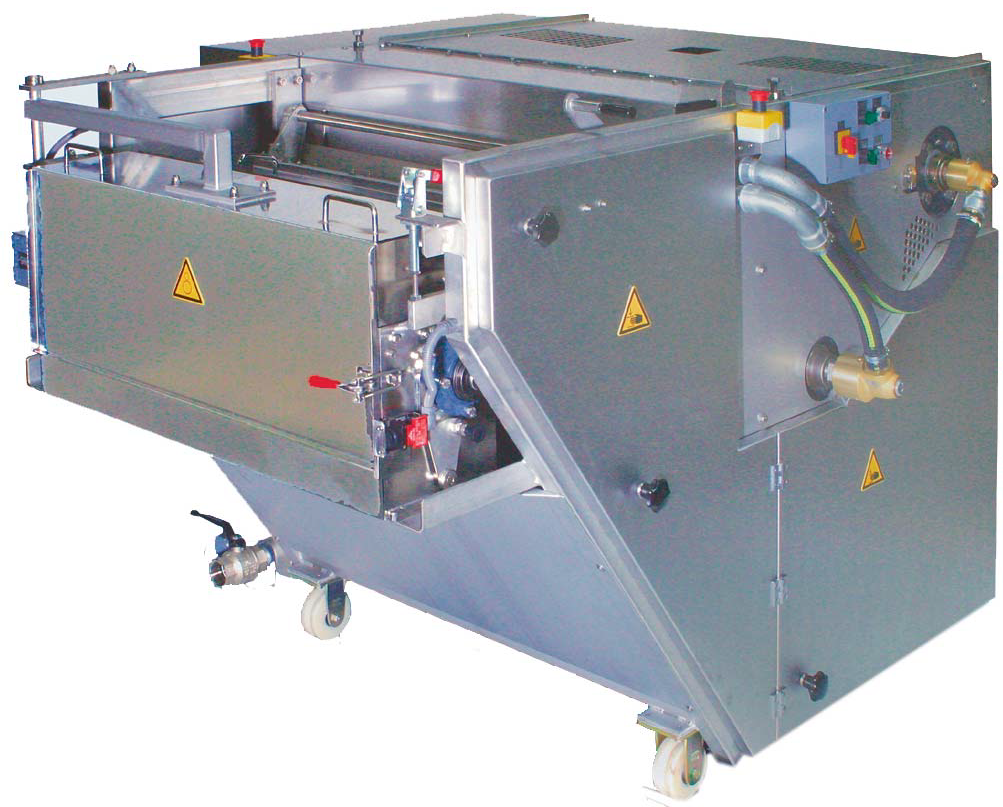

Drum cooler for hot melt processes

Medium-scale production of extruded hot melt masses benefits from reliable, efficient cooling technology. This all-in-one solution offers excellent throughput in a small form factor that’s easy to use and delivers consistent results – all while using less energy.

Efficient medium-scale production drum cooler for solidification of viscous hot melt products

The BBA Innova CCC95 drum cooler is a highly efficient drum cooler designed for continuous operation and is available in 450kg per hour and 750kg per hour throughput variants depending on your requirements.

The innovative design has enabled a small footprint machine with excellent efficiency that is flexible enough to fit almost anywhere.

The closed water loop cooling media provides highly consistent results and means energy consumption of under 2.5kW.

Built in crusher unit is optimized for a narrow distribution of chip sizes, and optional micro-crusher shaft is available for fine finishing.

Benefits

- Compact unit takes up minimum space without compromise on throughput

- Designed specifically to allow easy access for cleaning, minimizing downtime for changeover

- High efficiency cooling means low energy consumption and low running costs

- Fully adjustable to allow for changes to product thickness to suit your exact requirements