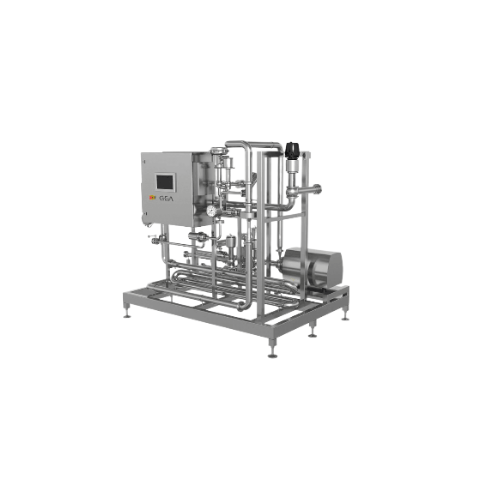

Carbonating system for beer and beer mix beverages

Achieve precise carbonation and consistent original wort control for your beer and mixed beverages with our advanced mixing solution, ensuring optimal taste and quality in every batch.

Mixes and Carbonates Beverages with Precision

The GEA DIMIX-B Mixer/Carbonator is engineered specifically for the brewery and beverage industries, offering unparalleled precision in mixing and carbonation. This system ensures consistent quality and optimal CO2 integration by utilizing high-precision components including flow meters, monitoring valves, and analyzing units. Designed for continuous operation, it enhances original wort and carbonation accuracy through a single-stage carbonation process. With the integration of a saturator and a saturating pipe section, CO2 is finely dispersed for complete bonding, ensuring uniform carbonation across your product range, from lagers and ales to radlers and hard seltzers. The DIMIX-B operates with a user-friendly interface, facilitating recipe storage and real-time monitoring, making it easily adaptable for different operational demands. Furthermore, it seamlessly integrates with GEA VARIDOX systems for water deaeration, allowing for full system optimization and efficiency in beverage production.

Benefits

- Ensures product consistency and quality with precise carbonation control.

- Minimizes operational costs through seamless integration with existing systems.

- Enhances production efficiency with continuous, automated processing.

- Adapts to diverse beverage formulations, supporting a wide range of products.

- Simplifies operational complexity with a user-friendly interface and real-time data monitoring.

- Applications

- Carbonated beverages, Beer, Beer mix beverages

- End products

- Carbonated ale, Lager, Radler, Hard seltzer, Ale

- Steps before

- Wort preparation, Water deaeration, Ingredient mixing

- Steps after

- Quality control, Packaging, Labeling, Distribution

- Input ingredients

- beer, deaerated water, CO2

- Output ingredients

- carbonated beer, beer mix beverages

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- CO2 Metering

- Yes

- Original Wort Accuracy

- Up to 0.05% original gravity

- Carbonation

- Single-stage to saturation

- Operation

- Easy operation

- Flow Metering

- Beer, deaerated water

- CO2 Monitoring

- Direct monitoring

- Automation

- Controller for setpoint-to-actual comparison

- Automation level

- PLC

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- CIP

- Original gravity accuracy

- up to 0.05%

- Single-stage carbonation

- Up to saturation value

- CO2-content control

- Direct monitoring

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Designed for space optimization

- Control panel type

- Integrated operating unit

- Discharge method

- Continuous flow via monitoring valves

- Control panel type

- Operating unit

- Integration possibilities

- Compatible with GEA VARIDOX-C and GEA VARIDOX-H

- Footprint

- Compact, shop-tested aggregate