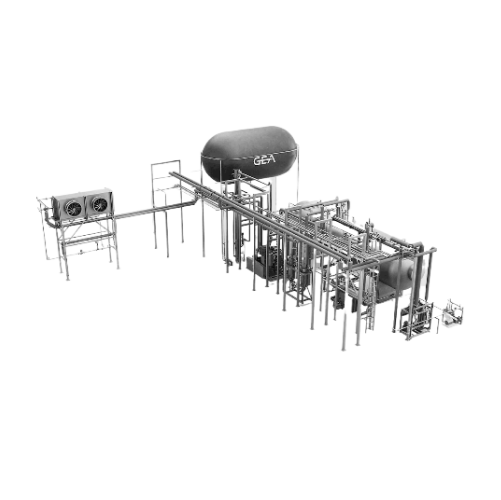

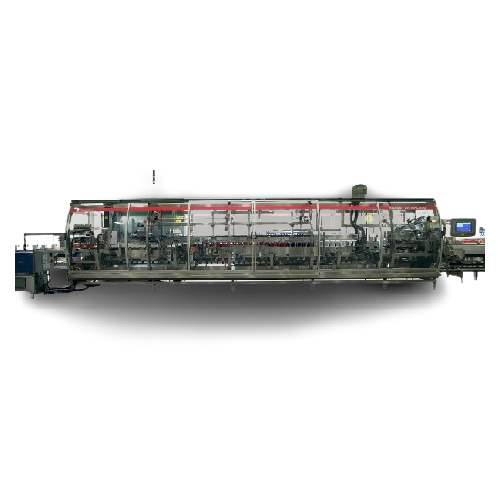

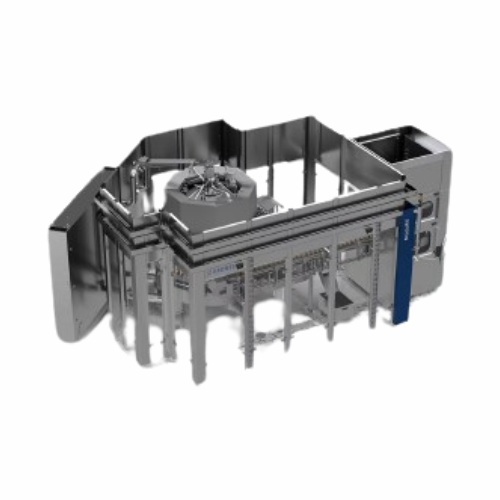

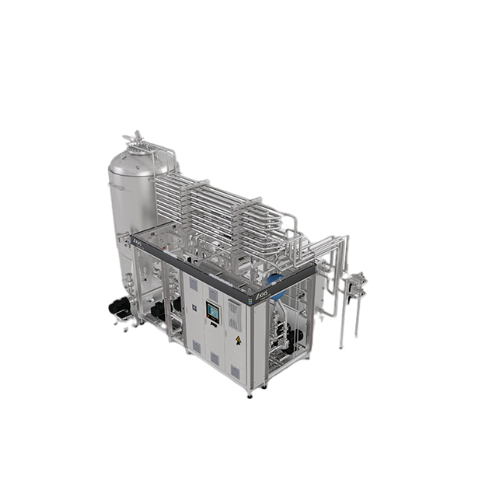

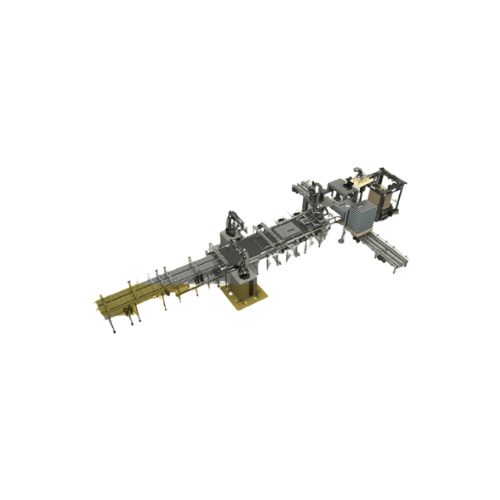

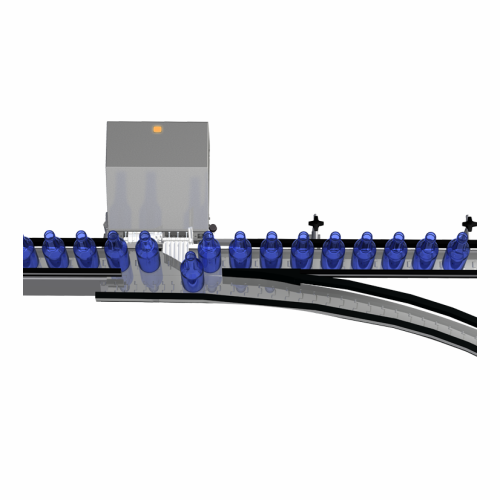

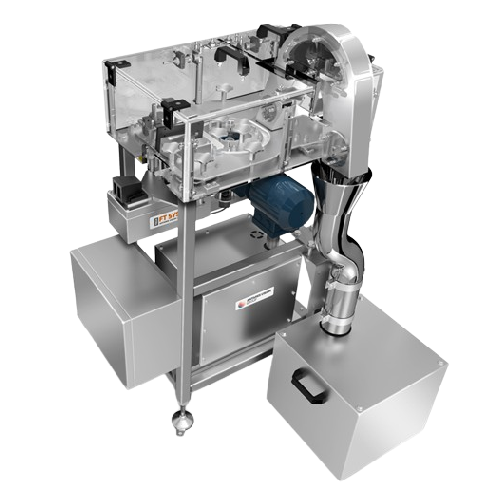

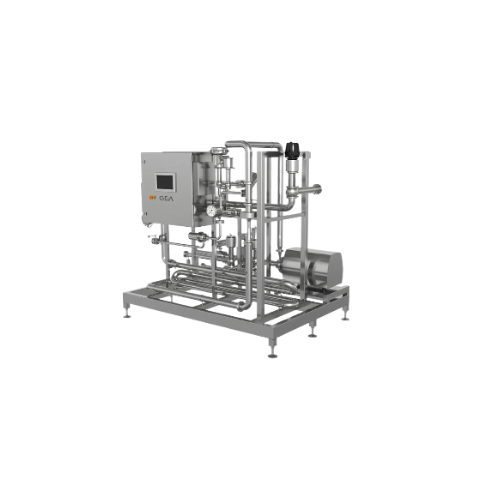

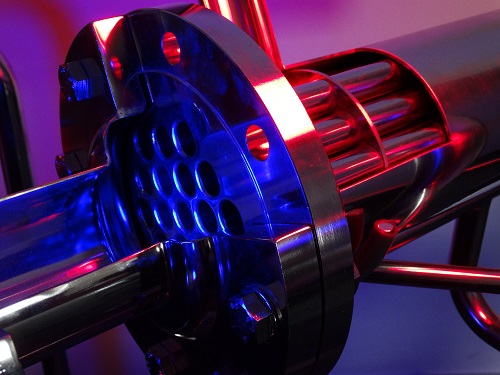

Automated dry hopping system for large-scale beer production

Achieve seamless dry hopping with reduced oxygen pick-up, o...

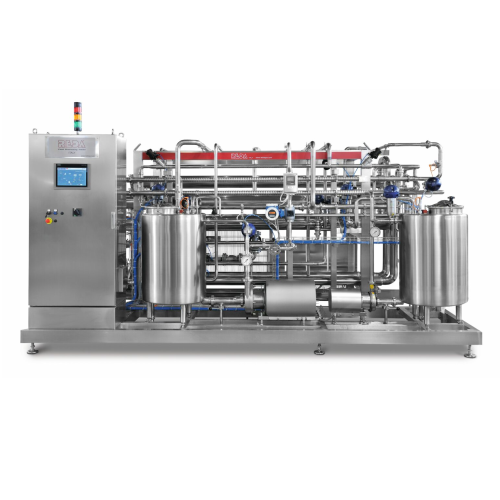

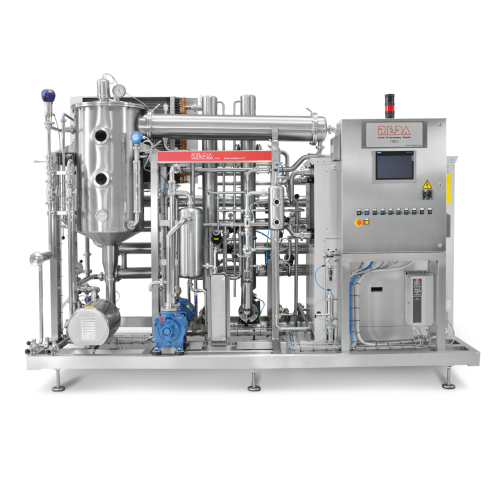

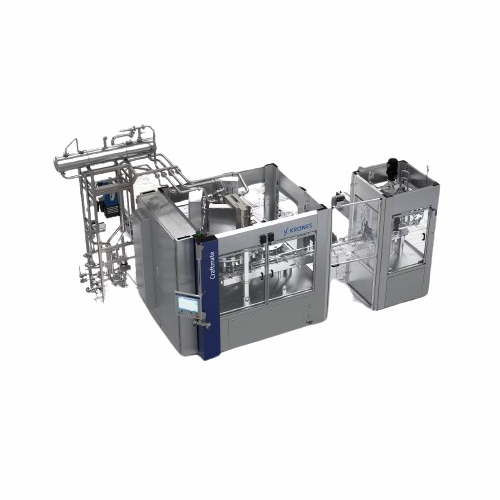

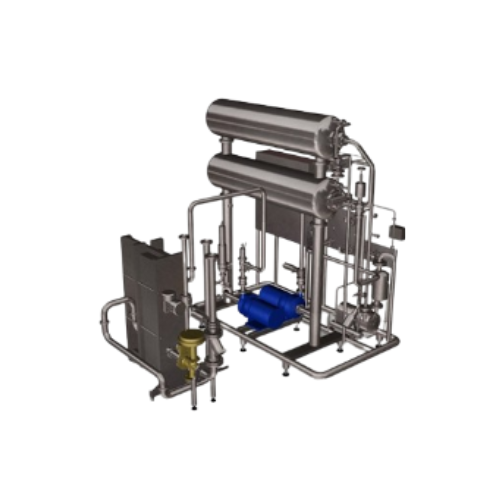

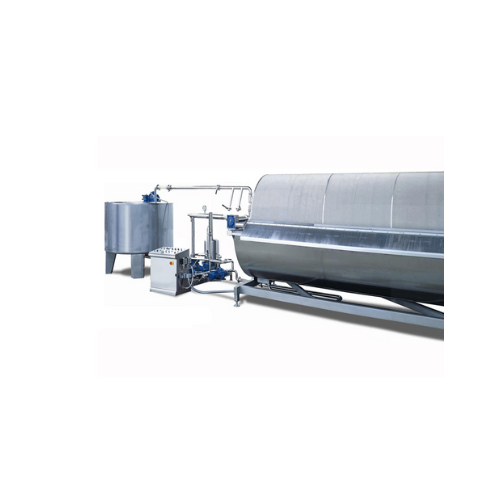

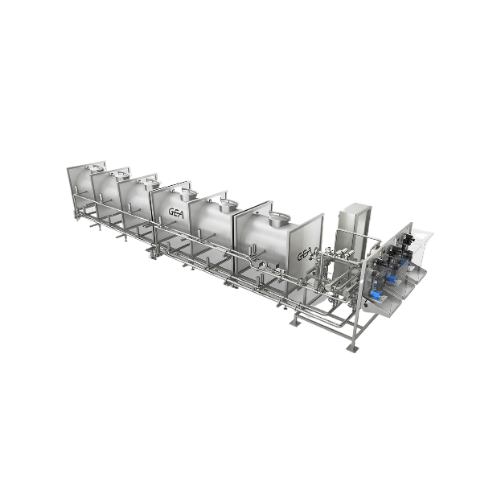

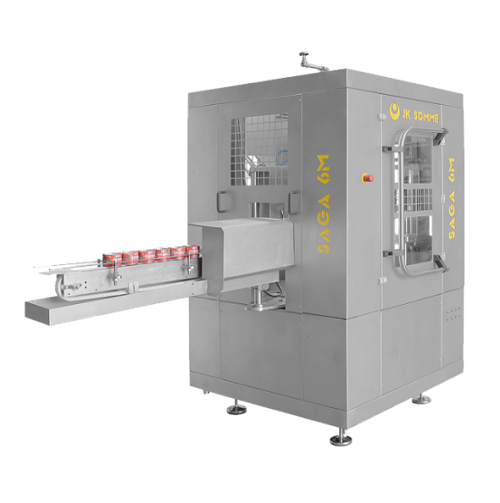

Beer pasteurizer

Contamination and cross-infection by microorganisms is a major risk in the production of foods and beverages....

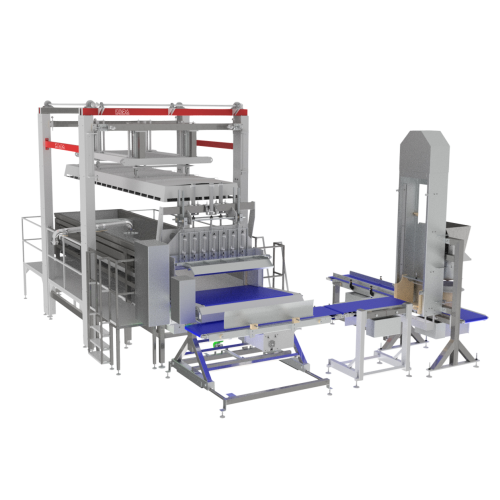

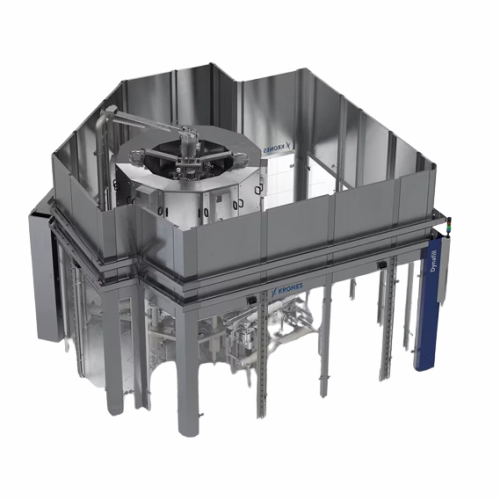

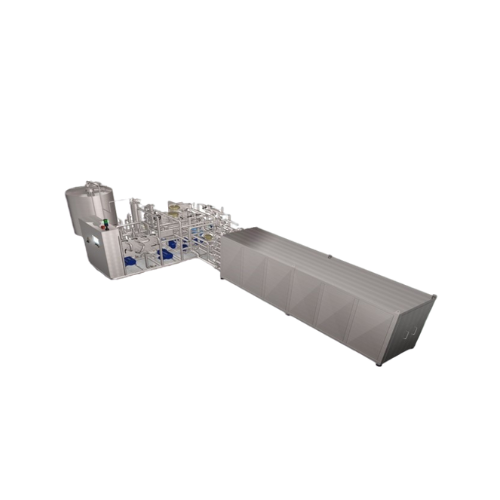

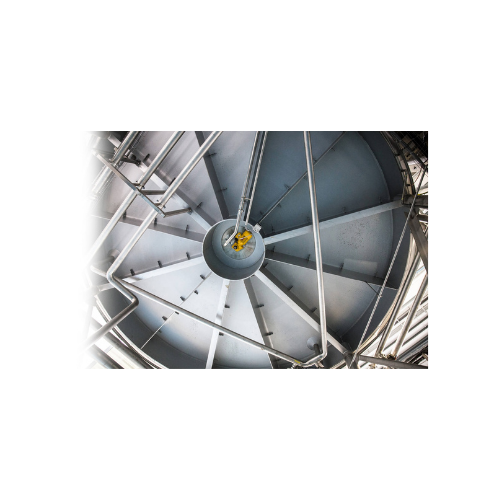

Advanced lauter tun for brewing efficient wort

Optimize your brewing process with a cutting-edge lauter tun that enhances ...

Stories about beer

#Changemaker: dive into circular water management

Crafting Your Beer Story With Packaging

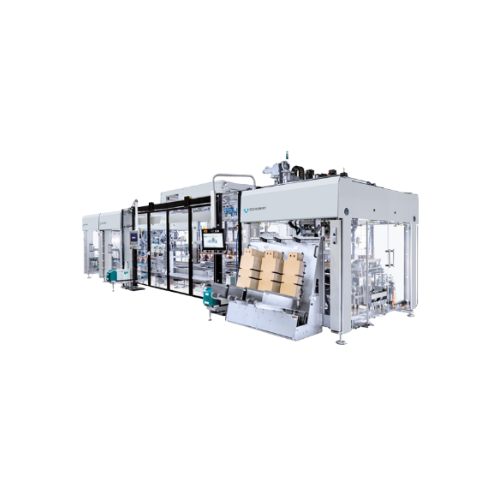

Craft brewers come to the market with a story to tell. Standard packaging, however, no longer fits the bold, fresh personalities of independent beers that resonate with a new generation of drinkers. Advanced case packaging solutions now allow you to make a statement right from the retail shelf with eye-catching casing of different shapes and sizes.

Advantage craft breweries: robots take the frothiness out of cartoning

Select your beer process

Tell us about your production challenge

Ingredients in the beer brewing process - How much do they matter?

Beer is the oldest man-made drink. Just think that its first evidence dates back to 13,000 years ago. It is made up of natural ingredients, water, grains, hops, and yeast through the brewing process. Each ingredient plays a key role. Water quality is very important when you brew because its mineral content can affect the flavor you get. The color of the beer depends on how long you toast or roast your grain. When toasting grain, beer has a caramel color, but if you roast it longer than usual, you will get a darker beer. Hops are important for providing bitterness and flavor; the yeast is to convert sugar into ethanol, which makes beer the alcoholic drink we all know and love. But which production steps and brewing equipment are needed to make beer? The recipe is a crucial component that should be followed to achieve the desired result.

Beer-making equipment – Which brewing systems do you need?

Purifying water to remove chlorine and sulfur is the first step in brewing beer. Sanitation is key to ensure that all equipment used in this process is clean and free of any harmful bacteria or contaminants. By mixing water and grain you get a sugar liquid that brewers call wort. To create it, hot water is added to the grain to convert the grain starch into sugars in a vessel called the mash tun. The wort is moved to a brew kettle where it is brought to boil. Here, hops are added to balance the sweetness of the sugar liquid with some bitterness. They also give aroma and flavor to the beer.

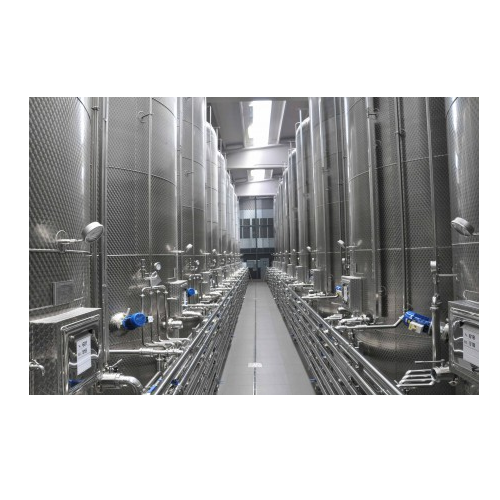

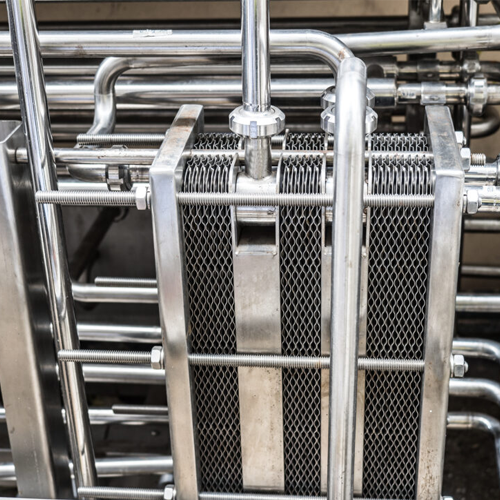

After boiling, the wort is pumped through a wort chiller or heat exchanger to rapidly cool it to fermentation temperatures. In the stainless steel fermentation vessel, which can be a horizontal tank or a conical fermenter, the yeast converts glucose into ethanol while releasing CO2. Batch brewing is a process that allows for greater control over the quality and consistency of the final product. When the first stage of fermentation ends, yeast is added again to remove any remaining sugar (secondary fermentation). Before filling, beers are filtered through a centrifuge to remove any remaining substances. The final product is then dispensed into kegs for commercial distribution.

From homebrew equipment to industrial scale

Compared to industrial breweries and brewhouses that produce a large amount of beer annually, a microbrewery, also known as a craft brewery is a small, independent brewery that produces 15,000 beer barrels or less per year. To turn your passion for beer into your business, the first thing to look for is home brewing equipment. You will need a mashing system to mix hot water and grain so that the starch starts to convert to sugar (wort). If there is no sugar, there will be no alcohol. Next, you will need a lautering system and a brew kettle to boil the wort with the hops; a heat exchanger to cool the wort for fermentation, and last but not least a fermentation vessel or carboy where the yeast will convert the sugar to ethyl alcohol. Aside from production capacity, what sets microbrewery apart is the freedom to experiment with new flavors and production techniques.

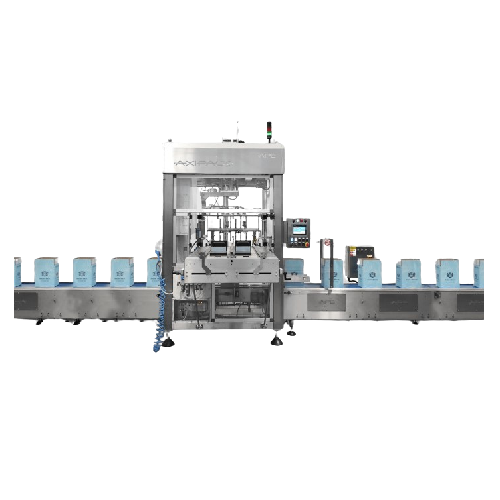

Case packaging for carrying your branded beer packs

Case packaging can influence the choice of beer lovers. For this reason, great breakthroughs have been made in terms of packaging design. You can choose the colors, shapes, and sizes of your packaging according to your needs. The case packaging process usually takes place in a wraparound machine that loads a carton that wraps and shapes around the products to form a box. For easy transport, cartons usually are made with handles.

Processing steps involved in beer making

Which beer technology do you need?

Kieselguhr-free beer clarification system

Achieve high-clarity beer without kieselguhr using a sustainable system combinin...

Flash pasteurizer for beer and carbonated beverages

Ensure optimal flavor and safety in your beverages by integrating a c...

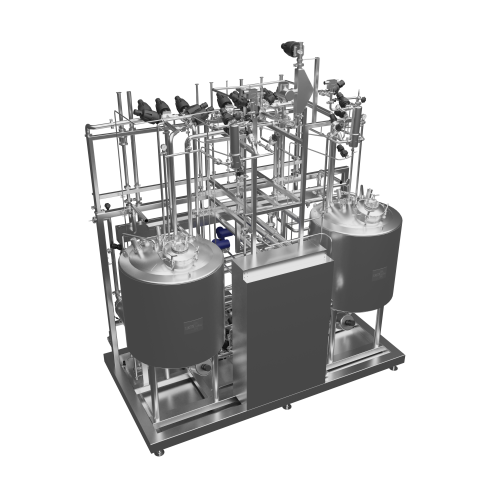

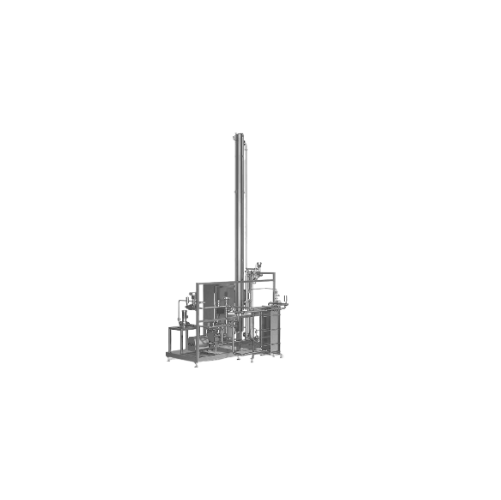

Yeast propagation system for breweries

Achieve optimal yeast propagation with this advanced system, ensuring consistent bee...

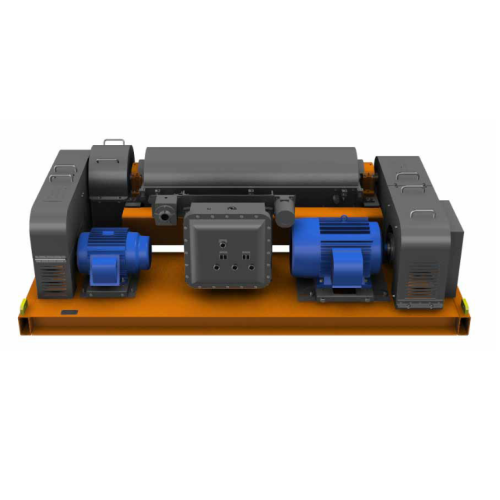

Dry hopping skid for breweries

Optimize your brewing process with this advanced technology, reducing hop aroma losses and im...

Small batch craft brewhouse

Maximize brew quality and efficiency with a brewing system designed for experimentation and prec...

Skid-mounted yeast propagation system for craft breweries

Enhance your brewing capabilities with a versatile propagation...

Beer clarification system for brewpubs and small breweries

Optimize your brewing process by minimizing product loss and ...

Craft brewhouse for medium to large breweries

Achieve unparalleled brewing flexibility and efficiency with a brewhouse tha...

Wort aeration system for craft breweries

Optimize your fermentation process with precise aeration control, ensuring optimal...

Separators for biochemicals

Achieve precise separation and purification of complex biochemical mixtures with self-cleaning c...

Clarifier for beverages

Enhance beverage clarity and purity with high-performance centrifugal separation, expertly designed t...

Advanced lauter tun for brewing efficient wort

Optimize your brewing process with a cutting-edge lauter tun that enhances ...

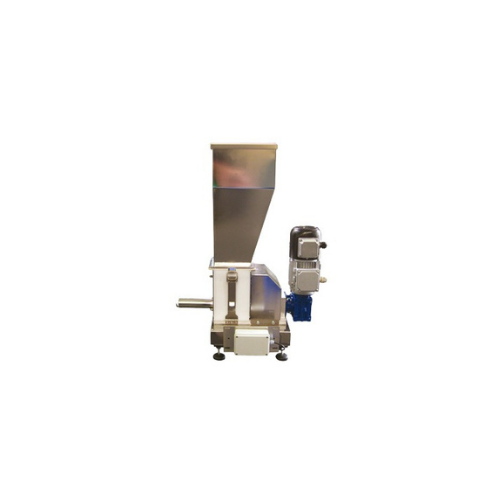

Milling system for breweries

Enhance your brewing process with a system that conserves grain husks while optimizing endosper...

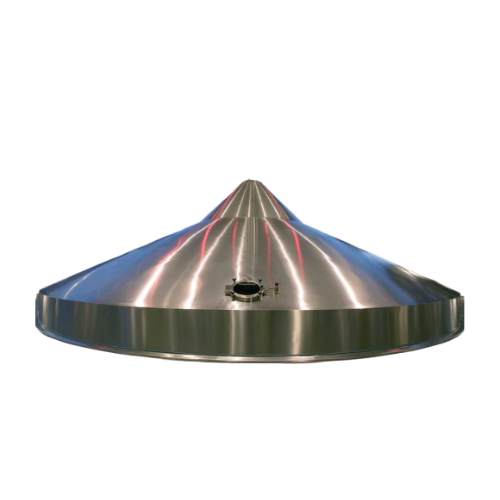

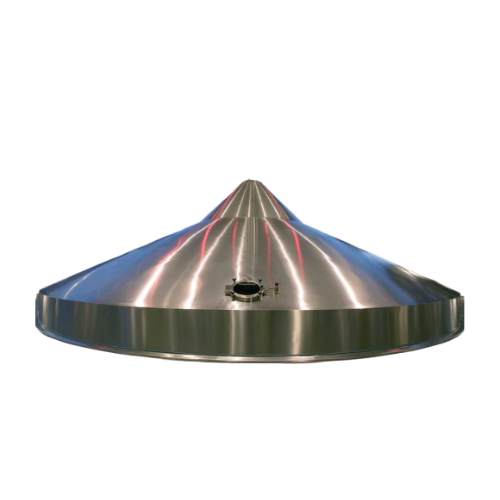

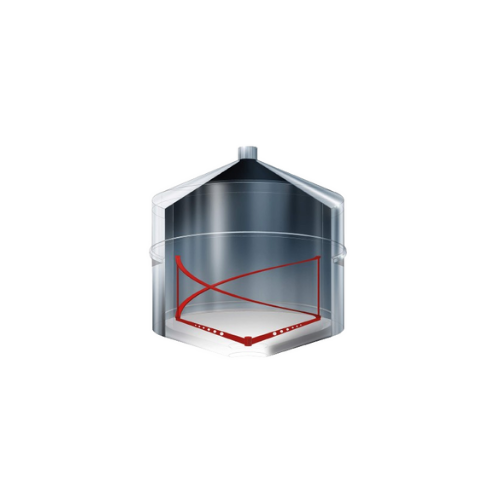

Whirlpool vessel for hot trub separation in brewing

Achieve efficient hot break separation in your brewery with whirlpool...

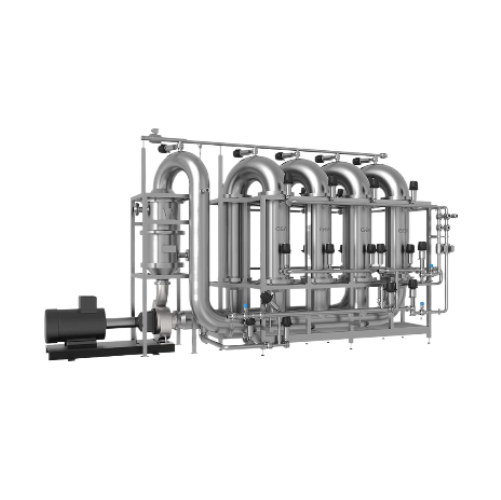

Energy efficient wort boiling system

Optimize your brewing process with a two-phase wort boiling system that reduces energy...

Wort cooler for brewery wort treatment

Efficiently transition your brewing process from hot to cold phases with precise tem...

Wort aeration system for optimal fermentation

Ensure consistent beer quality and efficient fermentation initiation by util...

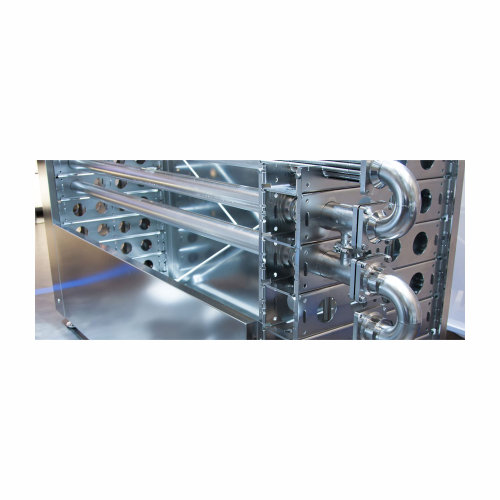

Cold block piping solution for breweries

Achieve optimal beverage quality and reduce production costs with this advanced pi...

Piping solutions for breweries cold block area

Efficiently distribute and regulate media within your brewing process, ensu...

Ceramic membrane-based beer filtration

Achieve crystal-clear beer without waste using innovative ceramic cross-flow membran...

Carbonation system for beer and beer mix beverages

Achieve precise carbonation in beer and mixed beverages with a system ...

Membrane filtration unit for hard seltzer production

Effortlessly produce a clear, aroma-free base for hard seltzers by e...

Membrane dealcoholization unit for beer

Enhance your brewery’s capabilities by efficiently removing alcohol while pre...

Mixing system for beer mix beverages

Enhance your beverage offerings with precise mixing and dosing systems designed to pro...

Co2 recovery system for breweries

Unlock the full potential of fermentation by capturing and purifying CO2 for immediate re...

Uht sterilization for drinkable milk

Ensure long shelf-life and food safety without compromising the natural qualities of y...

Pasteurizer for extended shelf-life (esl) milk

Extend the shelf life of milk while maintaining its taste and nutritional i...

Wine clarification system

Enhance your wine production by effectively removing unwanted solids and reducing oxidation risk, ...

Whey processing line

Streamline whey processing by transforming byproducts into high-value proteins, catering to diverse nutr...

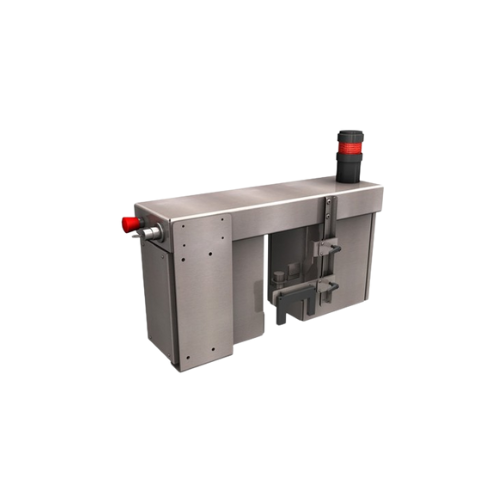

Milk collection system for bulk tankers

Optimize milk transfer and storage with a reliable system that reduces discharge ti...

Milk skimming separators for dairy applications

Enhance dairy production with high-efficiency skimming separators that opt...

Milk standardization system

Achieve precise milk and cream fat standardization with this advanced inline system, optimizing ...

Pasteurizer for fresh milk

Ensure your dairy and beverage lines achieve optimal product safety and quality by leveraging adv...

Grape must concentration solution

Optimize the alcohol content and flavor profile of your wines by efficiently concentratin...

Membrane filtration for whey concentration

Enhance your liquid processing with advanced membrane filtration designed to im...

Blending and mixing unit for dairy and beverages

Achieve precise recipe control and high-quality results by seamlessly int...

Cheese forming units for hard and semi-hard cheeses

Optimize your cheese production process with advanced moulding and pr...

Low temperature evaporator for heat-sensitive food products

Efficiently concentrate sensitive liquid products while pres...

Wine dealcoholization system for low-alcohol wines

Struggling to meet market demands for low-alcohol wines? Achieve preci...

Milk evaporator for dairy industry

Optimize your liquid food production with precise control over evaporation processes, en...

Vacuum deaeration with aroma recovery for juices

Eliminate oxygen from liquid foods to prevent oxidation while retaining v...

Fermentation tank for yoghurt and fermented dairy products

Optimize your dairy and plant-based drink production with eff...

Bacteria removal separator for dairy products

Ensure top-quality dairy and plant-based products with reliable bacteria rem...

Brine purification system for reducing bacteria and molds

Ensure pristine brine quality by continuously removing bacteri...

Clarifier for milk and whey

Optimize dairy and beverage production by efficiently removing fine curd residuals, ensuring hig...

Juice clarification system

Ensure consistent beverage clarity with advanced separation technologies, enhancing production ef...

Curd making equipment for cheese production

Optimize your cheese production with versatile curd making equipment, designed...

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

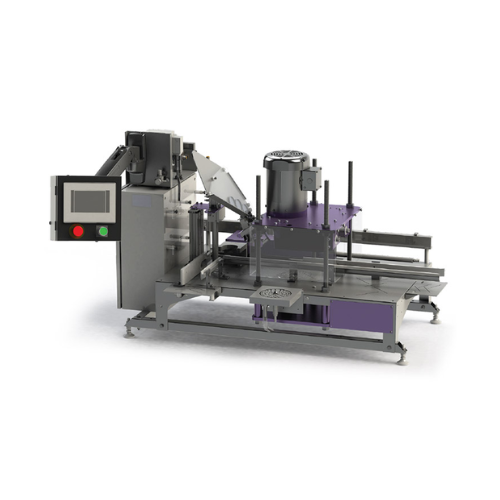

Beverage multi-pack cartoner for cans and bottles

Optimize your beverage production line with high-speed, continuous mult...

Pasteurization solutions for liquids with solid pieces

Ensure the integrity of fruit inclusions in beverages and dairy wi...

Centrifugal pumps for food & beverage and biopharmaceutical applications

Optimize your liquid transfer processes with p...

Aseptic sampling devices for biopharmaceutical applications

Secure aseptic sampling ensures your high-value biopharmaceu...

Mobile cleaning-in-place unit for process equipment

Ensure seamless cleaning of diverse process equipment with a mobile, ...

Compact cleaning in place units for food industry

Optimize your production line with a compact system designed for effici...

Cleaning-in-place for multiple equipment in food industry

Ensure precise hygiene and traceability with a system designed...

Cleaning and sterilization in place for hygienic control

Ensure maximum hygiene and sterility in your production line wit...

Stainless steel process vessels for biopharmaceutical applications

Ensure seamless mixing and sterilization with engine...

Ped tested filtration system for sparkling wines

Ensure consistent carbonation and clarity in your sparkling beverages wit...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Laboratory in-line sterilization system

Ensure precise temperature control and rapid cooling for diverse liquid application...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Sterile filling and closing bench for bottles and cups

Ensure precise and sterile filling for liquid products with a hygi...

Aseptic bag-in-box filler for laboratory use

Achieve aseptic filling precision on a lab-scale with a compact solution that...

Lab-scale high-pressure homogenization solution

Optimize your lab-scale production with precision homogenization, ensuring...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

Small-scale in-container spray pasteurizer for laboratory use

Optimize your R&D processes with precise control over...

Manual Cip unit for lab and pilot plant cleaning

Need thorough cleaning without disassembling your pilot plant? This compa...

Batch deaerator for reduced oxidation in liquid processing

Optimize product shelf life and quality by efficiently removi...

Continuous deaeration solution for laboratory and pilot systems

Achieve superior product stability and minimize foaming ...

Counter-pressure filler for carbonated drinks

Enhance your carbonated beverage production with advanced counter-pressure f...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Carbonation and can seaming solution for beverages

Optimize your beverage production with a seamless integration that sim...

Automated case erector for Rsc cartonboard

Streamline your packaging line with an innovative solution that efficiently for...

Automatic case erector for Rsc-american cartonboard

Streamline your packaging process with precise and efficient setup by...

Automatic case erector for cartonboard with hot-melt glue binding

Streamline your packaging line with efficient case er...

Unpacker for return bottles

Effortlessly manage return bottle operations with high-speed unpacking solutions that ensure pre...

Automated carton former for Rsc american boxes

Streamline your packaging line with high-speed carton forming that combines...

Automated carton forming for bottles

Optimize your bottling line with an integrated carton forming solution that combines s...

Beer fermentation tanks

Ensure optimal fermentation climate control for all beer styles with customizable tanks designed for ...

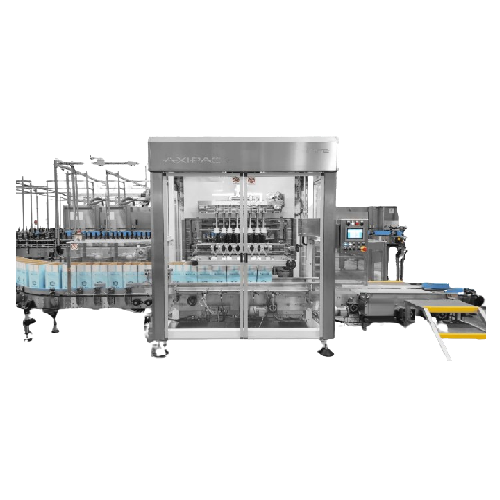

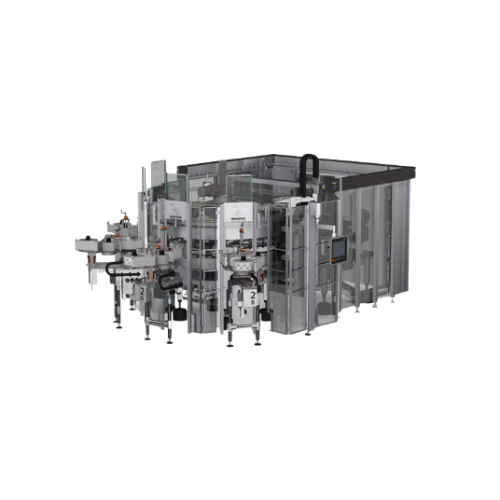

Automated bottle packaging solution for breweries

Streamline your packaging process with a compact unit that combines bas...

Depalletisers for high-capacity bottle handling

Streamline your bottling line with a versatile depalletising system design...

Flexible depalletizers for bottling lines

Streamline your packaging operations with a compact depalletizing solution desig...

Automated case erector for high-speed packaging lines

Streamline your packaging line with this solution that forms and se...

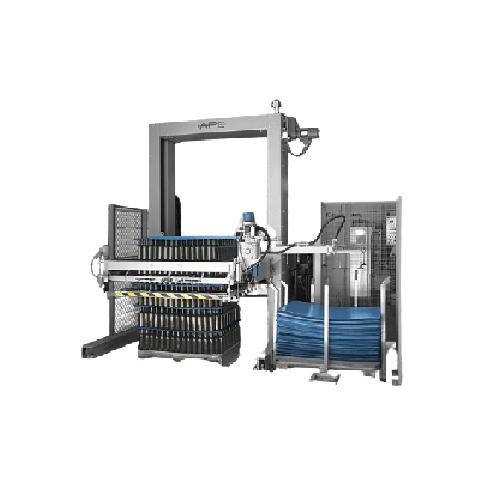

Automatic palletizer for bottle packaging lines

Streamline your bottling line with advanced palletizing solutions engineer...

Bottle repacking system for return cartons

Optimize your bottle repacking efficiency with a system designed specifically f...

Automated packaging line for bottling industry

Streamline your packaging operations with a fully automated solution design...

Automated case erector for american cases

Streamline your packaging line by efficiently erecting American-style cases with...

Automatic bag-in-box packaging system

Optimize your liquid packaging with a precise and seamless workflow, ensuring efficie...

Advanced case erector for Rsc/american cartonboard

Optimize your packaging line with precise case erection and glue seali...

In-line weight filler for drums and kegs

Achieve precise and efficient weight-based filling for large liquid containers, en...

Robotic crating and decrating solution for returnable glass bottles

Streamline your bottling line by efficiently handli...

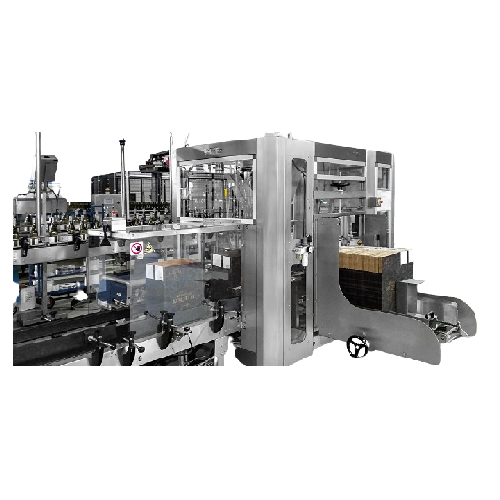

High-speed wrap-around case packer for beverage industry

Optimize your packaging line with a high-speed case packer that ...

Fermenting tanks for beer production

Optimize your beverage production with advanced fermenting tanks designed to enhance t...

Filling and capping solution for bottles

Optimize your bottling efficiency with a robust solution designed to streamline fi...

Continuous inline capping system

Perfect for high-speed operations, this system ensures precise capping of diverse container...

Heavy-duty palletizing robot for production lines

Effortlessly streamline your production with this robust palletizing ro...

Flash pasteuriser for beer

Ensure superior beverage quality with precise pasteurisation and carbonation while minimising ene...

Compact tunnel pasteuriser for beverages

Ensure beverage safety with precise pasteurisation in a compact design that integr...

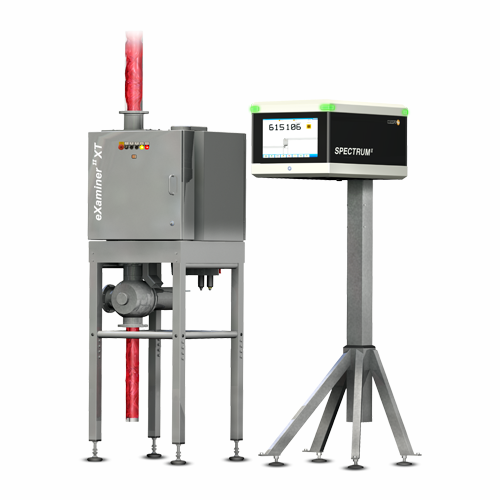

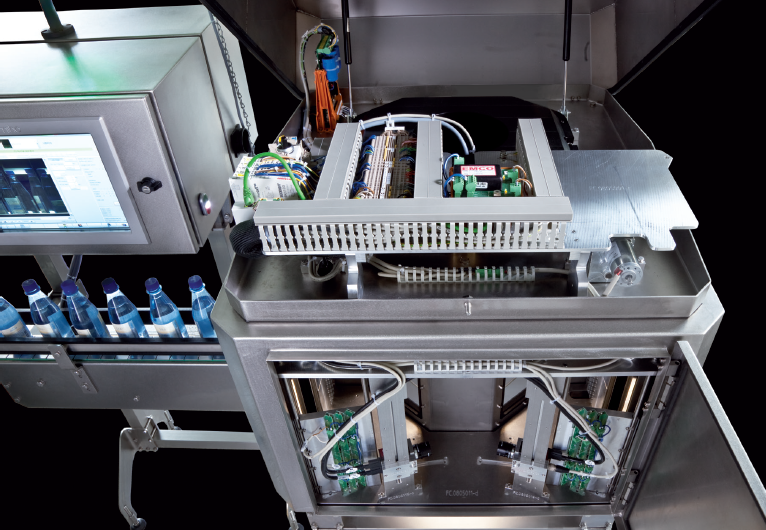

X-ray container inspection system for beverages

Ensure the integrity and quality of your beverage products with cutting-ed...

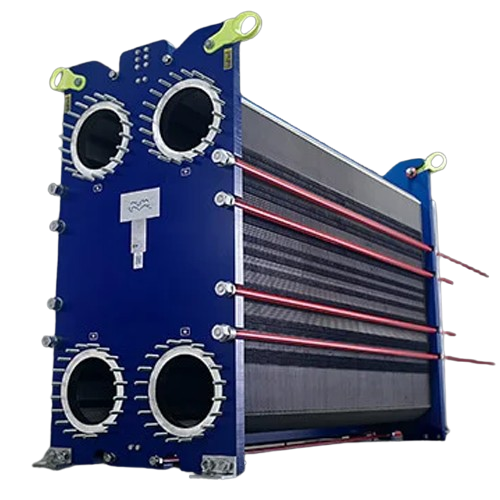

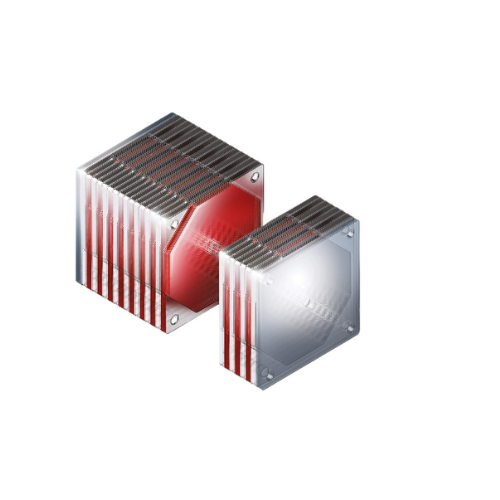

Heat exchanger for beverage production

Ensure your beverages maintain their quality and safety with a versatile heat exchan...

Crate washer for beverage manufacturers

Ensure thorough cleaning of beverage crates with an advanced washing system featuri...

Can inspection unit for quality control

Ensure the integrity of your beverage cans with precise defect detection and qualit...

Caustic residue detection for bottle washing

Ensure product purity by detecting and eliminating residual caustic in return...

Inspection systems for fillers and cappers

Ensure precise fill levels and secure cap placements with advanced inspection s...

Cip system for cleaning bottling lines and processing sections

Ensure a sterile production environment by integrating a ...

Bottle inspection system for foreign particles detection

Ensure your beverage products remain uncontaminated with high-pr...

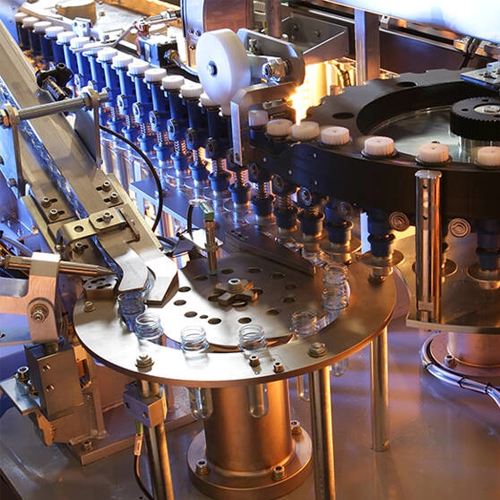

Innovative beer filling and capping technology

Revolutionize your filling process with an integrated system that combines ...

Automated product change-over system

Maximize your production line efficiency by reducing downtime during product changeove...

Blow-moulder and labeller integration for Pet bottles

Streamline and enhance your PET bottle production with seamless blo...

Low output can filler for craft beer

For beverage producers looking to efficiently fill cans with precision, this versatile...

Filler-seamer block for cans

For high-speed beverage production, this solution integrates filling, seaming, and cleaning in ...

Wine and beer clarification system

Achieve superior clarity and stability in your wine and beer production, eliminating sus...

Mbr module for wastewater treatment

Optimize your wastewater management with efficient membrane bioreactors, designed to en...

Flexible labeling system for returnable and non-returnable containers

Achieve precise labeling and enhanced alignment w...

Self-adhesive labeling for glass and Pet bottles and beverage cans

Maximize your production efficiency with a labeling ...

Flexible packaging system for beverage containers

Streamline your packaging process with a modular system that adapts sea...

Enclosed film packaging solution

Eliminate the need for corrugated trays and minimize packaging waste with a robust solution...

Bright beer tank cellar for beer storage

Enhance your beverage production efficiency with a fully automated solution that m...

Water deaerator for beverage production

Enhance the quality and extend the shelf life of your beverages with our cutting-ed...

Filter system for beverage stabilization and clarification

Ensure your beverages are crystal clear and stable with a ver...

Energy-efficient hot filling system for beverages

Optimize your beverage filling processes with a system that ensures pre...

Blending system for fine adjustment of original gravity in beer

Ensure precise control over your beer’s original gravity...

Continuous flash pasteurizer for beverage shelf life extension

Maximize beverage shelf life with precise microbial and e...

Blending system for deaeration and carbonation of beverages

Achieve precise blending, efficient deaeration, and accurate...

Stretch blow molding with integrated coating for Pet bottles

Enhance product longevity and quality by integrating stretc...

Pet bottle stretch blow molding with coating and filling

Extend the shelf life of your beverages and liquid products with...

Transparent glass barrier coating for Pet bottles

Ensure the longevity of sensitive beverages and liquid foods with glass...

Carbonating solution for precise Co2 content in beverages

Enhance your beverage production with seamless CO2 integration...

Compact cleaning system in container format

Optimize your production lines with a space-saving cleaning system capable of ...

Cip cleaning system for food and beverage production lines

Ensure microbiological safety and maintain quality standards ...

Dosing and blending system for beverage production

Enhance your beverage production with a flexible system capable of pre...

Multifunctional filter system for beverages and gases

Achieve precise filtration across multiple beverage and gas mediums...

High-performance palletizer for cans, Pet, and glass containers

Elevate your palletizing efficiency with cutting-edge ro...

High-performance distribution and combining system

Streamline your packaging operations with a versatile system designed ...

Robotic layer grouping system for container distribution

Streamline your packaging line with precise, high-speed containe...

360° palletizing and depalletizing robot

Optimize your packaging flow with a robot offering seamless 360° operation for pre...

180° palletizing robot for automated palletizing and depalletizing

Optimize your production line with a versatile solut...

Flexible tunnel pasteurizer for beverage sterilization

Maximize product safety and flexibility in your production line wi...

Glass bottle filler for beer and soft drinks

Optimize your beverage production with a high-speed filling solution that red...

Pet bottle filler for hot and cold still beverages

Achieve high-speed precision in filling and capping for various bevera...

Modular labeling system for beverage containers

Easily adapt to evolving labeling needs with this flexible system, designe...

Gentle container conveyor for bottles and cans

Achieve seamless container flow with minimal noise and enhanced precision, ...

Multifunctional packing system for beverage containers

Maximize your facility’s packing efficiency with a versatile...

Packer and unpacker for returnable and non-returnable containers

Streamline your packaging line with a versatile machine...

Depalletizer with accurate level compensation

Optimize your high-speed assembly line with a depalletizer designed for prec...

High-speed beverage industry palletizer

Optimize your palletizing process with a flexible, high-speed solution that adapts ...

Closure inspection system for crown corks and metal caps

Ensure product integrity with high-speed 360° closure inspection...

Industrial code verification system for product packaging

Ensure flawless packaging integrity with high-speed code verif...

High-precision fill level checker for beverages and containers

Ensure precise fill levels and prevent product wastage by...

Rejection system for standing bottles and cans

Ensure seamless quality control by precisely rejecting defective bottles an...

Label inspector for beverage and food containers

Ensure precise label application with high-speed inspection, crucial for ...

Container ejection system for Pet bottles and beverage cans

Ensure product quality by seamlessly ejecting defective cont...

Container rejection system for high-speed operations

Ensure product safety by swiftly removing defective containers at hi...

Bottle filler for beer and soft drinks in glass bottles

Achieve precision in bottling with reduced CO2 emissions and low ...

Pvpp beer stabilization system for breweries

Reduce beer hazing and extend shelf life with this advanced stabilization sys...

Crossflow filter for liquid filtration in food industry

Enhance your liquid filtration process with a versatile crossflow...

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

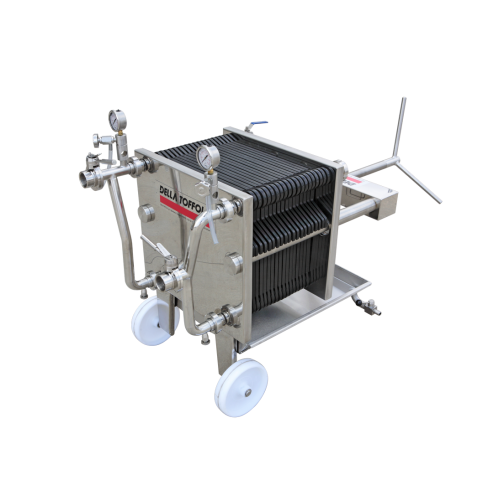

Industrial sheet filter for liquid filtration

Optimize your liquid product purity with precise filtration, maintaining int...

Vacuum rotary filter for liquid filtration

Enhance your production line’s efficiency with precise filtration, ensuri...

Centrifugal separators for dairy products

Enhance your liquid food product quality with centrifugal separators designed fo...

Manual Cip system for food processing hygiene

Designed for small-scale hygiene needs, this mobile clean-in-place system en...

Oxygen and carbon dioxide monitoring and elimination system

Achieve precise control over dissolved gases with a system t...

In-line additive dosing systems for beverages

Ensure precision and safety in beverage production by integrating in-line do...

Piping discharge system for product separation in transfer lines

Optimize your beverage production by preventing product...

Micro-filtration system for beverage industry

Achieve microbiological stability at cold temperatures with our micro-filtra...

Powder mixing system for beverage industry

Enhance your beverage production with an advanced powder mixing system that ens...

Wine recovery system for bottling processes

Streamline bottling operations by recovering and re-dosing valuable wine, redu...

Co2 dosing system for effervescent beverage bottling

For beverage manufacturers requiring precise carbonation, this solut...

Automated system for cleaning in place (cip)

Ensure thorough, efficient cleaning of your production equipment with a syste...

Top loading case packer for loose or bundled bottles

Effortlessly handle and pack both standard and uniquely shaped bottl...

Pipeline inspection for liquid and paste-like products

Ensure your liquid and paste-like products are free from foreign o...

Full container inspection for glass and Pet bottles

Ensure the highest product quality by detecting foreign objects and m...

Closure inspection for beverage containers

Ensure the integrity of your bottled products with precision closure inspection...

Ultrasonic leak detection system for carbonated beverages

Ensure the integrity of your carbonated beverages by precisely...

Semi-modular labeller for precise beverage bottle labelling

Achieve millimeter-precision bottle labelling with seamless ...

X-ray assisted empty bottle inspection

Enhance your production line with advanced X-ray and optical technology to ensure pr...

Fill level and closure inspection system

Ensure precise fill levels and secure closures in high-speed liquid packaging envi...

Advanced foreign object inspection for full beverage containers

Ensure consumer safety and brand protection with advance...

Full case check for beverage production lines

Ensure complete packaging integrity by detecting and removing cases with mis...

Conveyor control system for beverage filling lines

Optimize your production line’s efficiency by seamlessly managin...

Curve rejector for beverage containers

Ensure seamless and upright rejection of faulty containers in tight spaces, maintain...

Empty bottle inspection for beverages

Ensure high quality control and prevent contamination in beverage production lines wi...

Juice storage tank with hygienic and cooling options

Ensure optimal freshness and stability of juices and beverages with ...

Fermentation monitor for alcohol production

Optimize anaerobic yeast fermentations with precise monitoring of carbon conve...

Energy efficient wort boiling system for breweries

Maximize energy efficiency and wort quality with this boiling system t...

Complete bottling lines for beverage industries

Optimize your bottling process with high-speed, precision-engineered lines...

Decanter centrifuge for soft sediment separation

For operations dealing with soft, easy-flowing sediments, ensuring effici...

2-phase separator for clarifying liquids

Efficiently refine and clarify liquids while minimizing waste. This 2-phase separa...

3 phase decanter centrifuge for industrial separation

Optimize your production line with efficient three-phase separation...

Industrial belt press for fruit and vegetable processing

Optimize your juice yield and reduce drying costs in starch and ...

High-performance decanter centrifuge for industrial separation

Optimize your production with a centrifuge solution that ...

Industrial nozzle separator for high solids concentration

Optimize your production with high-performance nozzle separato...

Stainless steel fermentation tank for breweries

Achieve precise control over beer fermentation and maturation with these a...

High speed wraparound label applicator for cylindrical containers

Experience efficient high-speed labelling for cylindr...

Cold glue label applicator for pre-cut labels

Optimize your packaging line with high-speed labeling for a variety of conta...

Stainless steel fermentation tanks

Optimize your fermentation efficiency with stainless steel tanks that provide precise te...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Malt transport and milling system for breweries

Streamline your brewing process with advanced malt transport and milling s...

Tunnel pasteurizer for beer

Optimize your beer production with advanced pasteurization and cooling capabilities, ensuring be...

D.e. pressure Ped tested filter for beer

Ensure optimal beer clarity and taste by filtering out impurities with precise con...

Plate and sheet filter for beer

Enhance your beer’s clarity with a plate and sheet filter designed for sterilization a...

High solids crossflow filter for beer sediment removal

Achieve high-quality, sediment-free beer with minimal oxygen uptak...

Beer blending and carbonation system

Ensure precise blending and carbonation of your beer varieties with a high-speed, PLC-...

Deaeration plant for beer production

Ensure your beer maintains its intended flavor profile and freshness by removing unwan...

Microfiltration system for beer

Ensure optimal beer clarity and taste by integrating versatile microfiltration systems that ...

Capillary membrane filter for beer filtration

Streamline your beer and whisky production by eliminating diatomaceous earth...

Flash pasteurizer for beer brewing

Ensure the longevity and safety of your gassed liquids by integrating continuous high-sp...

Yeast rehydration system for beer brewing

Optimize your beer production with a mobile, single-block system that automates ...

Flex-bräu beer brewing system

Achieve high-efficiency beer production with integrated milling, filtration, and energy-saving...

Carbonation system for Co2 dosing in beer production

Achieve precise carbonation in every beverage batch with seamless CO...

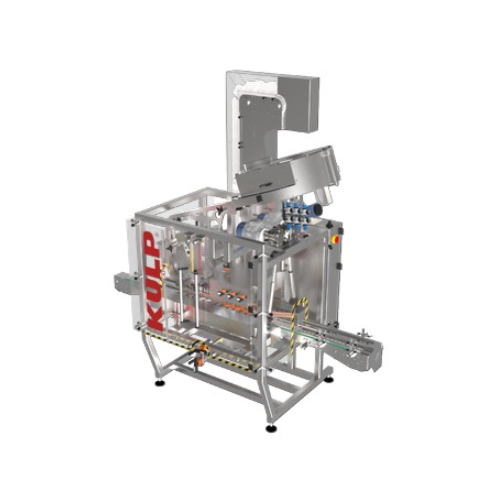

Compact beer brewing system for microbreweries

For breweries aiming to diversify their offerings, this brewing system stre...

Compact brewhouse for microbreweries and brewpubs

Designed for seamless integration into microbreweries, this compact bre...

Automatic aroma and sugar dosing system for breweries

Effortlessly achieve consistent flavor profiles and precise sweetne...

Horizontal plate filtration for beer brewing

Enhance your brewing process with a D.E. filter that ensures high-clarity bee...

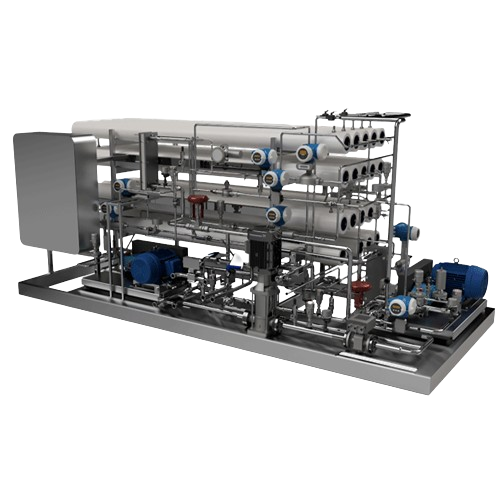

Reverse osmosis with remineralization for drinking water production

Enhance your beverage production with precise water...

Crossflow filtration with ceramic membranes for wines

Enhance filtration efficiency and durability with ceramic membranes...

Industrial sheet filters for diverse liquid filtration applications

Achieve precise liquid filtration with adaptable sh...

Nanofiltration systems for water pretreatment

Achieve precise water quality with advanced nanofiltration systems designed ...

Reverse osmosis systems for industrial water treatment

Achieve optimal water purification in beverage production lines wi...

Industrial crossflow filters with ceramic membranes

Achieve precise filtration with robust ceramic membranes, ideal for h...

Kieselgur filter for wine and lees

Enhance clarity and purity in your beverage filtration process with a system designed to...

Isobaric filling solution for carbonated drinks

Achieve precision filling for carbonated and still beverages with advanced...

Continuous sugar dissolving system for beverage production

Effortlessly transform granulated sugar into a consistent, hi...

Inline carbonation solution for beverages

Achieve precise carbonation control and consistency in your beverage production ...

Cross flow filtration for beer production

Optimize your beer filtration process and minimize product loss with advanced cr...

Kieselgur filter for beer filtration

Achieve crystal-clear beer without compromising flavor through efficient kieselgur fil...

Sheet filters for wine and beer filtration

Enhance your filtration process with reliable sheet filters designed for high-q...

Automated Cip systems for beverage and food industry

Ensure high hygiene standards in your production line with advanced ...

Efficient barley malt crushing with roller mills

Achieve precise particle size control in your processing line with a robu...

Saturation unit for carbonating beverages

Elevate your beverage production with continuous carbonation, ensuring precise g...

Tunnel pasteurizer for beverages

Optimize your beverage production with precise pasteurization control, ensuring product qua...

Cip systems for beverage filling plants

Ensure optimal cleanliness and hygiene in your beverage production line with advanc...

Cleaning solution tanks for beverage production

Achieve superior internal cleaning of beverage containers with our advance...

Flash pasteurizer for beverage production

Ensure beverages maintain quality and safety with precise temperature control an...

Heating and cooling tunnel for beverages

Achieve consistent temperature regulation for beverages, ensuring optimal product ...

Premix system for carbonated beverages

Ensure precise carbonation and blending for your beverage lineup with this advanced ...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

Self-adhesive labelling system for bottles

Enhance your bottling line with a versatile labelling system that supports medi...

Compact wet glue labeling system for low volume production

Achieve precise, high-quality labeling with compact machinery...

High-speed wet glue labelling system

Ensure precise labelling on diverse bottle types with our versatile rotary labelling s...

Compact combined labelling solution for bottling lines

Optimize your bottling line with a versatile, compact labelling so...

Combined wet glue and self-adhesive labeling system

Achieve seamless labeling with combined wet glue and self-adhesive te...

Self-adhesive labeling system for bottles

Streamline your bottling operations with high-precision labeling that enhances p...

Industrial cooling unit for beverages and spirits

Ensure optimal chilling and condensation for beverages and spirits with...

Storage tanks for wine preservation

Ensure optimal preservation of beverages with robust storage solutions featuring precis...

Automatic cross-flow filter for wine

Experience enhanced filtration efficiency with reduced waste, as this cross-flow filte...

Craft beer production plant

For breweries seeking to optimize their production, this customizable brewing solution reduces o...

Manual brewery equipment for entry-level breweries

Designed for aspiring brewers, this compact manual brewing solution si...

Advanced must, juice, and wine turbocooler

Optimize your beverage production with precise temperature control, ensuring co...

Thermostabilizer for beer and wine sterilization

Ensure biological stability in beverages by efficiently inactivating yeas...

Plate filter for beverage sterilization

Achieve absolute clarity and sterilization of your beverages with a versatile plate...

Pre-coat filter with horizontal discs for wine

Ensure optimal clarity in your beverage processes with a solution designed ...

Self-cleaning pre-coat filter for wine filtration

Solve complex filtration challenges effectively with this advanced self...

Grist mill for craft and small breweries

For breweries seeking precision grinding, this compact grist mill excels in millin...

Grist mill for craft breweries and distilleries

Optimize your brewing and distilling efficiency with a compact, high-speed...

Grist mill for brewing and distilling

Achieve optimal grain processing with reduced energy consumption and increased brewho...

Industrial hammer mill for size reduction in food and feed processing

Achieve precise grinding and milling for diverse ...

Malt conditioner for optimal brewing efficiency

Enhance your milling process with precise moisture control, ensuring optim...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Protein and nitrogen analysis system for laboratories

Streamline your nitrogen and protein analysis with precision titrat...

Industrial yeast propagation system

Optimize your beverage and food production with a seamless yeast propagation solution t...

Versatile steam distillation unit for laboratory applications

Achieve reliable analysis of complex samples with this ste...

Inline aeration/oxygenation unit for beer

Ensure consistent fermentation and improve beer quality by achieving precise oxy...

Brewery inline aeration and oxygenation unit

Ensure optimal beer quality by precisely controlling oxygen and air injection...

Cip compact unit for brewery cleaning

Streamline your brewery’s cleaning operations with an all-in-one compact unit t...

Turnkey brewing systems

Streamline your brewing and distilling operations with a comprehensive system that integrates grain h...

Automated beverage canning line

Optimize your beverage packaging with a high-speed canning line that seamlessly integrates f...

Turnkey distilling system for grain to spirit production

Streamline your distillation process with this adaptable system,...

Digital torque viscometer for starch analysis

Experience rapid and precise starch gelatinization analysis with a compact, ...

Mobile Cip carts for brewery cleaning

Streamline your cleaning process with mobile CIP carts that ensure constant temperatu...

Mixer-pasteurizer-carbonator for soft drinks and juices

Optimize your beverage production with a versatile system that se...

Cleaning in place systems for bioreactors

Ensure seamless sanitization with a mobile cleaning system designed to maintain ...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Industrial capping systems for bottling lines

Optimize your bottling process with versatile capping solutions designed for...

Automatic packaging line for bag-in-box

Streamline your bag-in-box production with a seamless solution that ensures precisi...

Automatic case erector for cartonboard packaging

Streamline your packaging process with precision engineering that simplif...

Automatic case erector for cartonboard packaging

Streamline your packaging process and enhance operational efficiency with...

Automated quality control for beverage packaging

Streamline beverage quality control with 24/7 automated analysis, ensurin...

Co2/o2 beverage filling device

Ensure precise beverage analysis by maintaining carbonation integrity with a system that tran...

Packaged beverage analyzer for alcohol and Co2

Ensure precise beverage analysis with a streamlined solution that integrate...

Packaged beverage analyzer for beer, wine, and cider

Ensure precision in beverage quality control with rapid, direct samp...

Depalletising solutions for bottles and containers

Optimize your production line with advanced depalletising solutions th...

Automatic case erector for american cases

Streamline your packaging line with high-speed case erecting, reducing labor cos...

Co2 gas analyzer for beverage bottles

Ensure consistent carbonation levels with precise, non-destructive CO2 measurements i...

Gas analyzer for beverage bottle vacuum level

Ensure precise vacuum level measurement in bottle headspace with non-destruc...

Leak detection system for cans

Ensure the integrity and shelf-life of canned goods with precise leak detection, pressure mea...

In-line leak detection system for beer bottles

Ensure beer quality by detecting leaks and measuring pressure in every bott...

Cap quality inspection system for beverage industry

Ensure flawless cap performance and prevent production disruptions wi...

Empty bottle inspection system for beverage industry

Enhance your production line’s efficiency by detecting defects...

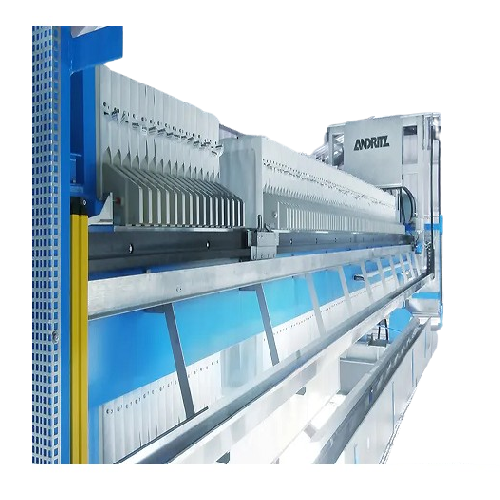

Industrial filter press for dewatering and filtration

Optimize your dewatering and filtration needs with a highly adaptab...

Spiral conveyor for individual bottles and cans

Streamline your production line’s space and layout with a compact co...

Plate type pasteurizer for juice and tea drinks

Ensure optimal heating, sterilization, and cooling for juice and tea produ...

Small bottle linear type beverage filling production line

Optimize your bottling efficiency with a high-speed solution d...

Industrial low temperature water chiller for beverage production

Ensure optimal cooling efficiency and precise temperatu...

Automatic beverage bottle shrink packaging solution

Optimize your beverage packaging process with advanced shrink wrappin...

Automatic bottle cold glue labeling solution

Achieve precise labeling for diverse container types, enhancing your producti...

Industrial centrifuge for beer clarification

Achieve high-clarity beer with minimal oxygen pickup through advanced centrif...

Beer pasteurization module

Achieve reliable microbial reduction and enhance the shelf life of beer and carbonated drinks wit...

Foodec decanter centrifuge for food processing

Achieve high yields and clear liquid separation in your food processing lin...

Automated dry hopping system for large-scale beer production

Achieve seamless dry hopping with reduced oxygen pick-up, o...

Beer sterile filtration system for large breweries

Ensure your beer retains its authentic taste and quality by implementi...

Beer sterile filtration system for large breweries

Achieve 100% bacteria retention and preserve flavor without thermal de...

Intelligent whirlpool system for breweries

Increase your brewery’s yield and efficiency by integrating our advanced ...

Yeast management systems for breweries

Ensure consistent fermentation and enhance product quality with advanced yeast manag...

Double-wall scraped surface heat exchanger

Achieve high-capacity processing with gentle handling for shear-sensitive produ...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Reverse osmosis concentration system for beer and beverages

Optimize transport and storage of beverages by reducing volu...

Modular dosing system for brewing and beverage industry

Ensure precise formulation of beverages by seamlessly integrating...

Beer carbonation system

Achieve consistent and precise carbonation in beverages, ensuring optimal gas dissolution for enhance...

Mobile mixing system for beverages in breweries

Optimize blending and carbonation processes with a mobile solution that st...

Automated Cip station for brewery cleaning

Ensure thorough hygiene and product integrity in your brewing process with a ve...

Water deaeration module for breweries and soft drink manufacturers

Ensure high-quality beverage production by efficient...

Dry hopping system for medium size breweries

Enhance the aroma and flavor of your brews with a system that accelerates the...

Gasketed plate heat exchangers for hygienic applications

Ensure optimal hygiene and thermal efficiency in your processing...

Gasketed plate heat exchanger for hygienic applications

Achieve precise temperature control for sensitive products with a...

High pressure gasketed plate heat exchangers for carbonated beverages

When ensuring high-pressure handling in your past...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Double seat valve for hygienic processing

Eliminate cross-contamination risks and enhance efficiency with a modular valve ...

Air-operated single-seat valves for food and beverage industries

Achieve precise flow control and elimination of downtim...

Single seat valve for hygienic applications

Ensure optimal hygiene and safety with a versatile pneumatic valve designed to...

Gasketed plate-and-frame heat exchangers for industrial applications

Optimize your production with precise thermal mana...

Rotary jet mixer for efficient liquid, gas, and powder mixing

Achieve seamless integration and efficiency in liquid, gas...

Rotary jet head tank cleaning system for food and beverage industry

Reduce your tank cleaning costs by up to 70% with a...

Rotary jet head for hygienic tank cleaning

Ensure efficient, hygienic cleaning with a rotary jet head designed to optimize...

Automated butterfly valve actuator for hygienic processing

Streamline your flow control operations with a robust and mai...

Vacuum breaker valve for Htst pasteurization systems

Prevent vacuum conditions in high-temperature pasteurization systems...

Rotary bottle rinser for high-speed production lines

Ensure thorough cleaning and preparation of containers with a high-s...

High-speed bottle orientator

Efficiently streamline your bottling process by ensuring containers are swiftly and accurately ...

Inspection-rejection station for bottled products

Ensure your bottled and packaged products ship defect-free by automatic...

Industrial weight filler for bottles and jars

Achieve precise product filling with our weight filler system, expertly desi...

Can seamer for high-speed liquid applications

Ensure consistent seal integrity and maximize throughput with this advanced ...

Industrial ejectors for reliable jet pump applications

Enhance process efficiency and reliability with industrial ejector...

Hygienic centrifugal pump for beverage applications

Ensure gentle handling and efficient transfer of sensitive liquids wi...

Self-priming centrifugal pump for Cip solutions

Optimize fluid handling and cleaning processes with versatile, self-primin...

Multi-stage centrifugal pump for hygienic applications

Ensure optimal hygiene and performance in your liquid processing w...

Centrifugal pump for high-pressure systems

Designed for high-pressure systems, this centrifugal pump ensures precise filtr...

Hygienic pump for beverage and pharmaceutical industries

Engineered to meet stringent hygiene demands, this versatile pum...

Centrifugal pumps for hygienic applications

Ensure precise liquid handling for high-stakes applications with this hygienic...

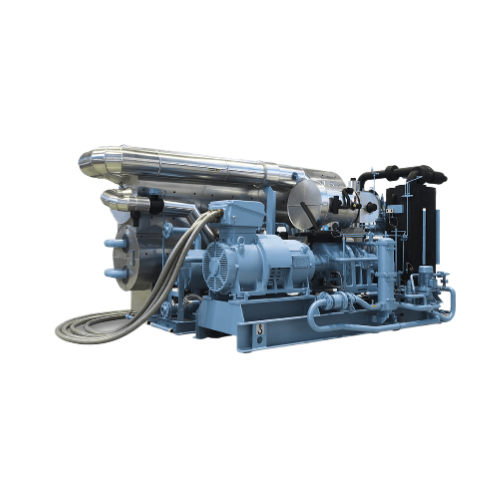

Screw compressor package for efficient industrial cooling

Optimize your cooling processes with a flexible, space-saving ...

Custom-designed membrane filtration systems for industrial applications

Optimize your production with advanced membrane...

Beer recovery unit for breweries

Recover valuable beer from surplus yeast efficiently and integrate seamlessly into your exi...

Cold water deaeration system for beverage production

Achieve exceptionally low residual oxygen levels in beverages, ensur...

Hot water deaeration system for beverage production

Achieve superior product quality by efficiently removing oxygen from ...

Carbonating system for beer and beer mix beverages

Achieve precise carbonation and consistent original wort control for y...

Customized industrial heat pumps

Optimize your industrial processes with versatile heat pumps that recover and utilize waste...

High pressure industrial homogenizer

Enhance liquid formulations with precision and efficiency—our high-pressure homogenize...

Air conveyor for empty Pet bottles

Optimize your bottling line with an advanced air conveyor that reduces energy consumptio...

Reverse osmosis dealcoholization technology

Elevate your beverage production capabilities with advanced dealcoholization t...

Centrifuge for beverage clarification

Elevate your beverage production with enhanced clarification, ensuring your drinks me...

Reverse osmosis dealcoholization technology for beer

Achieve consistent flavor profiles in your non-alcoholic beer produc...

Reverse osmosis beer dealcoholization technology

Achieve precise alcohol removal from beer while preserving flavor integri...

Customized multi-stage gas scrubber systems

Optimize industrial exhaust management with customized multi-stage gas scrubbe...

High-yield fermentation system for raw material processing

Achieve precise control in fermentation with advanced systems...

Combined heating and cooling solution

Optimize your production with a dual-purpose system designed to efficiently manage bo...

Industrial chiller with high part-load efficiency

Optimize your cooling processes with a versatile chiller designed for p...

Cip system for small to medium breweries

Ensure consistent craft beer quality with a modular cleaning solution that seamles...

Cip system for breweries

Optimize your brewing efficiency by integrating a comprehensive cleaning and sterilization system th...

Compressors for Co₂ freezing applications

Optimize your cooling and heating processes with advanced reciprocating compress...

Beer decanter for dry hopped beer clarification

Achieve up to 10% more yield from each batch with this decanter designed s...

High-efficiency ammonia chiller package for industrial applications

Optimize your cooling and refrigeration processes w...

Ammonia chiller for industrial refrigeration

Achieve optimal energy efficiency and reduced operational costs in your cooli...

Glass bottle washing and delabelling system

Effortlessly transform used bottles into pristine, reusable containers with th...

Cold-glue labeller for cylindrical or shaped containers

Achieve seamless high-speed labeling of glass, plastic, and metal...

Modular and combined labeling machines for bottling

Achieve high-speed labeling with unmatched flexibility, combining mul...

Internal wort boiler for precision boiling in brewing

Achieve consistent wort quality with precision boiling, designed to...

Grist milling unit for breweries and distilleries

Optimize your milling process with a versatile unit capable of handling...

Optimal whirlpool vessel for wort treatment

Enhance your wort quality with a vessel that optimizes trub cone formation, re...

Automatic can seamers for food and beverage industry

Ensure airtight sealing of canned goods with precision seamers desig...

Bright beer tanks for breweries

Enhance your beverage production with precise carbonation and conditioning, ensuring excepti...

Cold block process technology for breweries

Optimize your fermentation and storage with integrated cold block process tech...

Fermentation and storage solutions for breweries

Enhance your brewing process with robust fermentation and storage tanks d...

Large-volume stainless steel brewery tanks

Optimize your fermentation and storage operations with precision-crafted tanks,...

Yeast management for brewing high-quality beer

Ensure consistent beer quality and optimize your brewing process with advan...

Membrane mash filter for brewing

Optimize your brewing process with advanced membrane filtration, ensuring maximum yield and...

Efficient mash agitator for breweries

Enhance your mashing process with an agitator designed to optimize heat transfer and ...

Lauter tun for enhanced lautering efficiency and yields

Achieve faster lautering and higher yields with optimized spargin...

Continuous mash filtration system for breweries

Optimize your production line with continuous mash filtration that revolut...

Innovative brewing process for optimized wort quality

Revolutionize your brewing operations by optimizing subprocesses fo...

Carbonated beverage can filler - 4 spout open fill

Optimize canning carbonated beverages while minimizing CO2 loss with t...

Level bottle filler for wine and spirits

Achieve consistent fill levels with precision sensor technology, ideal for ensurin...

Counter pressure filler for carbonated beverages

Ensure optimal carbonation and minimal oxygen exposure during bottling, e...

Counter pressure can filler for carbonated beverages

Achieve precise carbonation levels and minimal oxygen exposure in ca...

Counter pressure bottle filler for carbonated beverages

Maintain carbonation levels while filling bottles efficiently, en...

Counter pressure bottle filling system for carbonated beverages

Enhance your bottling efficiency with a versatile counte...

Carbonated beverage can filler for beer and kombucha

Looking to enhance your beverage production efficiency? This can fil...

Cip system for bottling line sanitation

Ensure optimal hygiene in your bottling operation with efficient CIP systems that i...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

High flow rate Fibc dischargers for wastewater treatment

Optimize your material handling with efficient, dust-proof disch...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Cushioned pneumatic vibrators for bulk solids conveying

Streamline your material handling with precision vibration contro...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

High capacity vertical conveying for flour

For consistent, high-speed handling of delicate and powdery materials, this eng...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Vibratory outlet hopper for bulk solids discharge

Reduce material handling challenges with highly efficient vibration tec...

Wet spent grains pre-dewatering system

Optimize your brewery operations with a dewatering system that efficiently reduces m...

High performance industrial pasteurizers

Enhance your liquid processing with fully autonomous pasteurizers that ensure opti...

Centrifugal separators for liquid/liquid/solid separation

Achieve efficient separation and clarification for diverse app...

Turnkey stainless steel tanks

Optimize your liquid processing with versatile stainless steel tanks designed for efficient st...

Vessel dome fittings for tank protection

Ensure seamless production by preventing tank damage due to overpressure or vacuum...

Industrial chiller systems for processing cooling

Optimize your production line with advanced chiller systems designed to...

Industrial water recycling system

Reduce excess water consumption in your process line by recycling and reusing up to 96% o...

Hygienic plate heat exchanger

Optimize temperature control for liquid processing with precision-engineered heat exchangers, ...

Holding time verification for pasteurizers

Ensure your pasteurized products meet safety standards by verifying they’...

Storage tank integrity testing

Prevent costly contamination and streamline your operations with advanced tank integrity test...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Liquid sugar storage tank

Ensure seamless liquid sugar management in your production line with advanced storage solutions de...

Filling system for gable top packages

Achieve precise, cost-effective filling with reduced energy consumption for chilled l...

Semi-automatic capping solution for beverage and cosmetic bottles

Streamline your bottling process with versatile bench...

Vacuum bottling equipment for wineries and breweries

Optimize your bottling process with a vacuum solution that fills up ...

Vacuum filler for wine and oils

Optimize your beverage bottling process with a compact vacuum filler designed for precise le...

Industrial decanter centrifuge for solids separation

Optimize your production line with high-speed decanter centrifuges t...

Round vibratory separation equipment - bag dump screener system

Enhance your material handling and safety by efficiently...

Industrial stainless steel filters and strainers

Optimize your liquid processing with precision filtration and straining, ...

Falling film plate evaporators for fruit juice concentration

Achieve precise concentration of liquid products with minim...

Tank washers for barrel and vat cleaning

Effortlessly maintain hygiene and efficiency in your production line with tank was...

Beer storage tanks for post-fermentation maturation

Ensure optimal beer quality with precision-controlled cooling and car...

Integrated linear blowing and filling system for Pet containers

Streamline your PET container production with integrated...

Integrated preform production and bottling system for Pet bottles

Achieve seamless production of PET bottles, from pref...

Isobaric filler for glass and Pet bottles

Achieve precise liquid filling with enhanced operational flexibility and hygiene...

Cip sanitizing unit for food and beverage production

Ensure meticulous hygiene with a compact unit designed for seamless ...

Degassing and mixing unit for beverage production

Ensure precise beverage formulation and maintain high quality standards...

Continuous pasteurization unit for beverages

Optimize beverage shelf life and safety with this versatile pasteurization un...

Cartoning solutions for beverage and food industries

Optimize your packaging line with a versatile range of cartoning sys...

Large size container linear blow molder

Optimize your large-scale production of containers with a solution designed to stre...

Linear blowing systems for Pet bottle production

Ideal for producers seeking versatile container solutions, this system en...

Volumetric filler for Pet bottle beverages

Experience seamless integration into your bottling line with this advanced volu...

Isobaric filling system for carbonated beverages in Pet bottles

Achieve precise carbonation levels and seamless integrat...

Slurry blender for ethanol production

Optimize your ethanol and beverage alcohol production with a solution that ensures pr...

Aseptic tank for liquid food storage

Store and maintain the sterility of low and high acid liquid foods while ensuring prod...

Continuous sugar dissolver for high brix solutions

Optimize your beverage production with a system that dissolves sugar u...

Pasteurization solution for food liquids

Extend the shelf-life of your liquid products while maintaining their quality with...

Custom syrup preparation systems

Optimize your beverage production with precision-engineered syrup preparation systems desig...

Uht sterilization solution for liquid food products

Enhance your liquid food processing with reliable UHT sterilization, ...

Industrial solutions for beverage mixing and carbonation

Optimize your beverage production with precise mixing and carbon...

Horizontal Beverage Can Cartoner

Cans have many advantages over bottles when it comes to packing, for example, your craft be...

High-frequency vibratory mixer

Mixing liquid products by stirring method generates heat from friction and shear forces. This...

Mass flow air knife drying system for cans

For large-scale production of canned beverages, line throughput and efficiency ...

Beer pasteurizer

Contamination and cross-infection by microorganisms is a major risk in the production of foods and beverages....

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

Craft Beer Pasteurizer

Pasteurization of craft beers in breweries is very important to ensure the maintenance of taste and ex...

Multifunction case packer for bottles and jars

New ways of packaging products are popping up all the time on the market. T...

Wrap-around case packer for cans or bottles

When it comes to beer packaging, most of the manufacturers use plain box carto...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Medium scale round can seamer

Automatic seaming of cans of craft bear can be quite the hassle with the movement from the cen...

Wraparound case packer

Packaging companies need to pay attention to personalization in shape and design in addition to the at...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Linear machine for wraparound label

Wraparound labels allow you to offer detailed information using a small space or fit ex...

Industrial crate washing machine

In order to meet the increasing demand of the beverage industry, it’s essential to find a c...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Air knife system for bottling lines

Wet containers are unacceptable and can be problematic in the food and beverage industr...

Inline syrup room

The beverage industry requires high-quality syrup. Soft drinks, fruit juices, still drinks, ice tea, flat o...

CIP system for beverage

Clean-in-place operations are a mandatory part of food and beverage processing which cannot fail. How...

Flash pasteurizer for beer

The food and beverage industry are faced with constant challenges. Contamination and cross infect...

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

Shell and tube heat exchanger

Heating, cooling and tempering are important processes in the production of many products acro...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

High-speed unscrambler for large bottles

Large volume plastic bottling plants need high-speed unscramblers suitable for lar...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Low-speed unscrambler

Smaller plastic bottling lines need a lower cost, lower volume unscrambling machine that maintains gent...

Full crate inspection system

State of the art crate inspection system that uses a laser camera system to see if the bottles ...

High-precision X-ray fill level controller

High-speed, high precision X-ray system to inspect containers that are difficul...

Advanced residual liquid inspection system

Advanced and easy to use inspection system that eliminates the risk of residual...

Residual liquid inspection system

Inspection system that eliminates the risk of residual liquid, water or left over drink i...

Empty bottle height sorting system

An empty bottle sorting system that uses the light barrier technology. It detects bottle...

Empty crate inspection system

Extensive and much-differentiated inspection of both the crate and the bottle that allows you ...