Industrial mixer for high moisture content products

Optimize the texture and consistency of high-moisture foods with precision milling, ensuring seamless integration into your continuous production line while reducing downtime for cleaning and maintenance.

Mills and Reduces High-Moisture Food Products

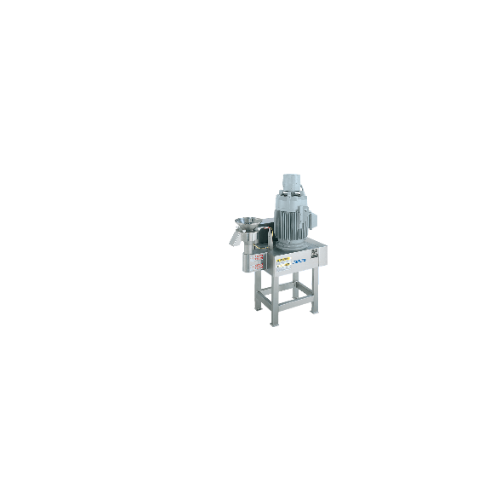

The Comitrol Processor Model 3000 from Urschel Laboratories is a high-speed milling machine specifically tailored for processing high-moisture food products such as vegetables, cooked meats, and seafood mixtures. Utilizing a powerful motor of up to 40 HP, it operates continuously for maximum throughput, making it ideal for integration into demanding production environments. The machine’s specially designed impellers and 6-inch cutting heads ensure precise reductions, producing end-products like ground beef for sausage, tofu spread, and creamed corn. Its stainless steel construction offers robustness and sanitation, while the two-piece enclosure simplifies cleaning and maintenance, minimizing downtime. Designed with user adaptability in mind, the Model 3000 supports easy disassembly for care of its cutting parts, ensuring long-term operational reliability in food, dairy, meat, vegetable, seafood, and bakery industries.

Benefits

- Ensures consistent product texture with precision-cutting capabilities.

- Minimizes downtime with continuous operation and easy maintenance.

- Enhances sanitation with durable stainless steel construction.

- Reduces labor costs through simplified cleaning and disassembly.

- Accommodates diverse processing needs with customizable impeller selections.

- Applications

- Soybean granule, Cooked meats, Soybean paste, Bean paste, Beef tissue, Seafood mixture, Vegetables, Corn kernel, Ricotta cheese

- End products

- Seafood paté, Textured soy protein, Cornmeal, Refried beans, Creamed corn, Cheese spread, Tofu spread, Ground beef for sausage, Gelatin products

- Steps before

- Input Preparation, Chopping, Pre-cooking, Sizing

- Steps after

- Packaging, Storage, Transportation, Further Processing

- Input ingredients

- whole kernel sweet corn, cooked meats, vegetables, squid/fish mixture, soybean paste, soybean granule, corn kernel, bean paste, beef tissue, ricotta cheese

- Output ingredients

- coarse reductions, fine reductions

- Market info

- Urschel is known for its expertise in precision cutting technology and manufacturing industrial food processing equipment, especially cutting machines. It has a strong reputation for quality and innovation in delivering engineered-to-order solutions for the food processing industry.

- Motor Power

- 15, 30, or 40 HP (11.2, 22.4, or 30 kW)

- Input Size

- Maximum 2-1/2" (63.5 mm) in any dimension

- Length

- 51.69" (1313 mm)

- Width

- 32.92" (836 mm)

- Height

- 71.75" (1822 mm) with 40 HP motor

- Net Weight

- 1100 lb (499 kg)

- Cuts

- Coarse to fine reductions

- Cutting Head Diameter

- 6" (152.4 mm)

- Material

- Stainless steel construction

- Working mechanism

- Impeller with vertical knives

- Flow type

- Continuous

- Disassembly process

- Simplified for easy cleaning

- Automation level

- Manual / Automated operation

- Cleaning method

- Manual

- Material processed

- High moisture content products

- Abrasion resistance

- Yes

- Biological compatibility

- Suitable for food-grade applications

- Cleanability

- Easy disassembly for cleaning

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- High moisture content products

- Suited for products

- Whole kernel corn, cooked meats, vegetables

- Machine footprint - Length

- 51.69" (1313 mm)

- Machine footprint - Width

- 32.92" (836 mm)

- Machine footprint - Height

- 71.75" (1822 mm)

- Net Weight

- 1100 lb (499 kg)

- Motor Options

- 15, 30, or 40 HP (11.2, 22.4, or 30 kW)

- Enclosure Type

- Two-piece for simplified disassembly

- Construction Material

- Stainless steel