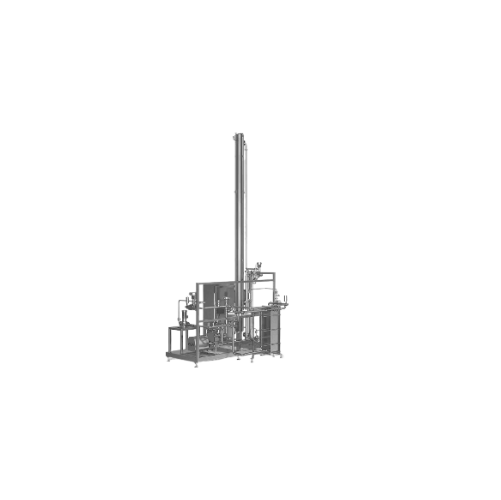

Hot water deaeration system for beverage production

Achieve superior product quality by efficiently removing oxygen from your beverage production water, minimizing taste and shelf-life issues.

Reduces Oxygen Levels in Beverage Processing

The GEA VARIDOX-H from GEA is a hot water deaeration system designed to significantly reduce the oxygen content in beverage processing, enhancing both taste and shelf life. Operating by feeding water at 72°C into a deaeration column, it utilizes countercurrent CO2 or N2 to expel oxygen effectively. This system suits a range of applications including beer, carbonated beverages, and bottled water, achieving residual oxygen levels as low as 0.005 mg/l. Supporting continuous high-speed operations, it offers a processing capacity between 20 hl/h and 1,000 hl/h, integrating seamlessly with existing production lines. Energy efficiency is optimized through a 90% heat recovery rate. Constructed from 1.4301 or EPDM materials, it ensures corrosion resistance and longevity. Compliance with stringent quality standards makes it an asset for beverage producers, breweries, and water treatment facilities. Maintenance is simplified with an integrated CIP system, minimizing downtime and operational costs.

Benefits

- Enhances product quality by achieving ultra-low residual oxygen levels, preserving taste and freshness.

- Optimizes energy use with 90% heat recovery, lowering operational costs.

- Minimizes CO2 consumption for cost-effective and sustainable operations.

- Provides flexibility with customizable flow rates from 20 hl/h to 1,000 hl/h.

- Reduces maintenance time with integrated CIP system for efficient cleaning.

- Applications

- Brewery, Beverages, Water, Beer

- End products

- Carbonated beverages, Bottled water, Enhanced water beverages, Non-alcoholic beer, Flavored water

- Steps before

- Water Pre-treatment, Pre-heating

- Steps after

- Cooling, Filling, Redilution, Packaging

- Input ingredients

- water, CO2, oxygen

- Output ingredients

- deaerated water, low oxygen content water

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Residual Oxygen Content

- , lt

- 0.02 mg/l (20 ppb)

- Residual Oxygen Content (Enhanced)

- , lt

- 0.01 mg/l (10 ppb) or,lt

- 0.005 mg/l (5 ppb)

- Water Pasteurization

- , ge

- 25 PE

- Heat Recovery

- , ge

- 90%

- Flow Rate

- 20 hl/h to 1, 000 hl/h

- Water Inlet Pressure

- 2 bar

- Control Air Pressure

- 6-8 bar

- CO2 Inlet Pressure

- 6-8 bar

- CO2 Consumption

- 0.05 g/l

- CO2 Quality

- , gt

- 99.998% purity

- Material

- 1.4301 / EPDM

- Working mechanism

- Hot water deaeration with countercurrent CO2

- Integrated steps

- Degassing, heat recovery, cooling

- CIP Principles

- VARIDOX CIP with cleaning solution through product lines

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- PLC

- Changeover time

- Short installation time - pre-assembled unit

- Energy efficiency

- ≥90% heat recovery

- Cleaning method

- CIP

- Degassing temperature

- 72°C

- Compact footprint

- Pre-assembled unit

- Discharge method

- Countercurrent CO2(N2)

- Control panel type

- Automated sensors

- System configuration

- Column-based deaeration

- Control panel type

- PLC-controlled

- Integration possibilities

- SCADA compatible

- Customization of automation level

- Manual / PLC / SCADA

- Customization of flow rates

- 20 hl/h to 1, 000 hl/h

- Deaeration column height

- Adjustable for lower oxygen levels