Reaction Flavors Equipment

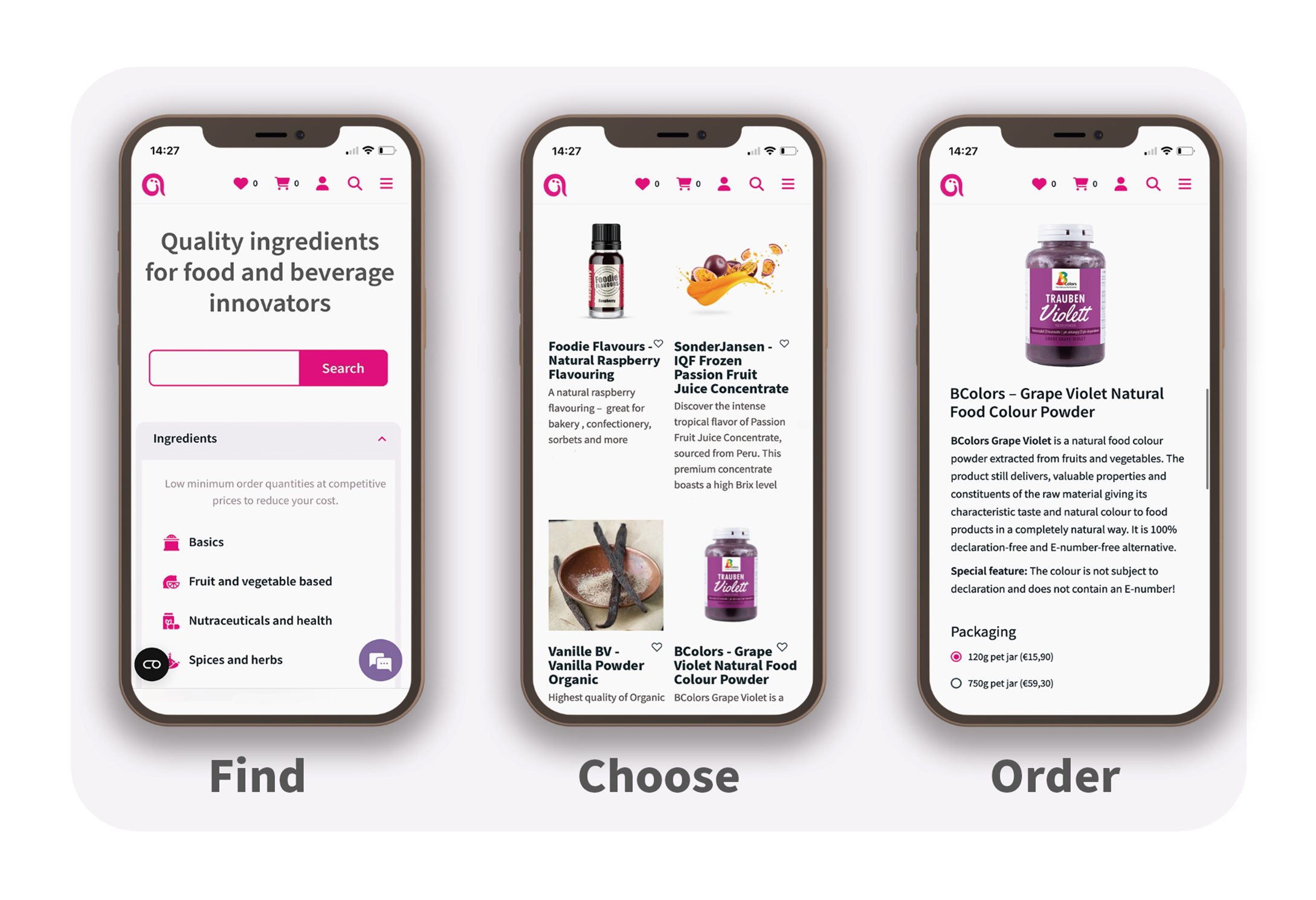

Find innovative production technology for making reaction flavors and connect directly with world-leading specialists

Everything tastes like porridge, the saying goes. That may be an exaggeration, but in theory, reaction flavors could make everything taste the same. Thankfully, flavorists and chemists in the flavor industry are more inventive than that, and colorful process flavors treat our taste buds to a broad palette of sensations, flavors and aromas.

Select your reaction flavors process

Tell us about your production challenge

Evaporate natural substances under vacuum to extract the volatile flavor compounds

Flavor materials from natural raw resources provide a steady base for flavor development. Aromas from citrus materials, for example, can be applied to various flavor blends.

Raise the concentration of the natural substances by reducing water content with vacuum evaporation technology. The volatile aroma compounds escape the material with the water vapor, so you need to condense the evaporate and filter them out. Turn the liquid distillate into solid particles using spray drying technology.

React amino acids with reducing sugar to start the Maillard reaction process

Flavors may be developed by compounding chemicals and flavor materials. Heating a formula of sugar and amino acids produces a substance with flavor value. The Maillard reaction forms a bond between the elements and triggers a series of chemical reactions and responses. The elements are generally some sort of protein with carbohydrates.

A compound recipe involves a specific ratio of reacted chemicals that combine to achieve a familiar flavor. The taste and aroma of a coffee, for example, is an amalgam of organic chemicals working together. The same applies for a seared steak. Another example is the caramelization of onions in sugar which causes a non-enzymatic browning reaction. Also known as the Maillard browning effect which of course gives food that distinct brown color.

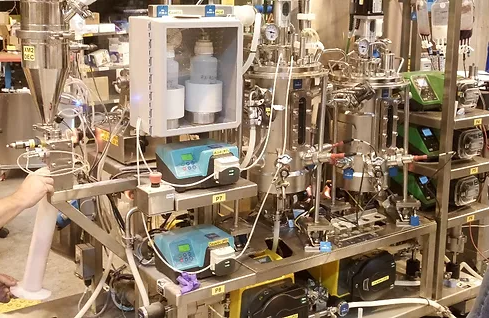

Bring the reaction flavors to a single phase with homogenizing technology

Reaction flavors are developed in one phase, so the materials used must have compatible solubility characteristics. In cases of an immiscible liquid, homogenize the compounded flavors in a reactor to form an emulsion.

Add an emulsifier such as agar-agar to help the oil and aqueous phases disperse uniformly. Other non-reactor additives like starch and gelatin facilitate the stability of the emulsion.

Apply gentle drying techniques to preserve the aromas and tastes

Reaction flavors are formulated in powder form to obtain a controlled release. Subject the liquid phase to vacuum evaporation to remove the moisture from the mixture.

Aromas are typically produced from heat-sensitive compounds. The drying process, therefore, needs to be gentle enough not to destabilize them or initiate a premature reaction in the compound. Oxidation presents another risk, but this can be addressed with a closed system.

Synergize flavor profiles to enhance natural tastes and aromas

Process flavors have long been used in food science to intensify tastes in products such as fruit-based juices or jams. Another classic application is taste-masking in pharmaceutical products.

But a growing range of alternatives to animal-derived products, like plant-based meat, is opening new applications for reaction flavors manufacturing. Together with texture, taste and aromas are essential for customer acceptance of meat substitutes. One promising direction is cultivated meat, as food technologists strive to create flavors that consumers recognize.

Develop creative palate sensations with process flavors technology

The work of flavorists, however, is not merely mimicking familiar flavors. A flavor palette allows food manufacturers to experiment with new sensory cues. Besides odors, fragrances and tastes, products have a trigeminal dimension evoking sensations such as cooling, dryness, or smokiness.

Thanks to reaction flavors, food engineers bring novel combinations to the market. Try a hot and sweet palate that tastes like spicy honey or a fresh and bitter sensation like minty grapefruit.

Processing steps involved in reaction flavors making

Which reaction flavors technology do you need?

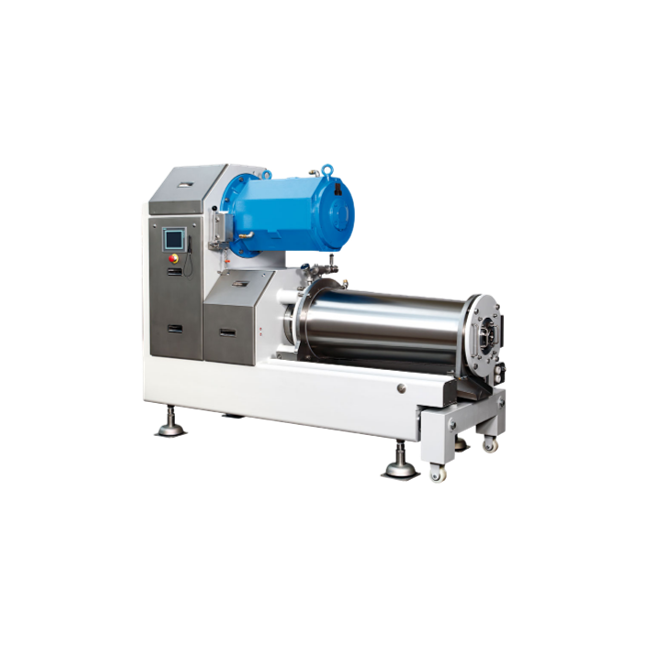

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

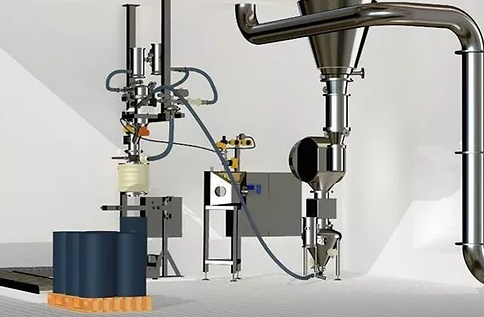

High-speed powder dosing system

Balancing speed and accuracy in powder dosing is crucial to fulfilling production viability....

Contamination free filling system

Liners for powder handling across industries must prevent contamination of materials to c...

Small-scale laboratory dispersing machine

Developing and validating new processes requires reliable and highly versatile e...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Industrial freeze-dryer for fruits

Freeze-drying is a complex and delicate process. If you are searching the market for a f...

Gravimetric powder microdosing 2 - 100 g

Powders and granules are commonly dosed for the manufacturing of pharmaceuticals, ...

Gravity feed cooler

The food and feed industry has high food safety requirements making frequent cleaning and inspection nece...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Bin blender

Many pharmaceutical processes require the blending of powders or other granular ingredients, the mixing of settled...

Waterproof checkweigher

Features waterproof and dust proof cabinet and components. Its hygienic design is perfect for unpacke...

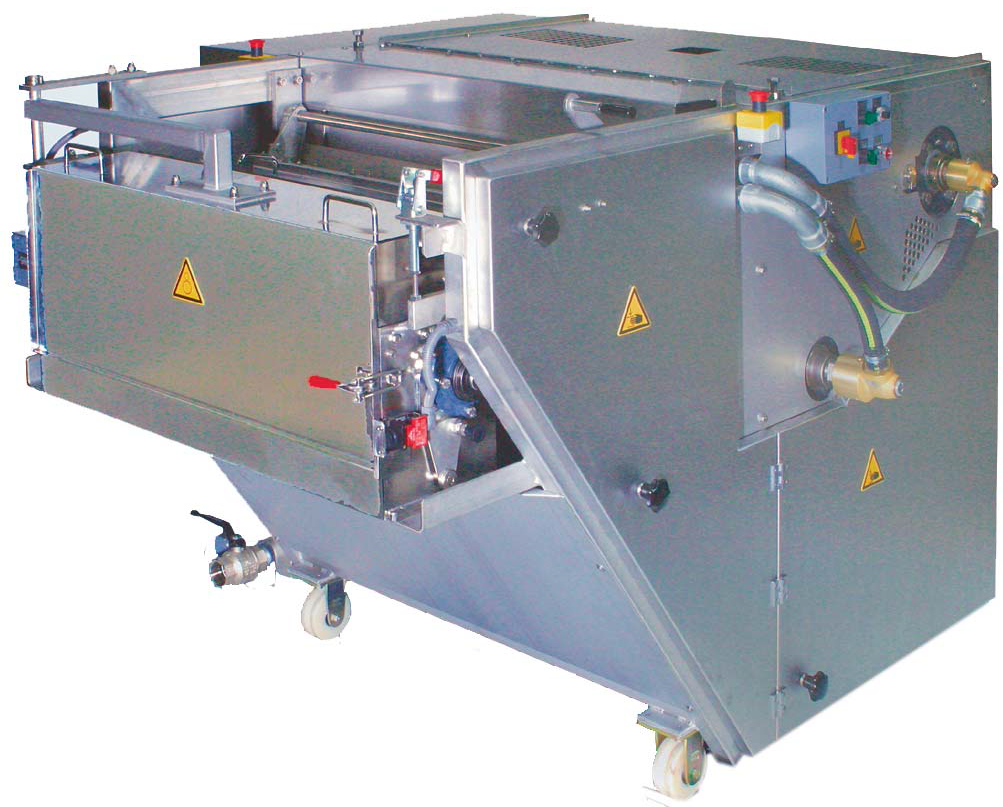

Drum cooler for hot melt processes

Medium-scale production of extruded hot melt masses benefits from reliable, efficient co...

GMP cooler for hot melt extrusion

Pharmaceutical production of extruded hot melt masses requires a GMP designed, FDA approv...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...

Dilution system for two or more liquids in one pass

Onsite dilution of liquid process ingredients has historically been a...

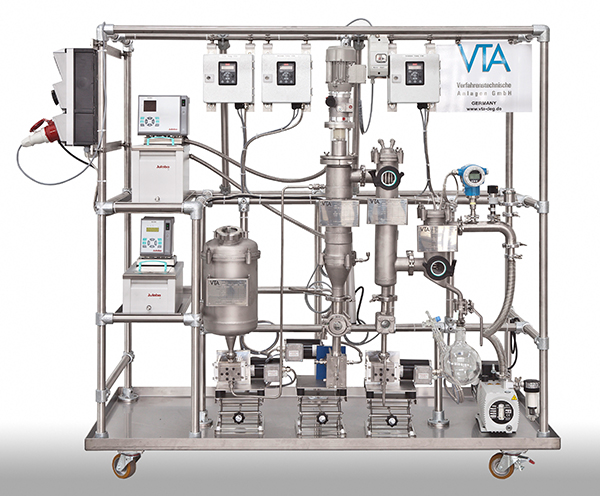

Pilot multi-stage distiller

If generating an scalable data and bring in results with small sample quantities of high-boiling...

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

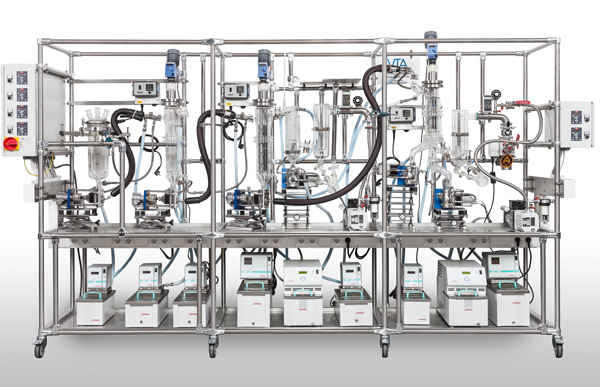

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...

Isolator centrifuge

For transferring highly active pharmaceutical ingredients (HAPI) without contamination from the isolator ...