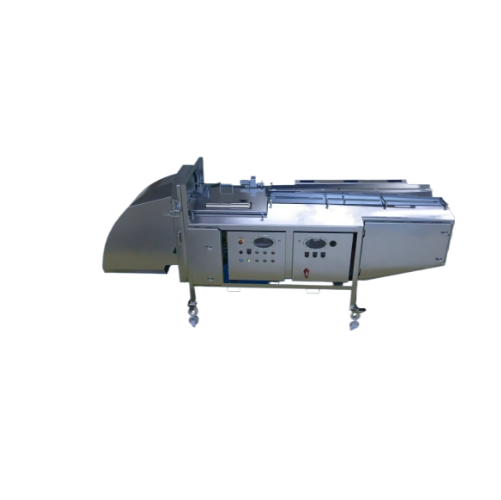

Slicer for elongated products

Effortlessly slice and prepare a wide range of elongated and firm products, transforming your batch processing operations with precision and versatility for high-capacity output.

Slices and Dices Various Food Products

The E TranSlicer® Cutter from Urschel Laboratories offers precise slicing and dicing for diverse food products, including vegetables, fruits, and meats. Incorporating variable frequency drives, it allows for customizable speed control to maintain optimal processing across different products. Its versatility stems from interchangeable stainless steel cutting wheels, enabling various cut types—slices, crinkle cuts, or juliennes—with high accuracy. Ideal for high-capacity batch processing, the E TranSlicer integrates seamlessly into existing lines, boasting a compact footprint and user-friendly electrical enclosure for ease of operation. Conforming to NSF certification, it supports stringent hygiene standards with features like a self-draining frame and polished internal surfaces for efficient cleaning. Engineering support for machine customization ensures that your specific production needs are addressed.

Benefits

- Enhances processing efficiency with precise and diverse cutting capabilities.

- Minimizes labor and maintenance time due to easy-to-clean design features.

- Adapts to various production lines through compact and customizable configuration.

- Ensures high hygiene standards with NSF-compliant self-draining construction.

- Increases operational flexibility with variable speed drives for cutting control.

- Applications

- Meat products, Processed foods, Bakery items, Fruits, Vegetables, Leafy greens, Tubers, Root vegetables

- End products

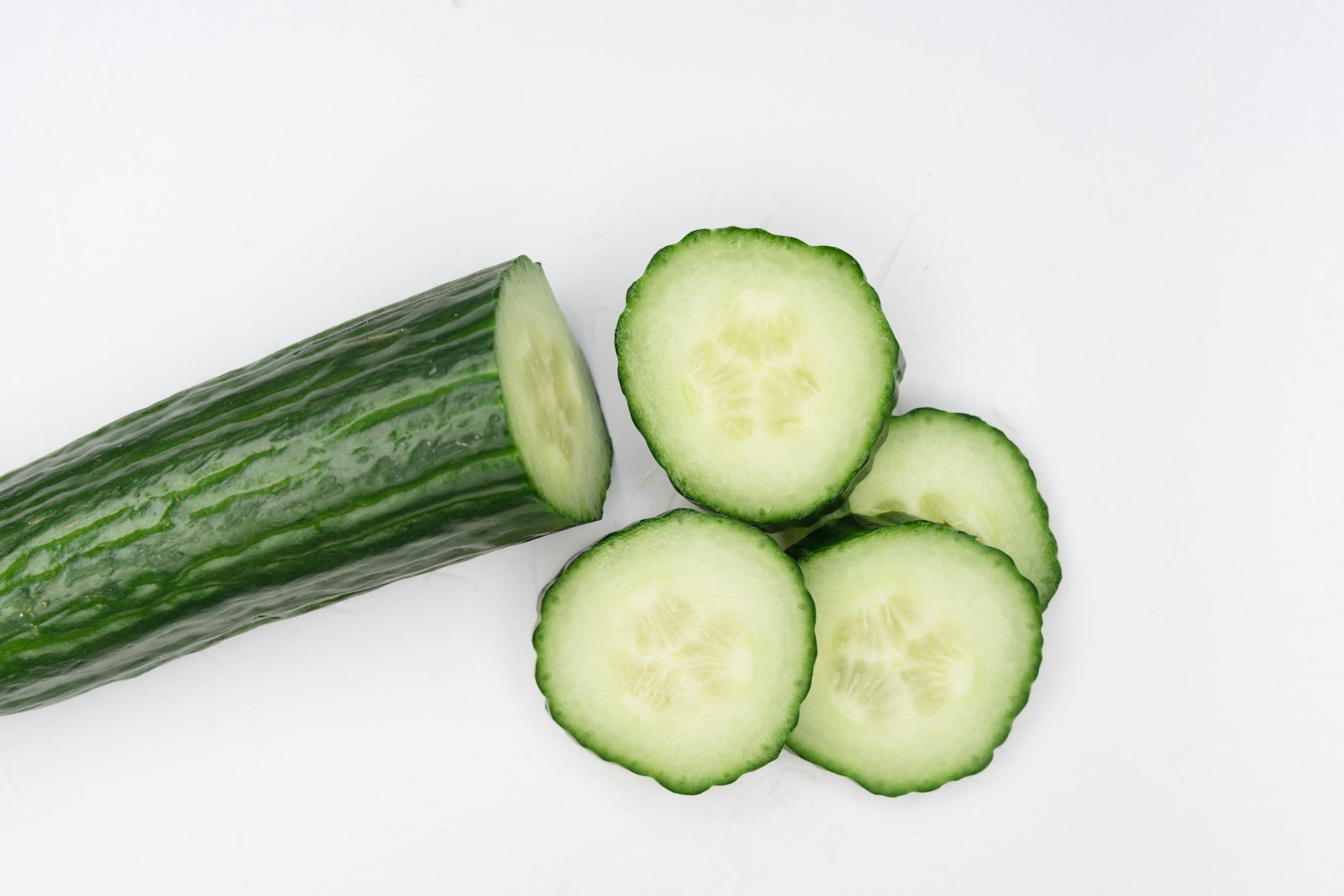

- Pepperoni crinkle slices, Zucchini half moon slices, Carrot bias slices, Green bean slices, Onion slivers, Mango slices, Banana pepper crinkle slices, Baguette slices, Pepper rings, Chicken slices, Eggplant slices, Cucumber slices, Asparagus slices, Lemon slices, Beef stick slices, Leek slices, Pickle slices, Romaine lettuce squares, Celery sticks, Plantain slices, Cassava crinkle slices, Cilantro slices, Green onion slices, Pineapple slices, Jalapeno slices, Sweet potato slices

- Steps before

- Sorting, Washing, Peeling

- Steps after

- Packaging, Quality Control, Distribution

- Input ingredients

- firm products, leafy-type products, asparagus, banana pepper, beef stick, pepper, baguette, carrot, cassava, celery, chicken, cilantro, cucumber, eggplant, green bean, green onion, jalapeno, lemon, mango, onion, pepperoni, pickle, pineapple, plantain, romaine lettuce, sweet potato, zucchini, leek

- Output ingredients

- slices, crinkle slices, bias slices, flat slices, julienne slices, rings, slivers, squares, half moon slices, oval shreds, julienne strips, bias crinkle slices

- Market info

- Urschel is known for its expertise in precision cutting technology and manufacturing industrial food processing equipment, especially cutting machines. It has a strong reputation for quality and innovation in delivering engineered-to-order solutions for the food processing industry.

- Cutting Wheel Motor

- 3 HP (2.2 kW)

- Feed Belt Motor

- 1 HP (.75 kW)

- Conveyor Belt Motor

- 1/4 HP (.19 kW)

- Length

- 100.78" (2560 mm) to 117.26" (2978 mm) with prep table

- Width

- 35.31" (897 mm)

- Height

- 61.79" (1569 mm) to 72.30" (1836 mm)

- Net Weight

- 1, 300 lb (560 kg) to 1, 540 lb (700 kg)

- Flat,Crinkle Slices

- 1/32 to 3" (.8 to 76.2 mm)

- Crinkle Slice Depth

- 1/16" (1.6 mm)

- Julienne Cuts

- 1/2 x 1/2" (12.7 x 12.7 mm) to 2 x 2" (50.8 x 50.8 mm)

- Microslice Thickness

- .020 to .240" (.5 to 6 mm)

- Microslice Crinkle Depth

- .080" (2.0 mm)

- NSF Certification

- Available

- Feed Belt Control

- Variable Frequency Drive

- Slicing Wheel Control

- Variable Frequency Drive

- Changeover Time

- 10 minutes for bias slicing

- Cleaning Method

- Self-draining frame and sloped surfaces

- Automation Level

- Integrated Electrical Enclosure

- Guardlock Indicator Lights

- Illuminates when properly engaged

- Maintenance Accessibility

- Hinged/sliding panels

- Product Flow

- Batch and Inline

- Wheel Changeover

- Cutting wheel retention assembly

- Cleanability

- Easy to clean due to stainless steel

- Corrosive resistance

- Stainless steel for resistance to acids

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 100.78" (2560 mm) length, 35.31" (897 mm) width, 61.79" (1569 mm) height

- Machine footprint with prep table

- 117.26" (2978 mm) length

- Machine footprint with discharge conveyor

- 101.63" (2581 mm) length, 33.99" (863 mm) width, 62.87" (1569 mm) height

- Net weight

- 1, 300 lb (560 kg)

- Net weight with discharge conveyor

- 1540 lb (700 kg)

- Material

- Stainless steel

- Feed method

- Integrated feed belt

- Discharge method

- Hinged discharge chute with optional conveyor

- Access and inspection

- Hinged/sliding panels offering full access

- Self-draining design

- Integrated with sloped surfaces

- Control panel type

- Integrated electrical enclosure with indicator lights

- Discharge method

- Hinged discharge chute with polished internal slope

- Cleaning method

- Self-draining frame with sloped surfaces

- Footprint

- Compact design fitting into existing processing lines

- Customization for Different Cuts

- Interchangeable cutting wheels for slicing, julienne, and bias cuts

- Wheel Changeover System

- Cutting wheel retention assembly for easy changeovers

- Drive System

- Two variable frequency drives for belt and slicing wheel control