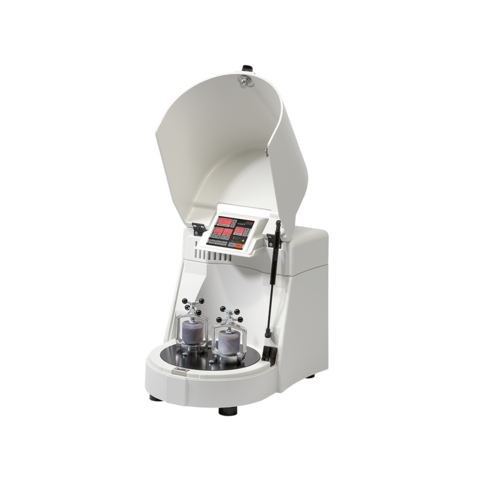

Planetary micro mill for fine comminution

Achieve unparalleled precision in micron-level materials processing with this compact yet powerful planetary mill, perfect for reducing samples to colloidal fineness and ideal for laboratory environments demanding uniformity and versatility in sample preparation.

Achieves Fine Grinding and Homogenization

The Planetary Micro Mill PULVERISETTE 7 Classic Line from FRITSCH offers a solution for laboratories requiring precise control in sample comminution. This mill utilizes the planetary principle, ensuring efficient and uniform grinding of small samples to colloidal fineness. With a rotation speed up to 800 rpm, it excels in applications such as geology, chemistry, and pharmaceuticals, producing end-products like colloidal suspensions and nano-particles. The mill can handle a capacity of up to 2 x 20 ml per batch, supporting various processes such as mixing and homogenizing. Its fully encapsulated grinding chamber features an ergonomic IP64 membrane keyboard and a maintenance-free drive, enhancing operational efficiency. Available in various materials to prevent sample contamination, the PULVERISETTE 7 Classic Line is engineered for continuous operation with features like programmable cycles, energy-saving modes, and cooling fans for long grinding sessions. The unit supports seamless integration into lab workflows, providing reproducible results with minimal bench space.

Benefits

- Ensures precise and reproducible grinding results for accurate analyses.

- Minimizes lab space requirements, optimizing bench-top efficiency.

- Reduces operational costs with energy-saving modes and maintenance-free design.

- Offers customizable grinding materials to prevent sample contamination.

- Enables prolonged operation with integrated cooling and programmable cycles.

- Applications

- Geology and mineralogy, Ceramics, Chemistry, Metallurgy, Biology, Material technology, Minerals, Mechanochemistry, Pharmaceuticals

- End products

- Nano-particles from mineral samples, Cyclic boronic acid ester, White aluminum oxide, Red pigment mixtures, Suzuki-miyaura reaction products, Knoevenagel condensation products, Hair samples for drug testing, Potassium manganite oxidation products, Colloidal suspensions, Agate samples

- Steps before

- Pre-crushing, Sample Selection, Weighing, Drying, Mixing

- Steps after

- Particle Sizing, Sample Analysis, Packing, Coating, Purification

- Input ingredients

- hard materials, medium-hard materials, brittle samples, moist samples, coarse materials, agate sample, emulsions, pastes, white aluminum oxide, red pigments, Molinia Caerulea, hair samples, geo-samples, ceramics samples, chemical compounds

- Output ingredients

- fine comminution, colloidal fineness, uniformly fine particles, reduced particle size, comminuted agate sample, homogenized emulsions, homogenized pastes, nano-particles, fine chemical synthesis, organic compounds

- Market info

- Fritsch is renowned for manufacturing high-quality, engineered-to-order laboratory instruments for sample preparation and particle sizing in research and industrial laboratories, with a strong reputation for precision, innovation, and reliability.

- Rotational speed

- Up to 800 rpm

- Capacity

- 2 x 20 ml

- Working stations

- 2

- Comminution fineness

- Below 1 μm

- Grinding bowl sizes

- 12 ml or 45 ml

- Transmission ratio

- 1

- Centrifugal acceleration

- Up to 50 g

- Programmable grinding cycles

- Up to 99 repetitions

- Electricity-saving mode

- Yes

- Working mechanism

- Planetary Principle

- Rotational speed

- Up to 800 rpm

- Automation level

- Programmable microprocessor control

- Batch vs. continuous operation

- Batch

- Cooling method

- Built-in fan

- Simultaneous processing

- 2 samples

- Centrifugal acceleration

- Up to 50 g

- Reverse function

- Yes

- Energy-save function

- Electricity-saving mode

- Reproducible grinding results

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Capable for emulsions and pastes

- Compact footprint

- Small footprint

- Discharge method

- Manual or automated

- Control panel type

- Ergonomic IP64 membrane keyboard

- Cooling feature

- Built-in fan for cooling

- Working stations

- 2 stations

- Grinding bowl sizes

- 12 ml or 45 ml

- Grinding chamber encapsulation

- Complete encapsulation

- Centrifugal acceleration

- Up to 50 g

- Rotational speed

- Up to 800 rpm

- Sample capacity

- Up to 2 x 20 ml

- Control panel type

- Ergonomic IP64 membrane keyboard

- Integration possibilities

- Programmable microprocessor control

- Cooling option

- Built-in fan

- Grinding bowl material options

- 7 different materials

- Grinding bowl sizes

- 12 ml or 45 ml