Hammer mill for grinding dry or low-moisture grains

Efficiently transform dry grains into high-quality feed and flour with precision grinding and crushing, ensuring optimal particle size distribution for enhanced nutritional benefits and improved processing efficiency.

Grinds and Mills Grains for Feed Production

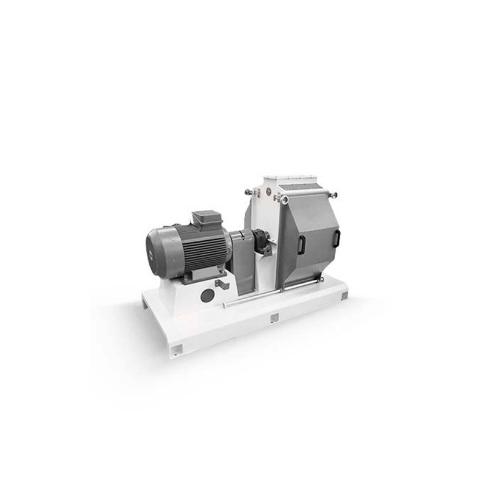

The ÇEKİÇLİ DEĞİRMEN from Uğur Promilling is a robust hammer mill designed for efficient grinding and milling of grains and agricultural products. This equipment stands out for its durable steel construction and a design that allows quick sieve changes without halting operations, enhancing production flow for feed producers and milling companies.

The hammer mill processes dry and slightly moistened grains into products like poultry feed and whole wheat flour, with precision grinding for consistent particle sizes. It features a powerful motor directly coupled to the rotor, optimizing energy use and continuous operation in pre-processing and processing departments.

Engineered with hardened steel hammers, it ensures longevity and efficient crushing performance. The flexibility of operation allows integration into existing lines, accommodating various feed types and agriculture products. Available in different material options to resist wear and corrosion, it meets industry standards for food production environments. Additionally, Uğur Promilling offers customization and engineering support to adapt the mill to specific production needs, ensuring optimal performance and reliability for end-users.

Benefits

- Ensures consistent feed quality with precise grinding.

- Minimizes production interruptions with easy, rotor-safe sieve changes.

- Reduces energy costs via efficient motor coupling.

- Offers durability and long service life with hardened steel components.

- Integrates seamlessly into existing milling and feed production lines.

- Applications

- Grains, Animal feed, Agricultural products, Dry ingredients, Milling products

- End products

- Dehydrated alfalfa, Barley malt, Oat bran, Whole wheat flour, Swine feed, Cornmeal, Ground barley, Poultry feed, Beef cattle feed, Soybean meal

- Steps before

- Cleaning, Dampening

- Steps after

- Blending, Packing

- Input ingredients

- taneli kuru maddeler, az rutubetli maddeler

- Output ingredients

- öğütülmüş ürün

- Market info

- Construction

- Steel Construction

- Hammer Material

- Hardened Steel

- Motor Connection

- Direct Coupling

- Design Feature

- Rotor Exchange Without Stopping

- Application

- Grinding of Dry or Slightly Humid Raw Materials

- Flexibility

- Easy and Quick Screen Change

- Mounting

- Motor and Mill Body on Common Chassis

- Grinding Mechanism

- Hammer Mill

- Component Design

- Free-moving hammers

- Screen Changeability

- Quick, easy without stopping rotor

- Motor Coupling

- Directly coupled

- Operation Type

- Continuous

- Abrasion resistance

- High

- Biological compatibility

- Not applicable

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Moderate

- Density/particle size

- Suitable for dry or low-moisture grains

- Material

- Hardened steel/Steel construction

- Design

- Rotating hammers on a strong shaft

- Ease of Modification

- Quick change of sieve without stopping rotor

- Mounting

- Motor and body mounted on common chassis

- Hammer Material

- Hardened Steel

- Screen Changeability

- Quick-change without stopping rotor

- Motor Coupling

- Directly coupled

- Design Type

- Steel construction and welded