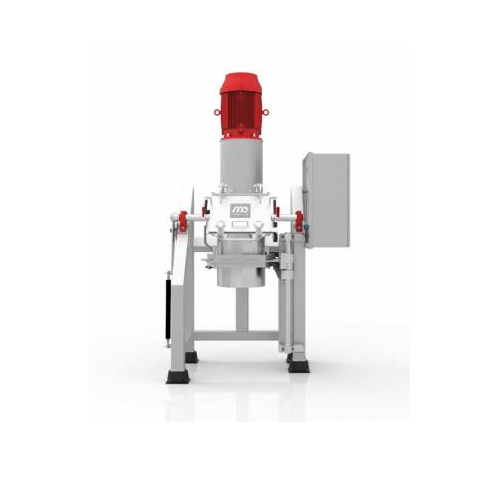

Industrial pulper for fresh produce

Achieve ultra-fine purees and pastes with this high-speed industrial pulper, designed to maintain the integrity and nutrients of fresh produce and alternative materials through efficient blending and pulverizing. Ideal for production lines focused on producing consistent, high-quality end products.

Pulverizes and Blends Fibrous Materials

The Pulper from Dinnissen BV is designed for high-speed pulverizing and blending of fibrous materials in food and feed production. This equipment uses sharp rotating blades to create a vortex, efficiently processing fresh fruits, vegetables, and alternative protein sources into fine purees and pastes. Ideal for applications in the food, pharma, and chemical industries, it produces end-products like fruit purees, algae paste, and plant-based protein powders. With a robust construction, the pulper offers a long service life and minimal heat generation, preserving taste and nutrients. Designed to meet strict hygiene standards, it features ergonomic design for easy filling, emptying, and cleaning. Capable of continuous operation, it integrates seamlessly into existing production lines, and is available with customization options for specific processing requirements.

Benefits

- Enhances product quality by maintaining nutrient integrity and flavor with minimal heat generation.

- Increases processing efficiency with continuous high-speed operation.

- Meets stringent hygiene standards, minimizing contamination risks in the production process.

- Offers flexible application across diverse materials, from fresh produce to protein substitutes.

- Simplifies maintenance and cleaning, reducing production downtime.

- Applications

- Smoothies, Chemicals, Minerals, Protein substitutes, Fresh fruits, Food industry, Insects, Vegetables, Algae, Feed industry, Fibrous materials

- End products

- Mineral slurries, Insect meal, Plant-based protein powders, Fruit purees, Chemical sludges, Cellulose pulp, Smoothie bases, Algae paste, Animal feed pellets, Vegetable purees

- Steps before

- Intake, Conveying, Feeding, Weighing

- Steps after

- Packaging, Filling, Coating, Screening

- Input ingredients

- fresh vegetables, fresh fruits, algae, insects, protein substitutes, fibrous structures

- Output ingredients

- smoothies, processable product, ultrafine pulp, homogeneous pulping, very fine product

- Market info

- Dinnissen is renowned for its expertise in process technology, specializing in innovative solutions for powder handling, mixing, and bulk materials processing for various industries, including food, feed, and chemicals, with a reputation for quality and custom engineered solutions.

- Blade Speed

- High-speed rotating blades

- Pulverizing Capacity

- Designed for large volumes

- Product Fineness

- Very fine product

- Heat Generation

- Minimal heat to preserve nutrients

- Hygiene Standards

- Complies with strictest hygiene requirements

- Cleaning Method

- Easy and thorough cleaning

- Service Life

- Long service life due to robust construction

- Vortex Formation

- Efficient vortex in pulp

- Automation

- Not specified

- Working mechanism

- Rotating blades

- Integrated steps

- Pulverizing and blending

- CIP principles

- Easy to clean

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / PLC

- Energy efficiency

- Low heat generation

- Cleaning method

- Easy and thorough cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Feed/discharge method

- Easy to fill, empty and clean

- Blade type

- Sharp rotating blades

- Ergonomic design

- Designed for fast and safe blending

- Blade configuration

- Customizable for different materials

- Control panel type

- PLC-controlled

- Discharge method

- Customizable per application

- Ergonomic design features

- Customizable operator access