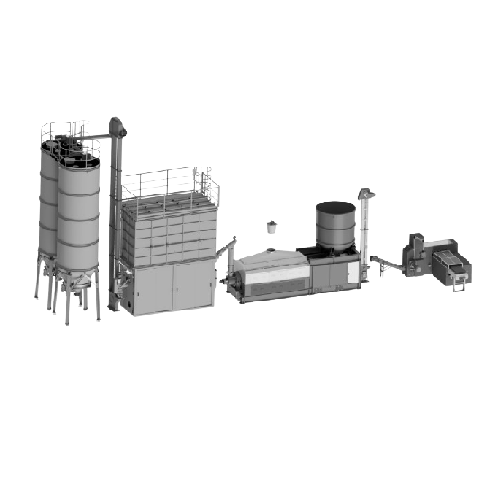

Lead oxide mill for battery production

Optimize your lead-acid battery production with chainless technology, ensuring consistent lead and oxide powders while reducing maintenance demands and increasing operational efficiency.

Produces Lead and Oxide Powders for Batteries

The Chainless Lead Oxide Mill from Sovema Group is engineered for high-efficiency lead powder production, critical for the battery manufacturing and chemical processing industries. This mill operates without traditional chains, reducing contamination and maintenance. It specializes in producing uniform lead and oxide powders used in lead-acid batteries. With its robust design, the mill seamlessly integrates into existing production lines, offering scalability and reliability. It maximizes production consistency while minimizing energy consumption, thanks to precision-engineered components. The equipment’s corrosion-resistant materials ensure longevity and compatibility with various industrial conditions, making it a vital asset for enhancing production quality and efficiency.

Benefits

- Enhances production efficiency with consistent lead powder output.

- Reduces operational maintenance due to chainless design.

- Lowers energy consumption through optimized motor performance.

- Seamlessly integrates with existing production lines.

- Ensures product consistency and quality for battery manufacturing.

- Applications

- Batteries, Metal powders

- End products

- Lead-acid batteries, Lead powder, Oxide powder

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Sovema Group is known for its expertise in manufacturing advanced equipment for lead-acid battery production, offering turnkey solutions and innovative technology to enhance battery manufacturing efficiency and quality.

- Working mechanism

- Chainless

- Automation level

- Automatic / PLC-controlled

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual / CIP

- Energy efficiency

- Optimized for low kWh/kg

- Changeover time

- Quick setup

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Process type

- Chainless