Crossflow filtration for microfine to nanoscale suspensions

Optimize your production line with advanced crossflow filtration, achieving high solids concentration and clear filtrate even at elevated viscosities. Perfect for handling challenging microfine suspensions, this technology ensures efficient separation and washing processes, streamlining operations while maintaining product integrity.

Concentrates and Clarifies High-Viscosity Suspensions

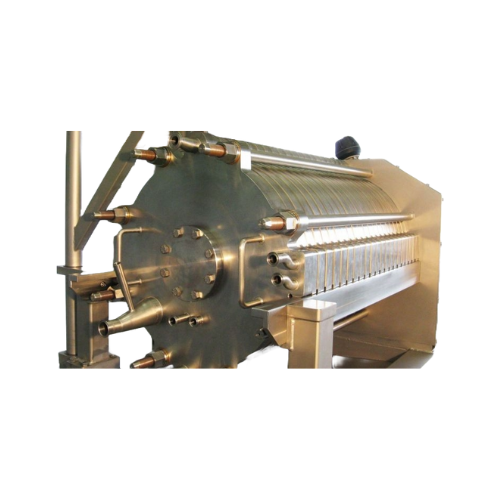

The BoCross Dynamic from BOKELA offers a cutting-edge solution for filtration challenges in industries such as plastics, pigments, and pharmaceuticals. Utilizing dynamic crossflow technology, this unit excels in concentrating and clarifying high-viscosity suspensions, achieving up to 80 wt.-% concentration levels. Its modular design supports both continuous and batch operations, allowing for high throughput and versatile application. The unique dynamic shear gap principle ensures optimal separation while maintaining flowability even at high concentrations. Operating at pressures up to 6 bar and temperatures up to 100°C, it supports various filter media, including micro and ultrafiltration membranes. The BoCross Dynamic is fully automated, integrates seamlessly into existing production lines, and offers energy efficiency through advanced motor control. Suitable for handling complex materials, it features a hermetically sealed system, ensuring no air contact during processing, making it ideal for sensitive products.

Benefits

- Enhances production efficiency by processing high-viscosity suspensions in a single pass.

- Minimizes operational costs with automated, continuous operation.

- Adapts to diverse material properties, ensuring consistent results across different products.

- Protects product integrity with a hermetic design that prevents contamination.

- Optimizes energy use through advanced dynamic crossflow technology.

- Applications

- Titanium dioxide, Pharmaceutical intermediates, Pharmaceutical iron hydroxide, Minerals, Chemical and pharmaceutical sector, Fillers and dyes, Pigments, Plastic intermediates, Calcium carbonate

- End products

- Ibuprofen tablets, Polycarbonate resin, Titanium white pigment, Calcium carbonate filler for paints, Paint pigment dispersion, Polyacetals, Polymer additives, Pharmaceutical grade iron hydroxide, Polyethylene terephthalate (pet) pellets, Titanium dioxide pigment, Phosphate buffer solutions, Iron oxide pigment, Carbon black, Calcium carbonate powder

- Steps before

- Suspension Preparation, Mixing, Reaction, Neutralization, Pre-concentration

- Steps after

- Drying, Solid Separation, Crystallization, Precipitation, Further Processing

- Input ingredients

- microfine suspensions, nanoscale suspensions, microfine to nanoscale suspensions with high concentrations, high viscosity suspensions, slimy particles, gel-like particles

- Output ingredients

- clear filtrate, concentrated suspensions, particle-free filtrate, solid separation, pasty, spreadable solids, washed solids

- Market info

- BOKELA is known for its expertise in engineering and manufacturing filtration technology and equipment, particularly for solid-liquid separation processes in various industries, offering innovative, high-performance solutions with a strong reputation for reliability and efficiency.

- Filter Area

- 0.1–8 m²

- Operating Pressure

- up to 6 bar

- Operating Temperature

- up to 100°C

- Concentration Level

- up to 80 wt.-%

- Viscosity

- up to 25, 000 mPas

- Suspension Particle Size

- 0.01–200 μm

- Drive Power

- 3–< 55 kW

- Automatic Operation

- Yes

- Batch vs. Continuous

- Continuous or Batch

- Filter Type

- XS, S, M, L

- Number of Modules

- 5–20

- Working mechanism

- Dynamic crossflow filtration

- Batch vs. continuous operation

- Continuous or Batch

- Automation level

- Fully automatic

- Energy efficiency

- High throughput with low energy usage

- Cleaning method

- Hermetically sealed system, no air contact

- Process adaptability

- Flexible to changes in feed characteristics

- Integrated steps

- Thickening, washing, clarifying

- Suspendable solids concentration

- Up to 80 wt.-%

- Abrasion resistance

- High

- Biological compatibility

- Suitable for pharmaceutical intermediates

- Cleanability

- CIP/SIP compatible

- Corrosive resistance (e.g. acids)

- Resistant to various chemicals

- Density/particle size

- 0.01–200 μm

- Filter Module Size

- 0.1 m² to 8 m²

- Modular Construction

- Disc-shaped filter modules

- Hermetic Sealing

- Closed system process chambers

- Temperature Range

- Up to 100 °C

- Operating Pressure

- Up to 6 bar (a)

- Fluid Discharge Method

- Controlled discharge via exhaust valve

- Filter Diameter

- 145 mm to 555 mm

- Drive Power

- 3 kW to < 55 kW

- Filter Area

- 0.1 m² to 8 m²

- Modular Construction

- Yes

- Operating Pressure

- Up to 6 bar (a)

- Operating Temperature

- Up to 100 °C

- Hermetic Process

- Yes

- Filter Media Types

- Micro filtration membranes, Ultrafiltration membranes, Sintered plastic, Ceramic membranes, Sieve composite sheets, Metallic media

- Automation Level

- Fully Automatic