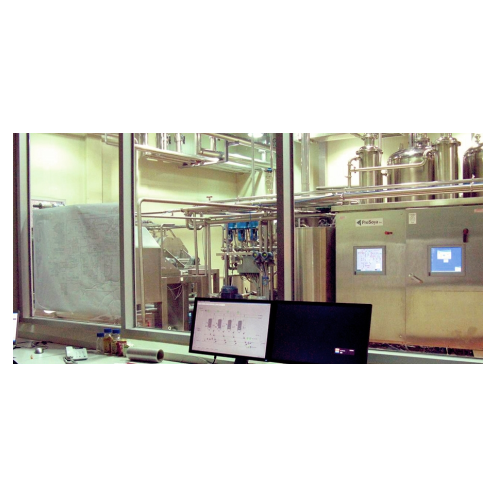

Oat milk processing plant

Transform whole oats into creamy, nutritious oat milk with precision, leveraging advanced continuous processing to enhance efficiency and product quality.

Processes and Packages Oat Milk Efficiently

The Industrial Oat Milk Processing Plant from ProSoya Inc. offers a seamless solution for plant-based milk manufacturers aiming to optimize production and quality. This plant excels in integrating key processes—milling, enzyming, separation, sterilization, and packaging—within a continuous, high-speed operation framework. Designed for the production of oat, rice, chia, and quinoa milk, it caters to the growing demand for dairy alternatives in the food and beverage industry. The system handles significant volumes, ensuring throughput efficiency tailored to specific production scales.

Automated through a PLC-controlled system, the plant facilitates remote monitoring, enhancing operational control. Its energy-efficient design reduces consumption by 30% through optimized motor systems, resulting in cost savings. Constructed from high-grade stainless steel, it offers exceptional corrosion resistance and durability. The plant meets industry standards and certifications, assuring compliance within food processing regulations. With an integrated CIP system, it streamlines cleaning processes, ensuring hygiene and reducing downtime. ProSoya Inc. provides comprehensive engineering support, offering customization options to meet unique production requirements, ensuring that each plant is perfectly aligned with customer needs.

Benefits

- Increases production efficiency with a continuous high-speed process.

- Lowers operational costs through 30% reduced energy consumption.

- Ensures regulatory compliance with food industry standards.

- Simplifies maintenance with integrated CIP system.

- Customizable design tailored to specific production needs.

- Applications

- Dairy alternatives, Plant-based milk, Nutritional beverages

- End products

- Rice milk, Quinoa milk, Oat milk, Chia milk

- Steps before

- Milling, Enzyming, Bran Separation

- Steps after

- Flavoring, Sterilization, Packaging

- Input ingredients

- oats, enzymes, water, flavourings, vitamins

- Output ingredients

- oat milk, loose fibres, bran

- Market info

- Prosoya is known for its expertise in manufacturing soy milk production equipment, providing innovative solutions for efficiently processing soybeans into soy milk and related products, highly regarded for its advanced technology and customizable engineering solutions.

- Milk Type

- Oat

- Production Process

- Milling, Enzyming, Bran Separation, Sterilization

- Additional Ingredients

- Vitamins, Flavourings

- Shelf Life

- Not specified

- Calcium Content

- 36% of daily recommended intake

- Vitamin Content

- Vitamin A, Iron

- Equipment Use

- Similar to rice, chia, quinoa milk production

- Sterilization

- Yes

- Package Type

- Not specified

- Process Type

- Batch or Inline

- Milling Process

- Wet/Dry Milling

- Enzyming Steps

- Alpha-Amylase / Protease Addition

- Sterilization Method

- Pasteurization / UHT

- Automation level

- Manual / PLC / SCADA

- Fiber Separation Process

- Centrifugal / Filtration

- Packaging Type

- Tetra Pak / Bottle

- Flavoring Addition

- Inline / Batch

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Feed method

- Milling, Enzyming

- Discharge method

- Sterilization, Packaging

- Control panel type

- Touchscreen / PLC

- Integration possibilities

- Compatible with rice, chia, and quinoa milk processing

- Custom ingredient addition

- Vitamins / Flavorings

- Scalability

- Small to large production scales