Compact machining center for high-precision manufacturing

Achieve unparalleled precision and speed in metal machining with this compact solution, designed to enhance productivity in manufacturing top-tier components like smartphone cases and turbine blades, while minimizing downtime with advanced energy-saving features.

Processes Precision Components with High-Speed Machining

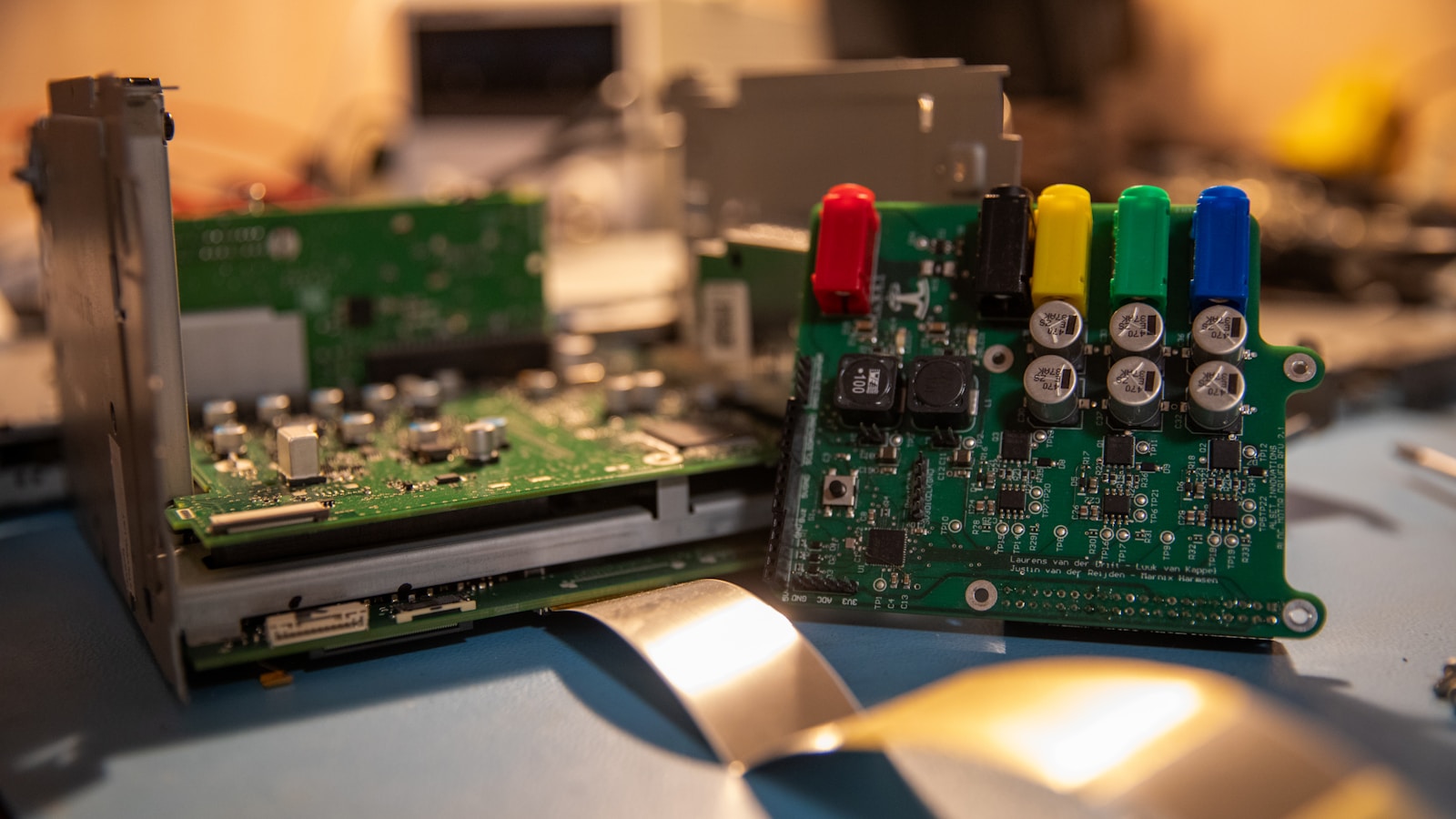

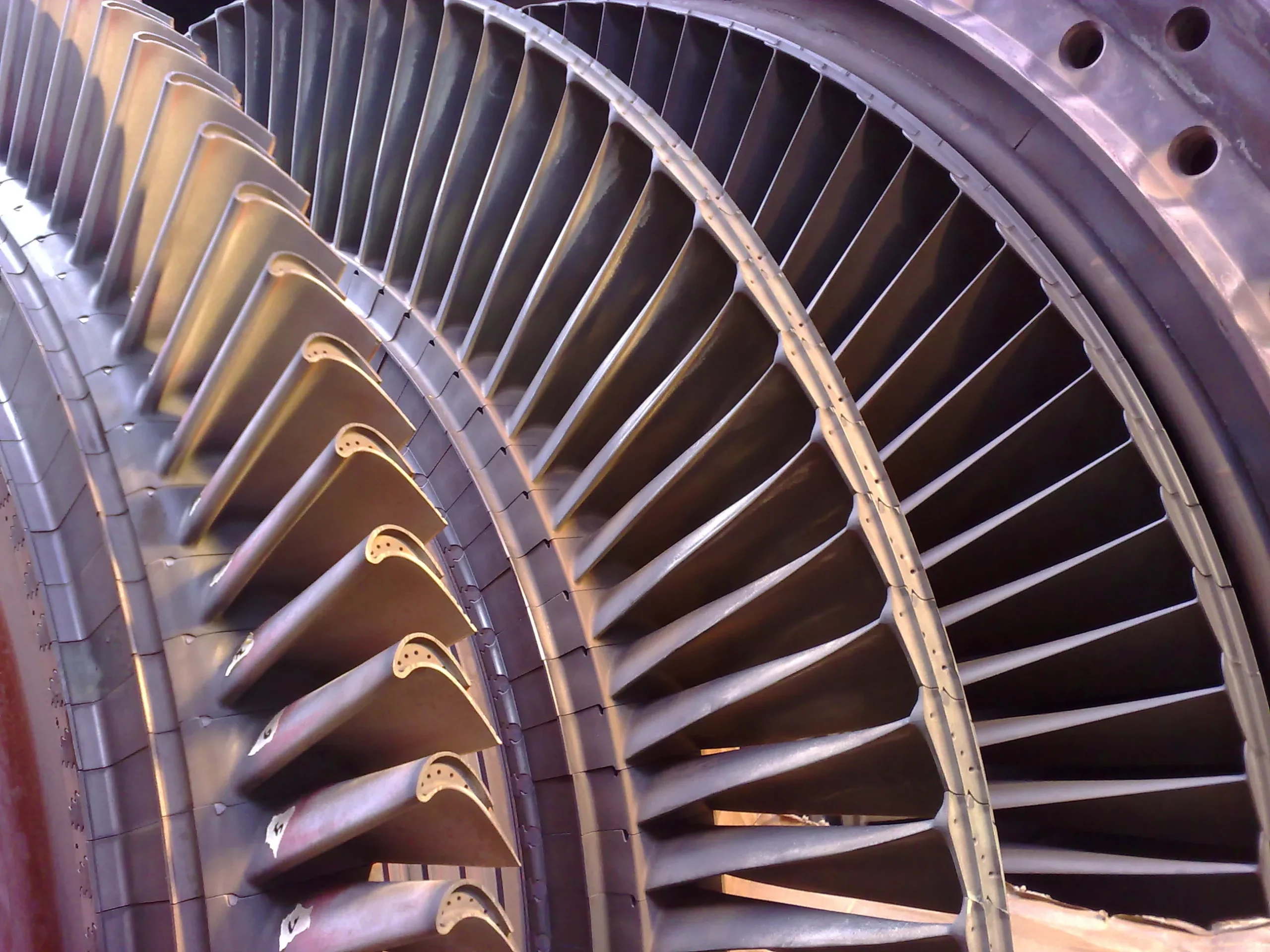

The FANUC ROBODRILL α-DiB Plus series is a compact machining center engineered for high-speed, high-precision operations in industries such as automotive, aerospace, and electronics manufacturing. It stands out with its power supply regeneration system, minimizing energy costs by reusing regenerative energy across factory systems. Equipped with AI thermal displacement compensation, it maintains precision by adjusting for temperature-induced variations, ensuring consistent machining quality. Capable of performing milling, drilling, and tapping processes, this versatile center produces end-products like smartphone cases, orthopedic implants, and turbine blades. It seamlessly integrates into production lines, offering customization options such as temperature sensors for precise environmental adaptation.

Benefits

- Enhances operational efficiency by reducing energy costs through regenerative energy reuse.

- Maintains high precision with AI thermal displacement compensation, adapting to temperature changes.

- Minimizes downtime with real-time adjustments, increasing production reliability.

- Integrates seamlessly into existing production lines, enhancing versatility across various industries.

- Offers environmental adaptability with optional temperature sensors, ensuring consistent quality.

- Applications

- Tooling and dies, Medical devices, Electronics manufacturing, Aerospace components, Metal machining, Precision components, Automotive parts

- End products

- Precision gears, Automotive engine parts, Printed circuit boards, Smartphone cases, Turbine blades, Aerospace brackets, Orthopedic implants, Surgical instruments, Injection molds, Aluminum housings

- Steps before

- Design and Programming, Material Preparation, Tool Selection and Setup

- Steps after

- Part Inspection, Finishing Processes, Assembly

- Input ingredients

- Output ingredients

- Market info

- FANUC is renowned for its expertise in automation, specializing in manufacturing industrial robots, CNC systems, and machine tools, with a strong reputation for reliability and innovation in industrial automation solutions.

- Spindle Taper Size

- No.30

- Performance

- High-speed, high-precision, high-efficiency

- Energy Saving Function

- Power supply regeneration system

- AI Thermal Displacement Compensation

- Real-time compensation with temperature sensors (option)

- High-Speed Operation

- Yes

- High-Precision Performance

- Yes

- High-Efficiency Process

- Yes

- Spindle Taper Size

- No.30

- Minimizing Downtime

- Yes

- Ease of Use

- Yes

- Energy Saving Function

- Yes

- Power Supply Regeneration System

- Yes

- Real-Time AI Thermal Displacement Compensation

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Control panel type

- Standard / Advanced

- Integration possibilities

- Robot Package

- AI Thermal Displacement Compensation

- Optional