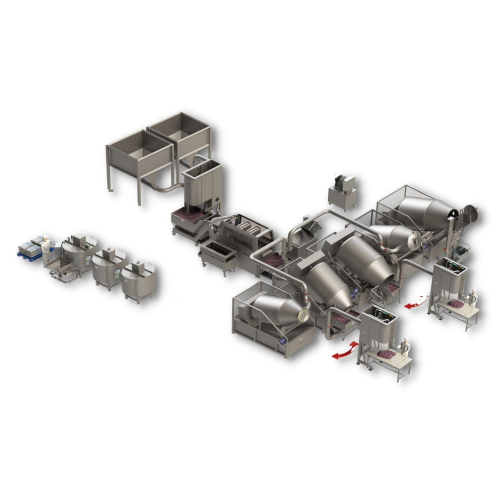

Fully automated meat processing line

Optimize your meat production with a seamlessly integrated line that boosts productivity, enhances product quality, and extends shelf life through advanced automation and precise control systems.

Enhances Quality and Streamlines Meat Processing

GAROS offers a comprehensive solution with its Fully Automated Lines specifically designed for meat and poultry processing, targeting efficiency and quality improvement. These lines integrate Garos’ equipment including injectors, tumblers, and brine preparation systems, to create a seamless and continuous operation. The lines are designed to automate processes that traditionally require significant manual effort, thereby reducing labor costs and enhancing productivity. Ideal for producing an array of end-products such as sliced ham, sausages, and deli meats, the lines are engineered for high-speed and continuous processing, supporting significant throughput.

Utilizing robust automation and integration, these processing lines ensure improved microbiological quality, extending product shelf life. The lines incorporate advanced control systems for precise process management, allowing easy integration with existing plant systems. Available in corrosion-resistant materials suitable for the food industry, the lines comply with industry standards for hygiene and efficiency. Moreover, options for customization are available to fit specific production needs, backed by engineering support for seamless installation and maintenance operations.

Benefits

- Increases production efficiency by automating manual tasks and reducing labor costs.

- Enhances product shelf life with improved control over microbiological quality.

- Supports seamless integration into existing production lines for uninterrupted operation.

- Minimizes cleaning and maintenance time with efficient design.

- Offers flexibility for a wide range of meat and poultry end-products, enhancing product variety.

- Applications

- Meat products, Sausage production, Food processing, Poultry, Deli meats, Processed meats

- End products

- Chicken breast fillets, Beef jerky, Pepperoni, Pre-cooked sausages, Smoked brisket, Corned beef, Bologna, Luncheon meat, Turkey slices, Chorizo, Kielbasa, Hot dogs, Salami, Sliced ham

- Steps before

- Grinding, Brine Preparation, Injecting

- Steps after

- Packing, Sterilization, Quality Control

- Input ingredients

- Output ingredients

- Market info

- GAROS is known for manufacturing high-quality engineered-to-order industrial equipment, specializing in food processing machinery with a strong reputation for reliability and innovation in the market.

- Automation

- Fully Automated

- Productivity Improvement

- Increased Yields

- Microbiological Quality Improvement

- Enhanced Shelf Life

- Human Labor Reduction

- Significant Reduction

- Production Flow

- Continuous

- Automation level

- Fully Automated

- Batch vs. continuous operation

- Continuous

- Integration capability

- Complete production line

- Staff reduction

- Significant reduction

- Production flow

- Continuous

- Process Suitability

- Meat processing

- Equipment Versatility

- Can include various types of Garos equipment

- Machine footprint

- Dependent on configuration

- Integration capability

- Single to complete production line

- Discharge method

- Automated

- Control panel type

- Automated/PLC

- Integration possibilities

- Complete integration into a single production line

- Control panel type

- Automated control panel

- Automation level

- Fully automated production line

- Product customization

- Adaptability to specific production needs