Fluid bed drying system for wet powder chemicals

Achieve efficient large-scale drying and cooling of wet powder chemicals with precise control over evaporation and fluidization, ensuring consistent product quality and optimized thermal efficiency in your production line.

Dries and Cools Wet Powder and Bulk Products

The CONTACT FLUIDIZER Fluid Bed from GEA is designed to address the challenges of drying and cooling large volumes of wet powders and bulk chemical products. Engineered for the chemical, food, and pharmaceutical industries, this equipment uses a dual-section fluidization process to ensure continuous operation and precise control over drying and cooling phases. It features a back-mix section for initial evaporation, followed by a plug flow area for uniform product movement, achieving optimal moisture and temperature control. Suitable for products like detergent powder, mineral fillers, and pharmaceutical excipients, it delivers consistent output with an average particle size ranging from 50 to 800 μm. The integration of submerged heating panels within the fluidized bed reduces energy usage, while the GILL PLATE ensures uniform gas distribution, enhancing thermal efficiency and operational reliability. Available in open or closed-cycle configurations to handle various feed types, this system minimizes cleaning downtime with optional CIP systems, fully aligning with GEA’s commitment to efficient, scalable, and customizable fluid processing solutions.

Benefits

- Enhances processing efficiency with low specific energy consumption.

- Ensures uniform product quality through controlled drying and cooling phases.

- Minimizes operational disruptions with even gas distribution and effective system emptying.

- Adapts to versatile manufacturing needs with open and closed-cycle configurations.

- Reduces maintenance time with optional CIP systems for efficient cleaning.

- Applications

- Organic solvent-wetted powders, Chemical bulk products, Powdery water-based feeds, Wet powder

- End products

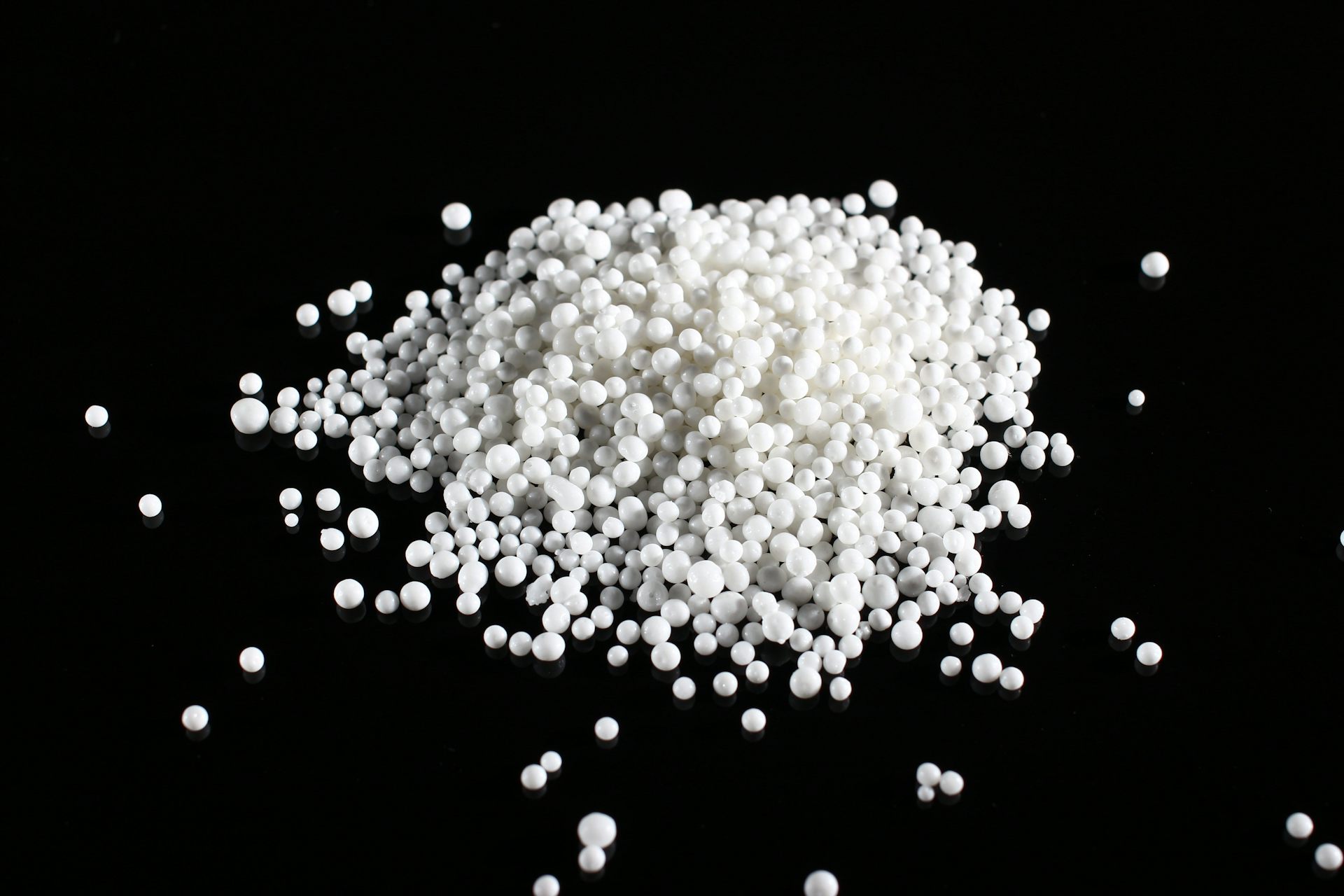

- Detergent powder, Polyethylene powder, Cellulose acetate, Ammonium nitrate, Agrochemical dispersions, Plastic granules, Urea granules, Catalyst powders, Pharmaceutical excipients, Mineral fillers

- Steps before

- Grinding, Emulsification, Mixing

- Steps after

- Cooling, Particle Separation, Packing

- Input ingredients

- wet powder, wet feed material, powders wetted with organic solvents, powdery water based feeds

- Output ingredients

- dried powder, semi-dried powder, cooled product

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Drying process type

- Fluid bed drying

- Design type

- Compact

- Thermal efficiency

- High

- Gas throughput

- Low

- Particle size range

- 50–800 μm

- Product residence time

- Long

- Drying profile

- Optimized

- Energy consumption

- Low specific energy

- Air flow

- Low specific air flow

- CIP System

- Available / Not Available

- Cooling option

- Internal cooling panels

- Working Mechanism

- Fluidized bed drying

- Integrated Steps

- Back-mix and plug flow sections

- Batch vs. Continuous Operation

- Continuous

- CIP/SIP

- Available w/o CIP system

- Energy Efficiency

- Low specific energy consumption

- Automation Level

- Controlled residence time

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Particle size range

- 50-800 μm

- Machine Footprint

- Compact design

- Control Panel Type

- Available

- Discharge Method

- Lump and effective emptying

- Feed Method

- Rotary Feed Spreader

- Fluid Bed Type

- Open system / Closed-cycle system

- Plug Flow Section

- Controlled Residence Time, potential cooling