Ultrafine bead mill for battery materials

To facilitate the attainment of ultrafine particles and enhance electrode properties, reactivity, and surface structure proper grinding technology and high-quality raw materials should be applied.

Offers grinding and dispersion for NMC, Li-NMC, LNMC, and NCM materials

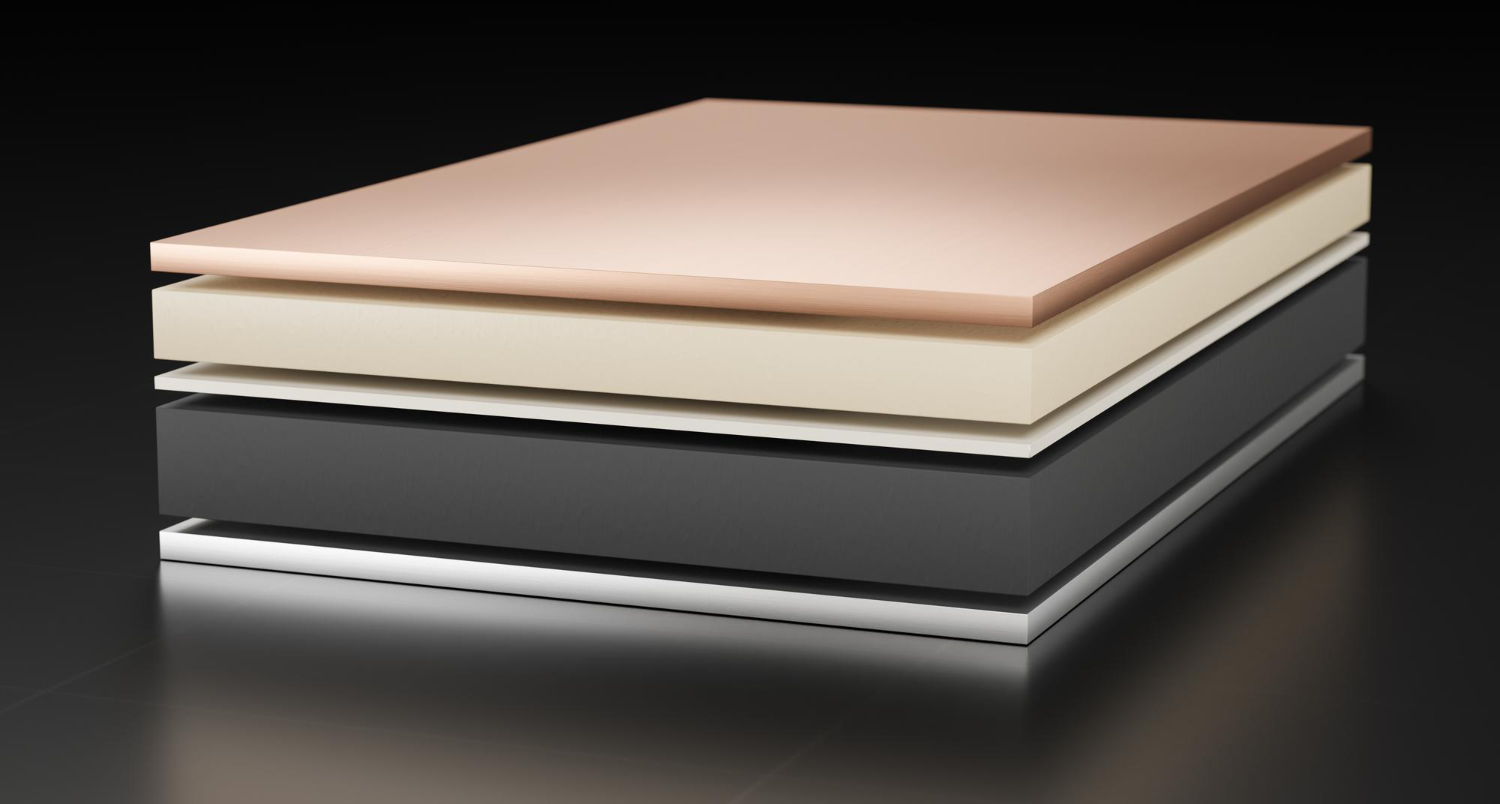

DYNO®-MILL Universal Bead Mill (UBM) from WAB-GROUP® provides dispersion and ultra-fine grinding solutions for a wide range of battery materials from laboratory-scale to large-scale production. The mill is scalable with a grinding chamber volume from 0.5 to 100 l while using grinding media between Ø 0.2 and 2.5 mm. It is suitable for dispersion and grinding of battery materials like anode and cathode materials, fuel cells, carbon nanotubes, multi-layer ceramic capacitors, and photovoltaic and separator materials.

It comprises the DYNO®-DISC BC agitator discs, featuring grinding media channels, which ensure efficient acceleration of the media along a precisely defined path. While in operation, each of the bead channels establishes two grinding circuits between the agitator discs, functioning in opposing directions. The closed outer contour secures the grinding beads between the agitator discs and uniformly distributes them within the active grinding chamber, for dispersion and fine grinding of battery materials.

Benefits

- Ergonomic, user-friendly design for easy operation and cleaning

- Suitable for high throughputs and highly viscous products

- High wear resistance reduces maintenance costs

- Long service life