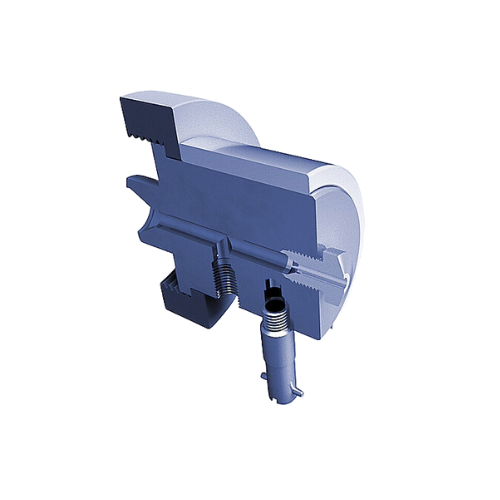

Round strand die head for precision extrusion

Achieve precise extrusion control across varied applications with our customizable die head, offering seamless integration with your extrusion processes for enhanced product consistency and efficiency.

Extrudes and Cuts Polymers and Inorganic Materials

The Round Strand Die Head by Brabender is engineered to provide precision and flexibility in extrusion processes across diverse industries, including chemicals, food, and energy. This equipment excels in shaping and cutting polymers, elastomers, and inorganic materials into uniform strands or granules, perfect for manufacturing plastic pellets, rubber gaskets, and silica gel beads.

Equipped with a heating collar and customizable die diameters from 1 mm to 7 mm, it accommodates various product formulations, ensuring compatibility with multiple screw-in die types. Its integration with a cutting device makes it unique, facilitating simultaneous extrusion and cutting operations, which simplifies production workflows.

Supporting both manual and pilot operations, the Round Strand Die Head effectively serves research and development purposes as well as small-scale production facilities. Its adaptable design allows it to be part of a comprehensive extrusion line, ensuring seamless operation from raw material processing to final product output.

Manufactured for robustness, this machinery offers material options suited for resistance to chemicals and wear, making it durable under rigorous processing conditions commonly found in industries like petroleum and mining. With the potential for customization and engineering support, it is an ideal solution for those requiring tailored extrusion solutions.

Benefits

- Enhances production versatility with adjustable die diameters for various product sizes.

- Integrates cutting technology to streamline and accelerate the extrusion process.

- Reduces material waste through precise control and uniform product output.

- Supports R&D and production flexibility, making it ideal for pilot operations.

- Durable against chemical exposure, ensuring long-term use in harsh industrial settings.

- Applications

- Polymers, Ceramics, Building materials, Grain, Elastomers, Additives, Lubricants, Starch, Inorganic chemicals

- End products

- Wheat gluten, Silica gel beads, Cornstarch, Porcelain tiles, Antifreeze solution, Engine oil additives, Rubber gaskets, Plastic pellets, Concrete mix fibers

- Steps before

- Material Preparation, Compounding, Pre-heating

- Steps after

- Cutting, Cooling, Pelletizing

- Input ingredients

- screw-in dies, materials for extrusion, inorganic chemicals, polymers, elastomers

- Output ingredients

- extruded products, round strand extrusions, building materials, ceramics, grain and starch

- Market info

- Brabender is renowned for producing high-quality, engineered-to-order lab equipment for material testing, particularly in food and plastics industries, specializing in precision instruments for measuring, preparation, and processing.

- Die Head Diameter

- 1 mm to 7 mm

- Cutting Device Compatibility

- Available

- Heating capability

- Collar heating

- Die diameter range

- 1 mm to 7 mm

- Compatibility with cutting device

- Can be equipped

- Extrusion capability

- Screw-in nozzles

- Automation level

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Die Diameter Range

- 1 mm to 7 mm

- Heating Collar

- Equipped

- Cutting Device Option

- Available

- Die diameter range

- 1 mm to 7 mm

- Heating collar

- Equipped

- Cutting device

- Optional