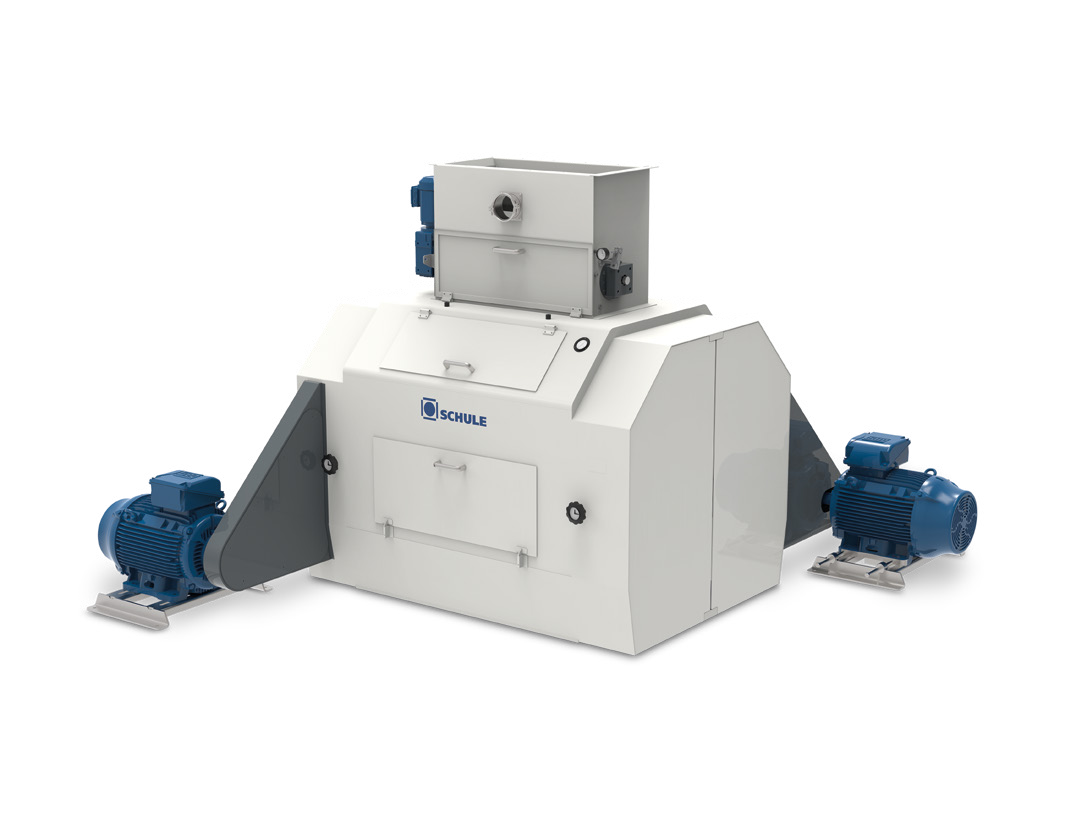

Flaking roller mill for oats

Consistent flake size is one of the main contributors to processed oat quality. But producing a homogeneous shape and thickness in a continuous system requires accurate milling with minimal downtime.

Flake kernel in a consistent shape

The flaking roller mill from Schuler flakes pre-treated oats into homogenous sizes. The roller integrates into other systems like a steamer or tempering bin to facilitate a continuous process. Meanwhile, the system can adjust to different thickness levels during production.

The mill is fitted with special bearings and shock absorbers that ensure vibration-free operation. And, thanks to the hydraulically adjustable scrapers, the roller mill eases the cleaning process and the general upkeep of the machine.

Benefits

- Vibration-free rolling

- Automatic roller gap adjustment

- Durable design