Industrial grinding solution for hard and abrasive materials

Efficiently grind and mill a spectrum of materials from coarse raw minerals to fine powders, ensuring uniform particle size and enhanced product quality across your continuous operation.

Grinds and Mills Varied Industrial Materials

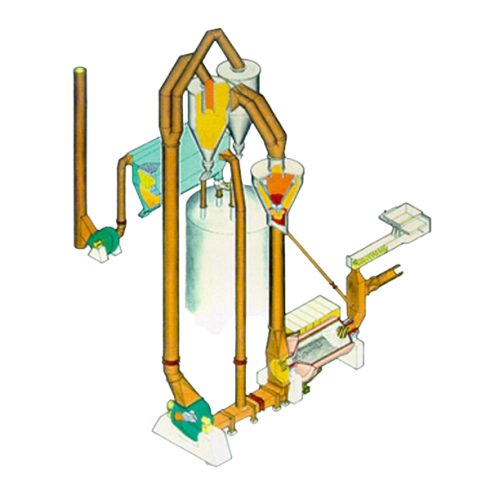

The Raymond Ball Mill from Schenck Process is designed to meet complex material preparation needs in industries such as mineral processing, cement plants, and power generation. Known for its rugged design and ease of maintenance, this horizontal mill efficiently grinds hard and abrasive materials like coals, ores, and slags to precise specifications. Utilizing a slow-speed operation, it ensures uniform particle size distribution, vital for high-quality end-products like clinker cement and lithium-ion battery powders. With a processing capacity of up to 15ft/4.6m in diameter and 24ft/7.3m in length, it supports continuous or manual operations. Integration is seamless with PLC controls and optional remote monitoring, optimizing energy usage and offering consistent throughput. To ensure durability and chemical compatibility, it is available in various materials, and its design allows easy access for maintenance and cleaning, minimizing downtimes. Fully customizable, the mill can be engineered to fit specific processing requirements with tailored rotor speeds and chamber configurations.

Benefits

- Enhances material uniformity with precise particle size control for superior product quality.

- Minimizes operational costs through energy-efficient motor optimization.

- Reduces maintenance downtime with easy-access design and robust construction.

- Provides versatile processing options with customizable configurations for diverse applications.

- Facilitates seamless integration and monitoring with PLC controls for improved operational efficiency.

- Applications

- Abrasives, Copper ore, Minerals, Catalysts, Bauxite, Slag, Cement, Raw meal, Agrichemicals, Petcoke, Clinker, Batteries, Power generation, Limestone, Coals, Fertilizers, Iron ore, Coating materials, Phosphate

- End products

- Copper wire, Iron pellets, Smelter feed stock, Grinding wheels, Clinker cement, Herbicides, Active pharmaceutical ingredients (apis), Electrical steel coatings, Polypropylene films, Ceramic tiles, Nitrogen-based fertilizers, Anodes for aluminum production, Lithium-ion battery powders, Metallurgical grade coke, Concrete additives, Automotive catalysts, Paint pigments, Agricultural lime

- Steps before

- Crushing, Screening, Material Handling, Preliminary Milling

- Steps after

- Separation, Filtration, Air Classification, Product Packaging

- Input ingredients

- Petcoke, Bituminous Coal, Anthracite Coals, Phosphate, Abrasives, Slag, Limestone, Bauxite, Iron Ore, Copper Ore, Raw Meal, Clinker

- Output ingredients

- Ground Petcoke, Ground Bituminous Coal, Ground Anthracite Coals, Fine Phosphate, Ground Abrasives, Fine Slag, Fine Limestone, Processed Bauxite, Processed Iron Ore, Processed Copper Ore, Ground Raw Meal, Fine Clinker

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Mill Type

- Raymond Ball Mill / Tube Mill

- Diameter

- Up to 15ft / 4.6m

- Length

- Up to 24ft / 7.3m

- Application

- Grinding of hard, abrasive materials

- Material Processed

- Petcoke, Bituminous, Anthracite Coals, Phosphate, Abrasives, Slag, Limestone, Bauxite, Iron Ore, Copper Ore, Raw Meal, Clinker

- Wear Life

- Excellent

- Availability

- High

- Maintenance Ease

- Easy

- Operating Speed

- Slow

- Grinding Mechanism

- Horizontal slow speed

- Material Handling Compatibility

- Hard, abrasive materials

- Operational Ease

- Easy maintenance

- Wear Life

- Excellent

- Size Capacity

- Up to 15ft/4.6m diameter, 24ft/7.3m length

- Automation Level

- Manual / PLC

- Cooling Method

- Natural air cooling

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Processed Materials

- Petcoke, Bituminous coal, Anthracite, Phosphate, Abrasives, Slag, Limestone, Bauxite, Iron Ore, Copper Ore, Raw Meal, Clinker

- Applicable industries

- Mineral Processing, Cement, Power Generation

- Machine footprint

- Available in sizes up to 15ft / 4.6m diameter and 24ft / 7.3m length

- Tubular shape

- Ball Mill / Tube Mill

- Rugged design

- Yes

- Discharge method

- Not specified

- Control panel type

- Digital / Touchscreen

- Integration possibilities

- SCADA / PLC

- Customization options

- Size up to 15ft / 4.6m diameter

- Customization options

- Length up to 24ft / 7.3m

- Discharge method

- Customizable