Filling system for consumer healthcare products

For small to medium productions needing versatile filling and sealing, this advanced system efficiently handles liquids from cough syrups to glucose test solutions, ensuring precision and control in every batch.

Fills and Caps Liquid Products in Small Batches

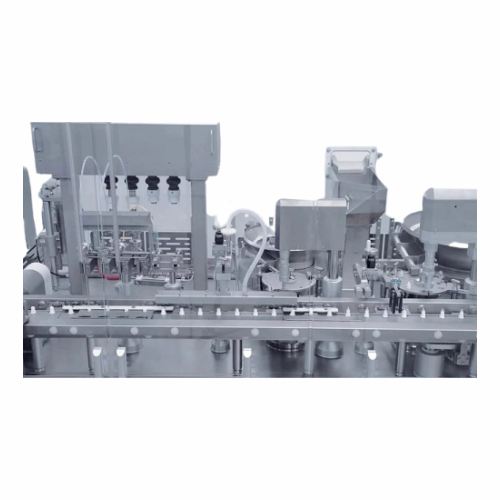

The Flexcare 10 from Groninger is a versatile filling and capping machine tailored for consumer healthcare, pharmaceutical, diagnostic, and dietary supplement manufacturers. This compact system excels in processing small batches of liquid products like cough syrups, eye drop solutions, and vitamin supplements. With capabilities including pre- and post-gassing, filling, and screwing, the Flexcare 10 ensures precise weight control and reliable sealing of glass and plastic bottles. It supports a range of filling systems, accommodating rotary piston pumps or peristaltic pumps based on product needs. Operating at speeds up to 70 containers per minute, it handles volumes from 1 to 400 ml, while its tool-free format changeover minimizes downtime. The machine’s GMP-compliant design integrates seamlessly into production lines, offering laminar flow attachment for contaminant-free filling. Furthermore, the Flexcare 10 provides customization options to meet specific process requirements, backed by Groninger’s engineering support for optimal production efficiency.

Benefits

- Enhances productivity by efficiently processing up to 4,200 objects per hour.

- Minimizes changeover time with tool-free format transitions, improving system availability.

- Ensures precise fill volumes and weight control for consistent product quality.

- Integrates seamlessly with existing lines, reducing setup time and complexity.

- Complies with GMP standards, ensuring regulatory adherence for consumer healthcare products.

- Applications

- Glass and plastic bottles, Consumer healthcare, Non-sterile pharma products, Diagnostics, Dietary supplements

- End products

- Glucose test solutions, Liquid cough syrups, Vitamin liquid supplements, Liquid antacids, Plastic vitamin containers, Probiotic solutions, Nasal sprays, Eye dropper solutions, Glass tincture bottles, Dietary supplement oils

- Steps before

- Purification, Drying, Pre-gassing

- Steps after

- Post-gassing, Crimping, Packing, Torque-monitored pre- and post-screwing

- Input ingredients

- glass bottles, plastic bottles, non-sterile pharma products, diagnostics, dietary supplements, droppers, spray pumps, caps

- Output ingredients

- filled glass bottles, filled plastic bottles, sealed bottles with droppers, sealed bottles with spray pumps, sealed bottles with caps

- Market info

- Groninger is known for its expertise in manufacturing high-quality filling and packaging machinery for the pharmaceutical, cosmetics, and consumer healthcare industries, with a strong reputation for innovation, precision engineering, and customer-focused solutions.

- Output

- 4, 200 objects per hour

- Processing range

- 14-60 mm

- Filling volume

- 1-400 ml per object

- Filling speed

- Up to 70 objects per minute

- Filling systems

- Rotary piston pump or peristaltic pump

- Compliance

- GMP friendly and LF compliant design

- Weight control

- Fully automatic in-process control

- Size

- Compact system design

- Changeover

- Tool-free format part changeover

- Components

- Closing with up to 2 components

- Flexibility

- High flexibility and system availability

- Working mechanism

- Filling and sealing of glass and plastic bottles

- Batch vs. continuous operation

- Batch

- Changeover time

- Tool-free, quick, and easy

- Automation level

- PLC-controlled

- CIP/SIP

- Manual cleaning

- Cleaning method

- Manual

- In-process control

- Fully automatic weight control

- System flexibility

- Adaptable to various functions like pre-gassing and crimping

- Viscosity

- Low to medium

- Container size

- 14-60 mm

- Container material

- Glass / Plastic

- Filling volume

- 1-400 ml

- Aero-sensitivity

- Yes

- Heat sensitivity

- No

- Foaming

- No

- Closure type

- Dropper / Spray Pumps

- Machine footprint

- Compact

- Material compatibility

- Glass / Plastic

- Filling volume range

- 1–400 ml per object

- Processing range

- 14–60 mm

- Output speed

- Up to 70 objects/minute

- Changeover method

- Tool-free

- Control panel type

- HMI / Touchscreen

- Integration possibilities

- Compatible with existing systems

- Tool-free format changeover

- Quick, easy

- Laminar flow attachment

- Optional

- Filling systems

- Rotary piston pump / Peristaltic pump

- Batch and audit trail protocols

- Flexible implementation