Powder Milling Equipment

Find milling technology for powder products and connect with a global network of leading machine manufacturers.

The journey from raw materials to powders typically involves subsequent milling stages. Solids are crushed, shredded, and milled into smaller materials. Advanced powder milling equipment pulverizes granules into powders of varying grades, from coarse to ultrafine. Powder fineness determines the surface area ratio of particles. Increasing this ratio accentuates the properties of the material required in products such as high-potency APIs. But extreme fineness is not always desirable. For example, sawdust particles that go into wood pellets must retain a level of coarseness to prevent smoke when lit up.

Which powder milling technology do you need?

Conical mill for high-capacity powder milling

Optimize your powder milling process with efficient conical milling systems ...

Industrial sugar powder mill

Achieve precise sugar granulation with a high-speed mill designed for continuous production, en...

Air classifier mill for ultra-fine powder grinding

Optimize your milling operations with precision particle size control ...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

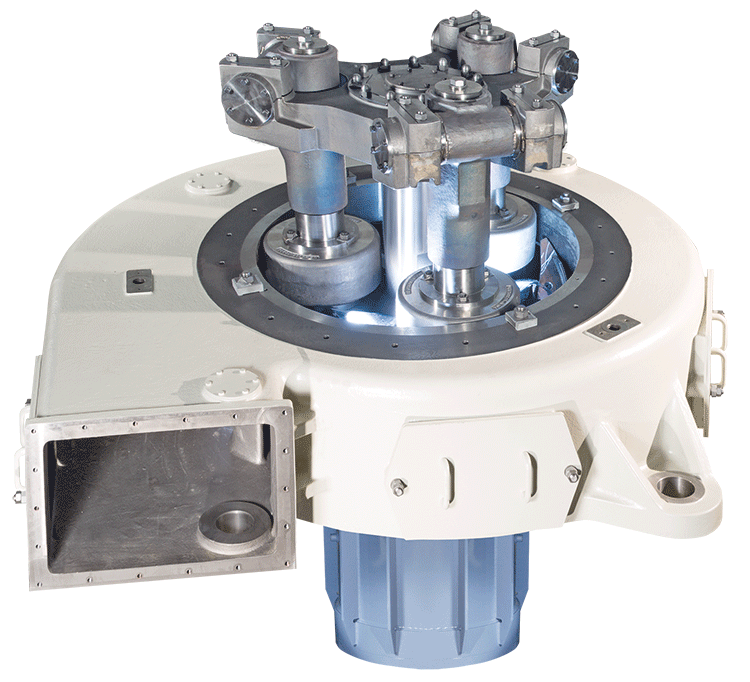

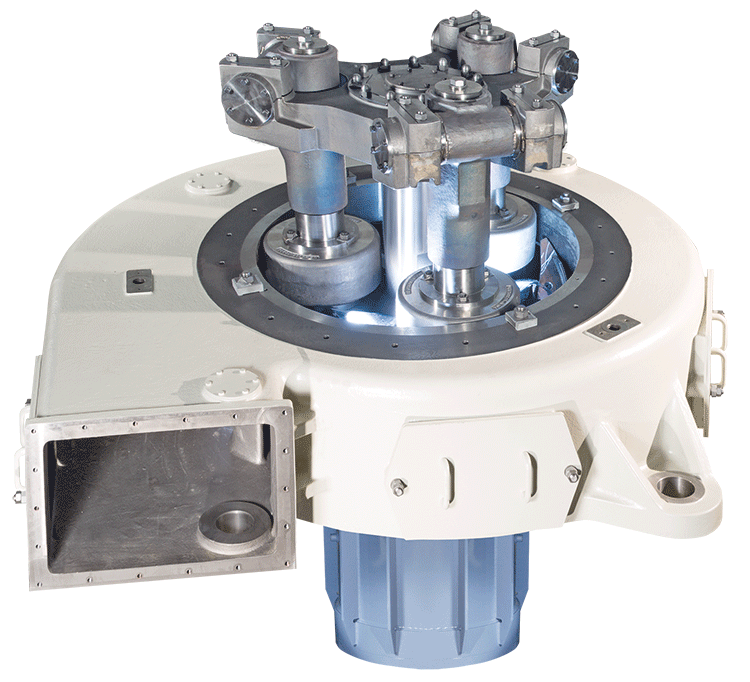

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

Laboratory conical screen mill for powder calibration

Achieve precise particle size control with this compact laboratory ...

Conical screen mills for powder calibrating

Achieve precise particle size distribution for your powders and granules with ...

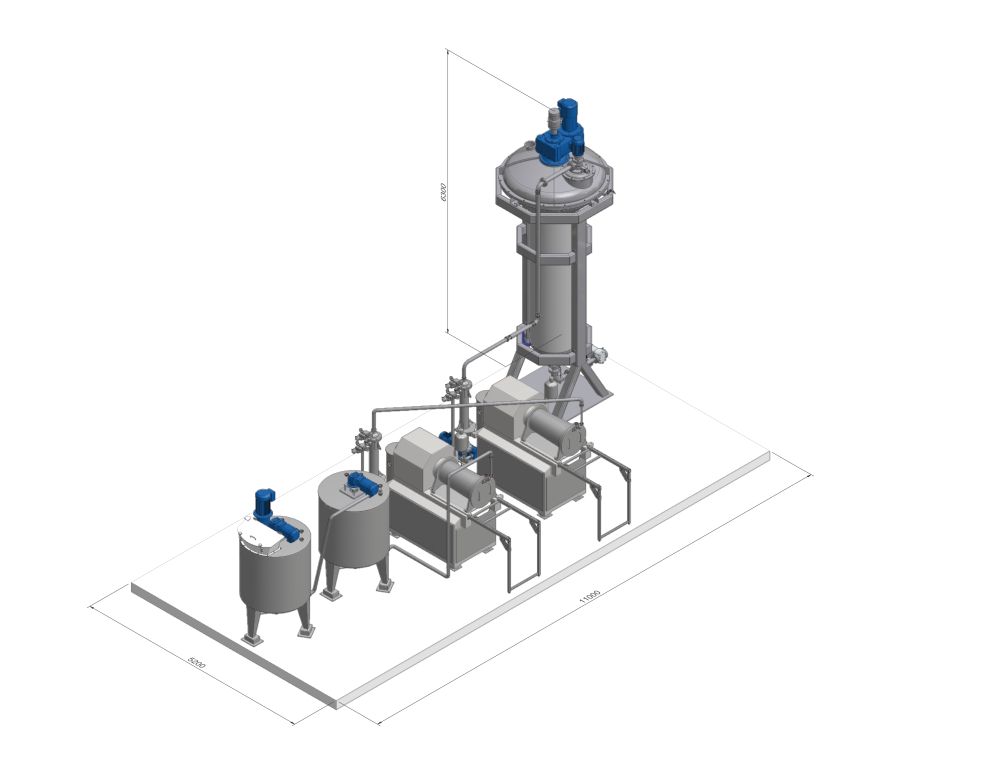

Milling flash dryer for fine powder processing

Achieve precise moisture control and prevent agglomeration in your processi...

High containment powder transfer valve

Ensure high containment for potent powders in your production line, reducing contami...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

Dry granulation system for pharmaceutical powders

Streamline your powder processing with a dry granulation system that en...

Material handling system for granules and powders

Optimize your production with seamless material handling specifically d...

Laboratory scale powder/liquid mixer

Easily integrate powders into complex liquid formulations at a laboratory scale, ensur...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Blending tank for cosmetic powders

The production of high-quality cosmetics powders requires perfect mixing and dispersal o...

Production-scale milling and screening system

Achieve precise particle size distribution and high throughput rates with a ...

Mid-size milling platform for pilot-scale production

Achieve precise particle size control with this integrated milling s...

Universal mill for fine grinding in food and pharma industries

Achieve unparalleled particle size reduction with high-pe...

Cone mill for particle size reduction in pharmaceuticals

Achieve precise particle size control with this cone mill, desig...

Spiral jet mill for ultrafine micronisation

Optimize your powder processing with precision-driven micronisation that ensur...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

Jet mill for toner and pigment industries

Optimize particle size and distribution for high-demand applications with this h...

High pressure roller mill for medium-fine crushing

Achieve precision in particle size with high-pressure roller mills, id...

Particle sizing solution for milling and sifting

Streamline your milling and sifting processes with a flexible system desi...

Pre-breaker for initial material size reduction

Efficiently prepare your bulk materials for further processing by swiftly ...

Conical mill for particle size reduction

Achieve precise particle size control and reduce thermal stress on materials with ...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

High capacity production milling for bulk materials

Optimize your production with our high-capacity milling solution, des...

Conical mill for particle size reduction and homogenization

Achieve precise particle size reduction and homogenization w...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

Modular big bag discharge station for bulk material handling

Streamline your bulk material handling with a customizable ...

Hygienic feeding hopper for bulk solids

Ensure optimal hygiene in your powder and granular processing with a feeder that fa...

Pharmaceutical roller compactor

Achieve consistent granulate quality with optimized compacting processes, ideal for transfor...

Industrial roller mill for high-stability milling

Optimize your milling process with a high-speed roller system designed ...

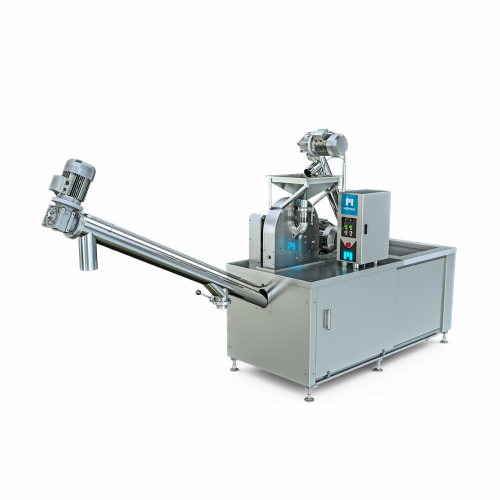

Lab scale roller compactor for dry granulation

Achieve seamless scale-up from lab development to full-scale production wit...

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Industrial blender for uniform mixing

Optimize your process with precise mixing and consistent blending, ensuring uniformit...

Pilot scale batch mixer for small scale production

Achieve precise control and consistency in small-scale production with...

Bottom entry mixers for high viscosity products

Optimize your production line with mixers designed to handle both high and...

Particle size reduction air conveying system

Achieve precise particle size reduction and contamination-free processing for...

Production scale jet mill

Large volume manufacturers demand the most out of their production process, including powder milli...

Jet mill micronizer

Small scale manufacturers that require effective micronization of powders for their process lines may nee...

Pilot scale jet mill

In a pilot scale level or preliminary study, all the production process steps have to satisfy the small ...

Laboratory jet mill

Manufacturing small quantities of high-value products requires efficient machines that can process these ...

Jet mill for clinical trials

R&D laboratories may need to reduce the size of powder particles in small quantities for cl...

Roll mill for coffee beans

When you want flexibility to grin beans for filter coffee to Turkish coffee at particle sizes ran...

Vertical ball mills for chocolate refining

Powders of extremely high fineness can easily be produced with ball mills and a...

Grinding and drying of CaCO3

Widely used in the construction industry as filling materials, calcium carbonate is usually mad...

Grinding and drying of bentonite

After crushing and drying mined bentonite, this clay mineral is usually processed through a...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Horizontal ball mill for chocolate refining

Powders of extremely high fineness can be produced with ball mills and agitate...

Mixer and refiner for chocolate compound

Mix cocoa liquor, cocoa powder, sugar, and lecithin in a small scale and refine sm...

Batch chocolate machine with vertical ball mill

To mix and refine cocoa liquor, cocoa powder, sugar, and lecithin, several...

Continuous chocolate line with horizontal ball mills

For mixing and refining cocoa liquor, cocoa powder, sugar, and lecit...

Batch chocolate line with horizontal ball mill

To mix and refine cocoa liquor, cocoa powder, sugar, and lecithin, several ...

Automatic rework system for biscuit and bread scrap

Scraps are an inevitable byproduct of biscuit and bread production. W...

Cheese grater

Breaking down large blocks into grated, shredded, powdered or planed cheese requires multiple graded discs that ...

Small scale nut chopping machine

Many confectionery and bakery products use nuts as a key ingredient or decoration. The abil...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Horizontal rotary ball mill drum

A horizontal rotary ball mill drum can be used for grinding of dry hard materials, such as ...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Conical mill for drug formulation

The efficient size reduction of granular powders is a key step in many pharmaceutical pro...

Airshocking hammer

Silos, hoppers, bins, and other containers can build up a layer of powdered product on the internal walls....

Industrial nut grater

Pressure from the grinding process can cause damage to food products as well as induce unwanted heating...

Nut dicer

Dicing nuts can generate a large volume of wasteful and messy powdered nut residue.

Versatile fine impact mill for soft materials

Achieve precision grinding with flexibility for a wide range of materials, e...

Over-driven conical mills for precise particle size reduction

Achieve consistent particle size reduction with minimal he...

Laboratory and pilot plant horizontal bead mill

Achieve precision milling with minimal product waste, ensuring consistent ...

Particle analysation monitor

Products like granules, tablets and capsules require inspection at numerous steps in the produc...

Corundum disk mill

Wet milling and grinding of viscous liquids or pastes containing solid particles such as peanut butter,mus...

Cone mill machine

When your raw materials include agglomorated suspensions of grainy or crystalline solids and your process n...

Reclaim crusher

Waste products and rejected materials are inevitably generated from any gypsum products manufacturing process....