Ultra-fine powder grinding with jet mills

Achieve unparalleled fineness and purity in powder production with cutting-edge jet mill technology, ideal for processing complex materials without contamination or wear, making it essential for precision-dependent industries seeking efficient, high-quality grinding solutions.

Grinds and Comminutes Ultra-Fine Powders

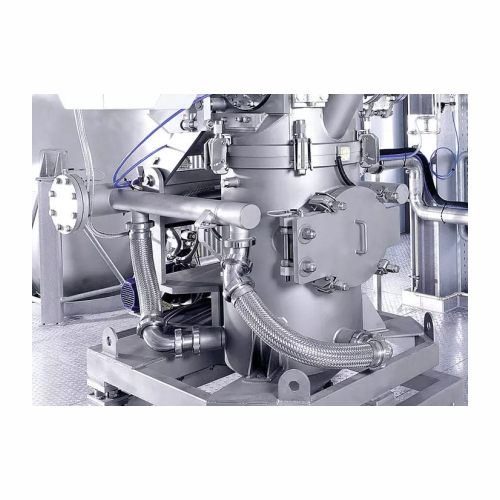

Hosokawa Alpine’s Jet Mills, including the Aeroplex AS and Alpine Microburst AMB, offer precise ultra-fine grinding solutions tailored for pharmaceuticals, fine chemicals, and minerals. Their unique fluidised bed and spiral jet designs ensure contamination-free processing by eliminating mechanical grinding tools. Capable of achieving particle sizes down to d97= 1 µm, these mills cater to applications across multiple industries, providing contamination-sensitive grinding for products like antibiotics and semiconductor materials. Engineered with integrated classifiers, they enhance particle size control while efficiently separating materials from the grinding gas. With the flexibility to handle high-purity and heat-sensitive materials, these mills integrate seamlessly into continuous production lines, leveraging PLC controls for optimal operation. Available in corrosion-resistant materials, they adhere to GMP and FDA standards, ensuring compliance in demanding applications. The integration of easy-to-clean features supports swift maintenance, guaranteeing consistent production with minimal downtime. Custom configurations and extensive engineering support further refine the solution to your specific production needs.

Benefits

- Achieves ultra-fine particle sizes for high-quality end products.

- Ensures product purity by eliminating contamination through non-contact grinding.

- Integrates seamlessly into existing processes with flexible design options.

- Reduces energy usage through efficient air jet technology.

- Complies with GMP and FDA standards for reliable pharmaceutical processing.

- Applications

- Ceramics, Metal powders, Fine chemicals, Powder coatings, Silica, High-purity materials, Antibiotics, Glass, Pesticides, Minerals, Toners, Heat-sensitive materials, Pigments, Talc, Pharmaceuticals

- End products

- Cosmetic pigments, Pharmaceutical grade silica, Laser printer toner, Metal additive powders, Insecticide dust, Antibiotic tablets, Automotive paint powder coatings, Ceramic tiles, Temperature-sensitive film materials, Semiconductor high-purity silicon, Mineral flour, Talcum powder, Fine-grade chemical compounds, Optical glass components

- Steps before

- Purification, Drying, Grinding, Pre-crushing

- Steps after

- Separation, Fractionation, Particle size analysis, Sterilization, Packing

- Input ingredients

- mineral flour, talc, silica, pesticide, coarser products, fibrous products, heat-sensitive materials, toner, powder coating, pigments

- Output ingredients

- ultra-fine powder, contamination-free powder, highly pure powder, sharp particle size distribution, pharmaceutical substances, antibiotics, fine chemicals

- Market info

- Hosokawa Alpine is known for its expertise in manufacturing advanced process equipment and systems for powder and particle processing technology. It has a strong reputation for innovation, quality engineering, and customer-focused solutions in various industries.

- Grinding Gas Pressure

- High Pressure

- Grinding Gas Type

- Compressed Air

- Particle Size Range

- 1 µm to 200 µm

- Grinding Chamber Type

- Spiral / Fluidised Bed

- Classifier Type

- Integrated High-Performance Classifier

- Material Compatibility

- Very Hard Materials

- Automation

- Available

- Contamination-Free Grinding

- Yes

- Temperature-Sensitive Material Capability

- Yes

- Energy Efficiency

- High

- Working Mechanism

- Jet milling with gas stream

- Particle Size Reduction

- Colliding particles in a gas stream

- Automation Level

- PLC / SCADA

- Product Handling

- No mechanical contact

- Material Purity

- Contamination-free

- Batch vs. Continuous Operation

- Continuous

- Cleaning Method

- Easy to clean/sterilize

- Flow Type

- Spiral or fluidized bed

- Temperature Sensitivity

- Handles heat-sensitive materials

- Grinding Gas Use

- Compressed air

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 1–1000 µm