Crossflow filtration with sieve filter for difficult suspensions

Achieve precise separation and recovery in challenging conditions with crossflow filtration, ensuring consistent quality and high purity for high viscosity suspensions and complex mixtures.

Continuously Screens and Separates High Viscosity Suspensions

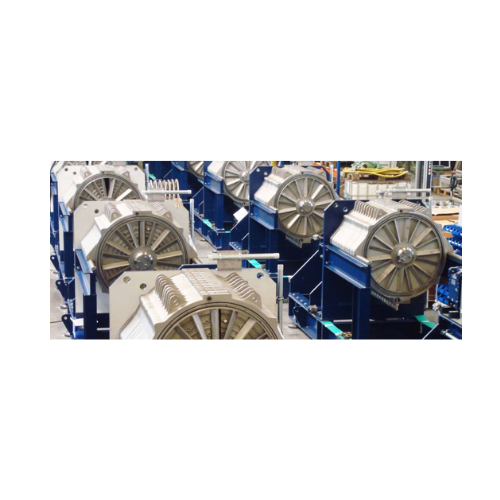

The BoCross MicroScreen from BOKELA is a dynamic sieve filter designed for handling high viscosity suspensions and challenging separation tasks. Utilizing dynamic crossflow technology, it effectively screens and separates particles with remarkable precision. Ideal for the chemical sector, this equipment supports manufacturers of plastic intermediates, pigments, fillers, and dyes by offering continuous filtration with sharp cut points. Capable of operating under pressures of up to 6 bar and temperatures up to 100°C, it processes complex slurries into particle-free filtrates and highly concentrated retentates. The BoCross MicroScreen features automatic operation and can be seamlessly integrated into existing process automation systems. Its asymmetric metallic filter media permits efficient backwashing, contributing to reduced downtime and maintenance needs. Customizable filter sizes from 0.1 m² to 12 m² allow tailored solutions, supporting diverse production scales.

Benefits

- Enhances production efficiency by achieving precise particle separation with minimal product loss.

- Reduces operational costs with fully automated, continuous operation.

- Accommodates high viscosity slurries, expanding processing capabilities for diverse applications.

- Minimizes maintenance downtime with self-cleaning backwashable filter media.

- Offers flexible integration into existing systems, ensuring seamless process adaptation.

- Applications

- Dyes, Chemical sector, High viscosity suspensions, Fillers, Catalyst recovery, Pigments, Plastic intermediates

- End products

- Polyurethane resins, Titanium dioxide particles, Phthalocyanine dye formulations, Zeolite catalyst granules, Paint additives, Polyethylene terephthalate (pet) granules, Silica filler powders

- Steps before

- Concentration, Thickening

- Steps after

- Product Classifying, Particle Separation, High Purity Production

- Input ingredients

- suspensions, solids, viscous suspensions, highly concentrated suspensions, catalysts, plastic intermediates, pigments, fillers, dyes

- Output ingredients

- classified suspensions, recovered solids, fine grain fractions, particle-free filtrates, high purity products, narrow particle size distribution, high concentrated concentrate, cleared suspensions

- Market info

- BOKELA is known for its expertise in engineering and manufacturing filtration technology and equipment, particularly for solid-liquid separation processes in various industries, offering innovative, high-performance solutions with a strong reputation for reliability and efficiency.

- Filter Area

- 0.1 m² to 12 m²

- Operating Pressure

- Up to 6 bar (a)

- Operating Temperature

- Up to 100 °C

- Filtration Type

- Dynamic Sieve Filtration / Dynamic Precoat Filtration

- Cut Size

- 5 µm

- Filter Media

- Asymmetric Metallic Media

- Drive

- 3 kW to >45 kW

- Number of Modules

- 5 to 12

- Automation

- Fully Automatic

- Working mechanism

- Dynamic crossflow filtration

- Integrated steps

- Dynamic sieve filtration and dynamic precoat filtration

- CIP/SIP

- Backwashable, intermittent backwashing

- Batch vs. continuous operation

- Continuous operation

- Hermetic process

- Yes

- Flexibility

- High flexibility with product characteristic changes

- Automation level

- Fully automatic

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- Good

- Density/particle size

- Wide range compatibility

- Cleanability

- Excellent

- Viscosity

- High viscosity tolerance

- Particle Size

- 5–100 µm

- Solids Concentration

- High concentration allowed

- Temperature

- Up to 100°C (higher in special cases)

- Operating Pressure

- Up to 6 bar (a)

- Suspension Type

- High viscous or highly concentrated

- Recovery Type

- Complete recovery of solids

- Interfering Grain Fraction

- Separation of interfering coarse or fine grain

- Filtration Type

- Dynamic sieve and precoat filtration

- Filter Area

- 0.1 m² to 12 m²

- Filter Diameter

- 145 mm, 375 mm, 850 mm

- Operating Pressure

- Up to 6 bar

- Operating Temperature

- Up to 100 °C

- Number of Modules

- 5, 10, 12

- Drive Power

- 3 kW to >45 kW

- Filter Media

- Asymmetric metallic media

- Control Panel Type

- PLC-controlled

- Integration Possibilities

- Process Automation

- Modular Construction

- Hermetically Sealed

- Filter Media Type

- Asymmetric Metallic

- Operating Pressure

- Up to 6 bar (a)

- Operating Temperature

- Up to 100 °C

- Heating/Cooling System

- Integrated in Modules