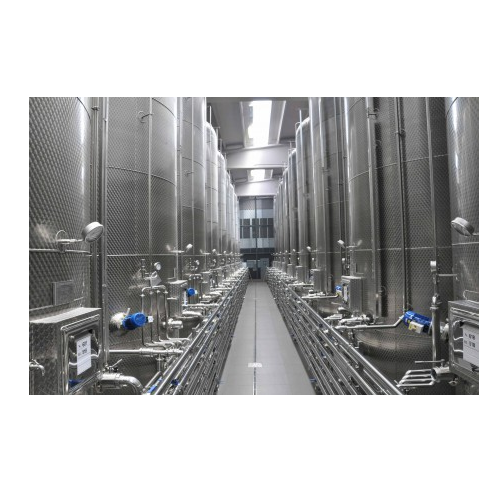

Beer fermentation tanks

Ensure optimal fermentation climate control for all beer styles with customizable tanks designed for precise temperature management and storage, enhancing flavor and quality.

Controls Fermentation and Storage Temperature

Engineered by SIRIO ALIBERTI S.r.l., these AISI 304/306 stainless steel fermentation and storage tanks are designed for craft breweries, microbreweries, and large-scale brewers. They excel in maintaining the precise conditions required for fermenting and storing a wide range of beers, including ales, lagers, stouts, and IPAs. Featuring integrated glycol circulation through insulated jackets, these tanks ensure consistent temperature control throughout the fermentation process, crucial for quality beer production.

With customizable designs to fit specific brewing operations, the tanks support both batch and manual operations. They are built for durability, ensuring long-term reliability in brewery environments. The option to add refrigeration or heating pockets offers flexibility for varying brewing processes, while the construction materials provide excellent corrosion resistance. Although specific capacity details require consultation, the tanks are adaptable for a range of fermentation volumes. Designed with hygiene and safety in mind, they facilitate easy cleaning and maintenance, ensuring compliance with industry standards.

Benefits

- Ensures consistent beer quality through precise temperature control.

- Customizable design accommodates varying production capacities and brewery layouts.

- Enhances operational efficiency, reducing energy usage with glycol circulation system.

- Durable stainless steel construction withstands harsh brewing environments.

- Simplifies maintenance with easy-to-clean surfaces and integrated safety features.

- Applications

- Beverages, Beer

- End products

- Pilsner, Lager, Belgian dubbel, Kölsch, Ipa (india pale ale), Mead, Stout, Saisons, Wheat beer, Ale, Porter

- Steps before

- Ingredient Preparation, Wort Boiling, Yeast Addition

- Steps after

- Beer Maturation, Carbonation, Filtration, Packaging

- Input ingredients

- wort, yeast

- Output ingredients

- beer, carbon dioxide

- Market info

- Material

- AISI 304 / 306 stainless steel

- Temperature Control

- Low-temperature glycol solution circulation

- Temperature Range

- Customizable

- Customizable Design

- Made to measure

- Cooling

- Refrigerant circulation pockets

- Heating Option

- Heating fluid circulation pockets

- Temperature control method

- Glycol circulation through hollow spaces

- Automation level

- Manual / PLC / SCADA

- Cooling medium

- Glycol solution

- Heating option

- Refrigerant or heating fluid circulation

- Batch vs. continuous operation

- Batch

- Fermentation type

- Batch Fermentation

- Cleaning method

- Clean in Place (CIP)

- Hygienic Design

- Yes

- Corrosion Resistance

- High (AISI 304 or 306 Stainless Steel)

- Cleanability

- Easy to clean

- Temperature Resistance

- Compatible with low-temperature glycol solution

- Non-reactivity

- Non-reactive with beer and fermentation components

- Durability

- Suitable for long-term use

- Storage and Fermentation

- Beer

- Beer Maturation

- Post-fermentation stage

- Tank shape

- Cylindrical

- Tank material

- AISI 304 or 306 stainless steel

- Cooling method

- Low-temperature glycol solution circulation

- Refrigerant circulation

- Hollow spaces in the tank cylinder

- Customization

- Made to measure

- Pockets for temperature control

- On cylinder or bottom of the tank

- Fermentation temperature control

- By glycol solution

- Material

- AISI 304 or 306 stainless steel

- Temperature Control

- Special hollow spaces with glycol solution

- Customization

- Made to measure

- Refrigerant Circulation Pockets

- Cylinder or bottom installation