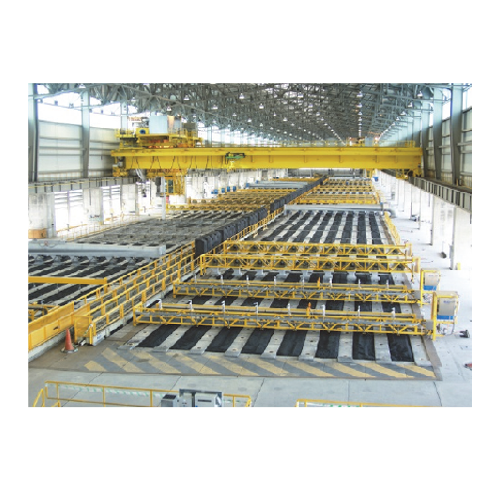

Carbon baking furnace for anode and electrode production

Optimize your carbon product baking process with high-capacity furnaces designed for precise anode and electrode heating, ensuring superior product quality and operational efficiency.

Bakes Anode Blocks for Aluminium Production

The ABF – Open Type Ring Pit Furnace from RIEDHAMMER, a leader in the carbon products industry for nearly a century, specializes in the baking of anode blocks vital for aluminium production. This furnace is engineered for continuous operation, utilizing a design that accommodates up to 4 fires, with 16-18 sections per fire and 6-10 pits per section, ensuring high throughput and consistency. Ideal for aluminium producers requiring precision baking, the ABF furnace is a robust solution that seamlessly integrates into existing production lines. Its optimized heat distribution ensures uniform baking, enhancing the quality and lifespan of anode blocks. The system supports energy efficiency with its advanced firing technology, reducing operational costs. Available with engineering support for custom configurations, the ABF furnace is tailored to meet specific production needs, ensuring compatibility with industry standards and operational demands.

Benefits

- Ensures consistent anode quality with precise heat distribution.

- Enhances operational efficiency with continuous processing capabilities.

- Reduces energy consumption through optimized firing technology.

- Integrates seamlessly into existing production lines with customizable configurations.

- Minimizes labor costs with efficient multi-stage operation.

- Applications

- Steel industry, Carbon products, Cathodes, Aluminium industry, Electrodes, Anodes

- End products

- Anode blocks, Carbon cathodes, Graphite electrodes, Pre-baked carbon anodes, Carbon nipples, Cathode blocks, Steel electrode rods

- Steps before

- Design, Engineering, Construction

- Steps after

- Packing, Quality Assurance

- Input ingredients

- carbon, anodes, electrodes, cathodes, fine grain carbon, carbon blocks, nipples

- Output ingredients

- baked anodes, baked electrodes, baked cathodes, baked carbon blocks, baked nipples

- Market info

- Sacmi is renowned for manufacturing advanced industrial equipment, primarily focusing on ceramics, packaging, and food processing. With a commitment to innovation and quality, Sacmi is a market leader in providing engineered-to-order solutions across various sectors.

- Baking capacity

- High

- Baking type

- Continuous / Batch

- Furnace type

- Open Type Ring Pit / Closed Type Ring Pit / Car Bottom

- Product dimensions

- Anodes and Cathodes up to specified lengths

- Maximum electrode length

- 3, 200 mm

- Maximum cathode length

- 4, 200 mm

- Automation

- Customizable based on client needs

- Furnace Type

- Open Type Ring Pit / Closed Type Ring Pit / Car Bottom

- Material Processed

- Anodes / Cathodes / Electrodes

- Baking Capacity

- High

- Operation Type

- Continuous / Batch

- Application Industry

- Aluminium / Steel

- Maximum Length

- Electrodes

- Number of Sections per Fire

- 16-18

- Number of Pits per Section

- 6-10

- Fires

- Up to 4

- Thermal resistance

- High-temperature carbon baking

- Metals and carbon materials

- Anodes, cathodes, electrodes

- Suitable Material

- Anodes / Cathodes / Electrodes / Carbon Blocks

- Machine footprint

- Customizable per customer requirements

- Furnace type

- Open type Ring pit / Closed Type Ring pit / Car bottom

- Section configuration

- 16-18 sections per fire

- Fire pits per section

- 6-10 pits per section

- Electrode baking length

- up to 3.200 mm

- Cathode baking length

- up to 4.200 mm

- Furnace Design

- Open Type Ring Pit / Closed Type Ring Pit / Car Bottom

- Baking Capacity

- High capacity

- Control Panel Type

- HMI / PLC-controlled

- Integration Possibilities

- Customizable to technical conditions

- Pit Configuration

- 6-10 pits per section

- Sections Per Fire

- 16-18 sections

- Electrode Length

- Up to 3, 200 mm

- Cathode Length

- Up to 4, 200 mm