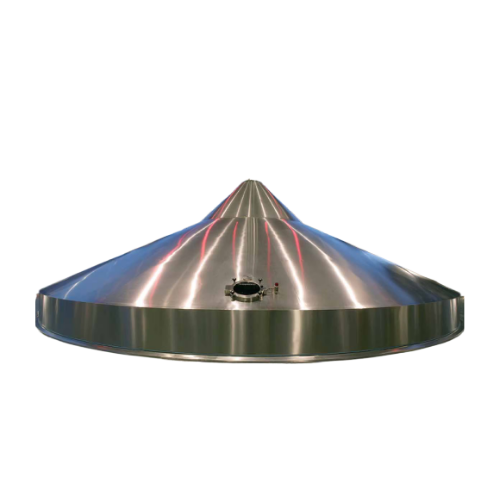

Advanced lauter tun for brewing efficient wort

Optimize your brewing process with a cutting-edge lauter tun that enhances extraction efficiency and boosts brewhouse capacity, ensuring high-quality beer production with reduced turbidity and consistent results.

Optimizes Lautering and Enhances Extraction Efficiency

The GEA LAUTERSTAR® 2.0 from GEA Brewery Systems revolutionizes the lautering process with its multifunctional capabilities, seamlessly integrating into brewery operations. This lauter tun system employs a geometrically optimized wort run-off and double-shoe raking knives, enhancing extraction efficiency while minimizing turbidity in beer production. It supports up to 14 brews per day, catering to a wide spectrum of beer styles like lager, ale, and stout. Equipped with Multifunctional Lautering Management (MLM), it automatically adjusts processes to varying raw material qualities, ensuring consistent high yields and short lautering times. Designed for high-capacity continuous operations, the LAUTERSTAR® 2.0 optimizes energy usage and offers customization options, enhancing productivity and sustainability in brewing and beverage industries.

Benefits

- Enhances beer quality with high extraction efficiency and low turbidity.

- Increases brewery capacity by allowing up to 14 brews per day.

- Automatically adjusts to raw material variations, ensuring consistent quality.

- Reduces operational costs with optimized energy usage.

- Offers flexible customization to meet specific production needs.

- Applications

- Food, Beverage, Brewing

- End products

- Craft beer, Lager, Stout, Porter, Beer, Ale

- Steps before

- Mashing, Heating, Mixing, Mash Transfer

- Steps after

- Boiling, Wort Cooling, Fermentation, Filtration

- Input ingredients

- raw materials, grains, mash

- Output ingredients

- wort, low-turbidity wort

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Brews per day

- Up to 14

- Wort turbidity

- Very low

- Extract yield optimization

- High

- Total cost of ownership (TCO)

- Low

- Automation

- Multifunctional Lautering Management (MLM)

- Yield increase

- Up to 2 percentage points

- Lautering time

- Shortened

- Bed loading

- Optimized

- Wort concentration

- Control enabled

- Automation level

- Multifunctional Lautering Management (MLM)

- Brews per day

- Up to 14

- Batch vs. continuous operation

- Batch

- Cleaning method

- CIP

- Energy efficiency

- Optimized for low total cost of ownership (TCO)

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customizable

- Diameter

- Variable, as per customer requirements

- Tank shape

- Cylindrical

- Discharge method

- Optimized for run-off

- Raking knives

- Double-shoe

- Control panel type

- Automated / Multifunctional

- Integration possibilities

- Existing system upgradation

- Dimension settings

- Customizable diameter and bed loading

- Brewing capacity

- Up to 14 brews per day