Viscous coating applicator for poultry, meat & seafood

Effortlessly apply even viscous coatings like tempura or marinades with precision, ensuring consistent flavor and texture across BBQ products, seafood, and plant-based alternatives.

Efficiently Coats and Processes Viscous Products

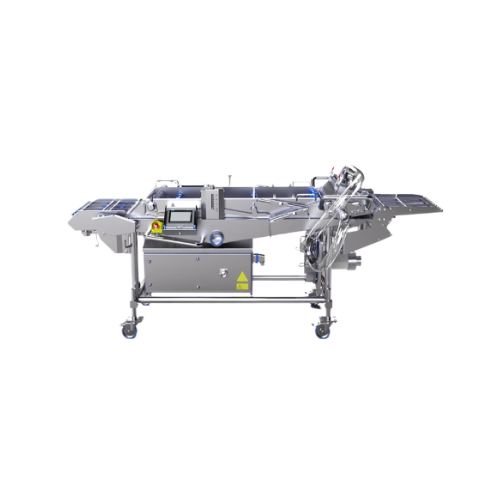

The alco Dipper – ADT from JBT stands out in industrial coating applications, offering a streamlined approach to applying viscous coatings across a range of products, including BBQ chicken wings and tempura shrimp. This dipper machine utilizes a belt system that efficiently guides products through a coating bath, eliminating the need for pumping viscous materials. Available in 400 to 1,000mm belt widths, it’s designed for high-speed, continuous operations within food processing lines.

Its PLC control allows seamless integration with existing systems, offering user-friendly recipe management through a touch panel. An integrated adjustable blower system and air knife ensure precise excess material removal, enhancing product consistency. Constructed from stainless steel and food-approved plastics, this machine is easy to clean without dismantling, featuring outlet openings for straightforward maintenance. An optional double-wall design offers coolant injection capabilities, maintaining optimal coating material temperatures for diverse applications. Tailor your production line with additional accessories, such as a batter mixer, to enhance your coating efficiency.

Benefits

- Ensures precise and consistent coating, enhancing product quality and taste.

- Streamlines operations with seamless integration into automated production lines.

- Reduces labor requirements with easy-to-clean design and minimal maintenance.

- Enhances production versatility, accommodating a variety of viscous coating materials.

- Minimizes waste through efficient excess coating removal and material return system.

- Applications

- Bbq products, Plant-based meat alternatives, Nuggets, Fried fish, Vegetables, Tempura coated products

- End products

- Chicken nuggets, Battered vegetables, Fish and chips, Bbq chicken wings, Tempura shrimp, Plant-based chicken nuggets

- Steps before

- Grinding, Mixing, Marination, Preparation, Fresh Cut Processing

- Steps after

- Frying, Freezing, Chilling, Packaging, Tray Sealing

- Input ingredients

- viscous coating materials, heavy liquid batters, tempura, marinades, BBQ marinade, tempura batter

- Output ingredients

- BBQ products, tempura coated products, fried fish, nuggets, vegetables, plant-based meat alternatives

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Automation

- PLC-controlled

- Control panel type

- Touch panel

- Belt Width

- 400, 600, 700, 1.000mm

- Material

- Stainless steel and food-approved plastic

- Coating method

- Belt-guided immersion

- Cleaning method

- Easy-to-clean design without dismantling

- Excess material removal

- Adjustable blower system

- Cooling option

- Double-wall design with coolant injection

- Working mechanism

- Upper and lower belt guide

- Integrated steps

- Coating, excess removal

- Automation level

- PLC-controlled

- Cleaning method

- Easy-to-clean design

- Coating method

- Bath immersion

- Batch vs. continuous operation

- Continuous

- Excess removal system

- Adjustable blower system

- Viscous coating materials

- Batter, Tempura, Marinades

- Stainless steel

- Yes

- Food-approved plastic

- Yes

- Corrosion resistance

- Yes

- Viscosity of coating material

- High viscosity suitable for non-pumpable materials

- Coating thickness control

- Adjustable blower system to control thickness

- Material removal method

- Light air knife system

- Product types

- BBQ, tempura, fried fish, nuggets, vegetables

- Material compatibility

- Suitable for stainless steel and food-approved plastic

- Cleaning method

- Easy-to-clean without dismantling

- Temperature control

- Optional coolant injection in double-wall design

- Belt width

- 400, 600, 700, 1000 mm

- Material

- Stainless steel and food-approved plastic

- Design

- Easy-to-clean, no parts dismantling required

- Additional accessories

- Batter mixer for automatic mixing and filling

- Outlet belt

- Pivotable for optimal product transfer

- Cooling option

- Optional double-wall design for coolant injection

- Control panel type

- Touch panel with recipe management

- Belt width options

- 400, 600, 700, 1000 mm

- Discharge method

- Pivotable outlet belt

- Material cooling options

- Optional double-wall design for coolant injection

- Integrated system controls

- PLC control, user-friendly interface