Catalyst characterization analyzer

Achieve precise catalyst characterization and optimization with advanced techniques like chemisorption and temperature programmed reactions, enabling refined research and development in catalytic processes.

Conducts Catalyst Evaluation and Gas Adsorption Analysis

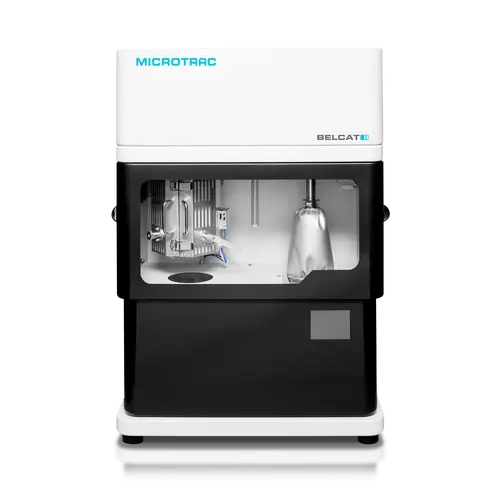

The BELCAT II Catalyst Characterization Analyzer from Microtrac Retsch GmbH is a fully automated benchtop solution optimized for in-depth catalyst analysis and gas adsorption measurements. This equipment excels in pulse chemisorption, temperature programmed desorption (TPD), reduction (TPR), oxidation (TPO), and reaction (TPReaction), providing precise catalyst evaluation for varied industries such as chemical, petrochemical, and material science.

The BELCAT II is designed for the rigorous demands of research laboratories and catalyst developers, ensuring accurate results for applications in catalytic converters, lithium-ion battery cathodes, and proton exchange membrane fuel cells, among others. It features precise gas control through high-performance mass flow controllers and an automatic gas injection system, ensuring reproducibility. The pulse loop, equipped with a temperature/pressure sensor, enhances accuracy in catalytic studies.

Covering a wide temperature range up to 1,100°C and supporting conditions as low as -120°C with the optional CATCryo II, BELCAT II handles both solid and gas product types with versatility. Configurations allow for the usage of numerous gases, including He, Ar, and H2, enhancing its adaptability across various research scenarios. Built with corrosion-resistant materials, it maintains integrity under challenging conditions.

The BELCAT II’s integration into production lines is seamless, offering quick cooling features and requiring minimal manual intervention, thus streamlining research and development operations. Its compact footprint and comprehensive capabilities make it an invaluable tool for advancing material innovations while reducing setup and maintenance time.

Benefits

- Ensures precise catalyst performance data with consistent and reproducible results.

- Minimizes manual intervention through fully automated operation, saving time and reducing labor costs.

- Adapts to diverse research needs with extensive gas and temperature compatibility.

- Compact design optimizes laboratory space usage.

- Built with corrosion-resistant materials for durability in aggressive chemical environments.

- Applications

- Battery materials, Ceramics, Fibers, Fuel cells, Separation membranes, Polymer materials, Magnetic materials, Pigments, Catalysts, Cement

- End products

- Polyethylene, Lithium-ion battery cathodes, Ferrite magnets, Gas separation membranes, Porcelain tiles, Carbon fibers, Portland cement, Catalytic converters, Iron oxide pigments, Proton exchange membrane fuel cells

- Steps before

- Purification of gas, Preparation of catalyst samples, Gas mixing setup, Temperature/pressure calibration

- Steps after

- Data analysis, Result validation, Catalyst performance evaluation, Reporting

- Input ingredients

- He, Ar, N2, O2, H2, CO, CO2, NH3, N2O, NO, H2O, CH3OH, C2H5OH, toluene, benzene

- Output ingredients

- analyzed gas composition, catalyst characterization results, surface area data, pore size distribution data, catalytic activity evaluation

- Market info

- Microtrac is known for its expertise in particle size and shape analysis, providing innovative measurement solutions used in various industries to ensure product quality and consistency. Their equipment is recognized for precision and reliability in laboratory and industrial settings.

- Automation

- Fully automated

- Gas control

- Precise with three high-performance mass flow controllers

- Gas injection system

- Automatic calibration

- Temperature range

- Maximum 1, 100°C

- Cooling time

- 30 minutes (400°C->50°C)

- Dimensions

- 500 x 750 x 500 mm

- Weight

- 80 kg

- Power supply

- AC 100-120 V / 200-240 V, 1, 300 W, 50 / 60 Hz

- Measurement principle

- Dynamic flow method

- Detector type

- Semi-diffusion type 4-element thermal conductivity detector (TCD)

- Measurement / pretreatment port

- 1

- Injection gas

- He, Ar, N2, O2, H2, CO, CO2, NH3, N2O, NO, etc.

- Dosing gas

- Carrier

- Mass flow controller capacity

- Carrier

- Cryo option

- -120°C supported

- Vapor injection (optional)

- H2O, CH3OH, C2H5OH, toluene, benzene, etc.

- Utility gas pressure

- Measurement gas

- Joint type

- 1/8” Swagelok connection

- Working Mechanism

- Dynamic flow method

- Automation Level

- Fully automated

- Pretreatment Capability

- Included

- Batch vs. Continuous Operation

- Batch

- Gas Control

- Precise control by mass flow controllers

- Temperature Regulation

- Up to 1, 100°C, quick cooling

- Injection System

- Precise automatic gas injection

- Pulsed Chemisorption Capability

- Yes

- Temperature Programmed Desorption

- Yes

- Temperature Programmed Reduction

- Yes

- Temperature Programmed Oxidation

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- CE certified

- yes

- Machine footprint

- 500 x 750 x 500 mm

- Weight

- 80 kg

- Compact footprint

- 500 x 750 x 500 mm

- Control panel type

- Automated control system