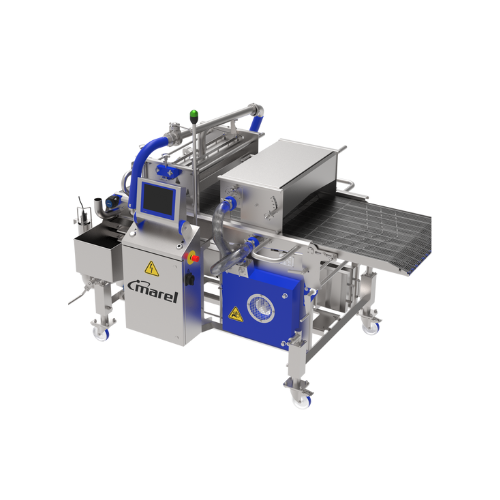

Batter applicator for plant-based products

Achieve flawless coating with precision technology that ensures complete wet and dry coverage, enhancing the texture and quality of plant-based and alternative protein products.

Applies Uniform Wet Coating for Alternative Proteins

The Active Batter Applicator from Marel is engineered to revolutionize your plant-based and convenience food production line. This specialized coating machine delivers superior wet coverage using a unique bed-of-batter technique, ensuring comprehensive underside coating without belt marks. Ideal for products like vegetarian chicken nuggets and tempura vegetables, it integrates seamlessly in high-speed operations with continuous processing. Capable of handling liquid and slurry product types, the applicator features an innovative air-knife system for consistent batter pick-up and optimal yield. Available in various belt widths, it supports customization to fit diverse production requirements. Enhance your operation’s efficiency with automated control via Innova Food Processing Software, which optimizes throughput and ensures compliance with food safety standards. Designed for easy maintenance, Marel’s global network ensures prompt support and quality spare parts to keep your equipment at peak performance.

Benefits

- Enhances product quality by eliminating belt marks and ensuring uniform coating.

- Boosts production yield with consistent and controlled batter application.

- Reduces operational costs through efficient use of batter and reduced waste.

- Supports flexible production with customizable belt widths for various product sizes.

- Facilitates seamless integration with Innova software for optimal processing control.

- Applications

- Wet coating, Convenience products, Plant-based products, Food processing, Coated products, Dry coating, Alternative protein

- End products

- Tofu schnitzels, Vegetarian chicken nuggets, Lentil-based nuggets, Quinoa patties, Plant-based burger patties, Tempura vegetables, Soy-based tenders, Breaded meatless balls, Seitan cutlets, Vegan fish fillets

- Steps before

- Preparation, Wet-coating mixing

- Steps after

- Dry coating, Air-knife application, Packing, Food safety checks, Yield optimization

- Input ingredients

- alternative protein products, highly viscous batters

- Output ingredients

- products with even, consistent coating, flawless layer of dry coating

- Market info

- Marel is known for its advanced food processing equipment, specializing in systems and services for poultry, meat, and fish industries. It is recognized for innovation, quality, and improving processing efficiency and sustainability.

- Line Speed

- up to 25 meters per minute

- Belt Width

- 600, 700, 1, 000 mm

- Coverage Control

- Full top and bottom coverage

- Air-knife System

- Ensures equal airflow for consistent coverage

- Working mechanism

- Bed of batter, curtain flow system

- Integrated steps

- Batter application, air-knife excess removal

- Automation level

- PLC controlled

- Cleaning method

- CIP (Clean-in-place) compatible

- Batch vs. continuous operation

- Inline continuous

- Changeover time

- Minimal due to inline design

- Energy efficiency

- Optimized airflow for reduced energy consumption

- High line speed

- Up to 25 meters per minute

- Air incorporation control

- Uniform airflow ensures consistent coating

- Pick-up rate

- High due to superior batter coverage

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Suitable for various sizes

- Machine footprint

- Compact design fits into existing production lines

- Belt width options

- 600, 700, 1, 000 mm

- Bed of batter transfer

- Ensures complete underside coating

- Air-knife system

- Provides uniform airflow to ensure consistent coverage

- Discharge method

- Air-knife blows off excess batter

- Belt width options

- 600, 700, 1000 mm