Inline solid-liquid mixer for battery production

In battery production, a critical phase entails mixing solids with liquids. To achieve optimal performance, minimizing agglomerates in the coating masses is vital. This necessitates a homogeneous dispersion of particles in the coating slurry, comprising solvents, binders, and adhesive materials. Nevertheless, traditional procedures continue to face persistent challenges, such as clumping and undissolved powder residues on unwetted tank surfaces.

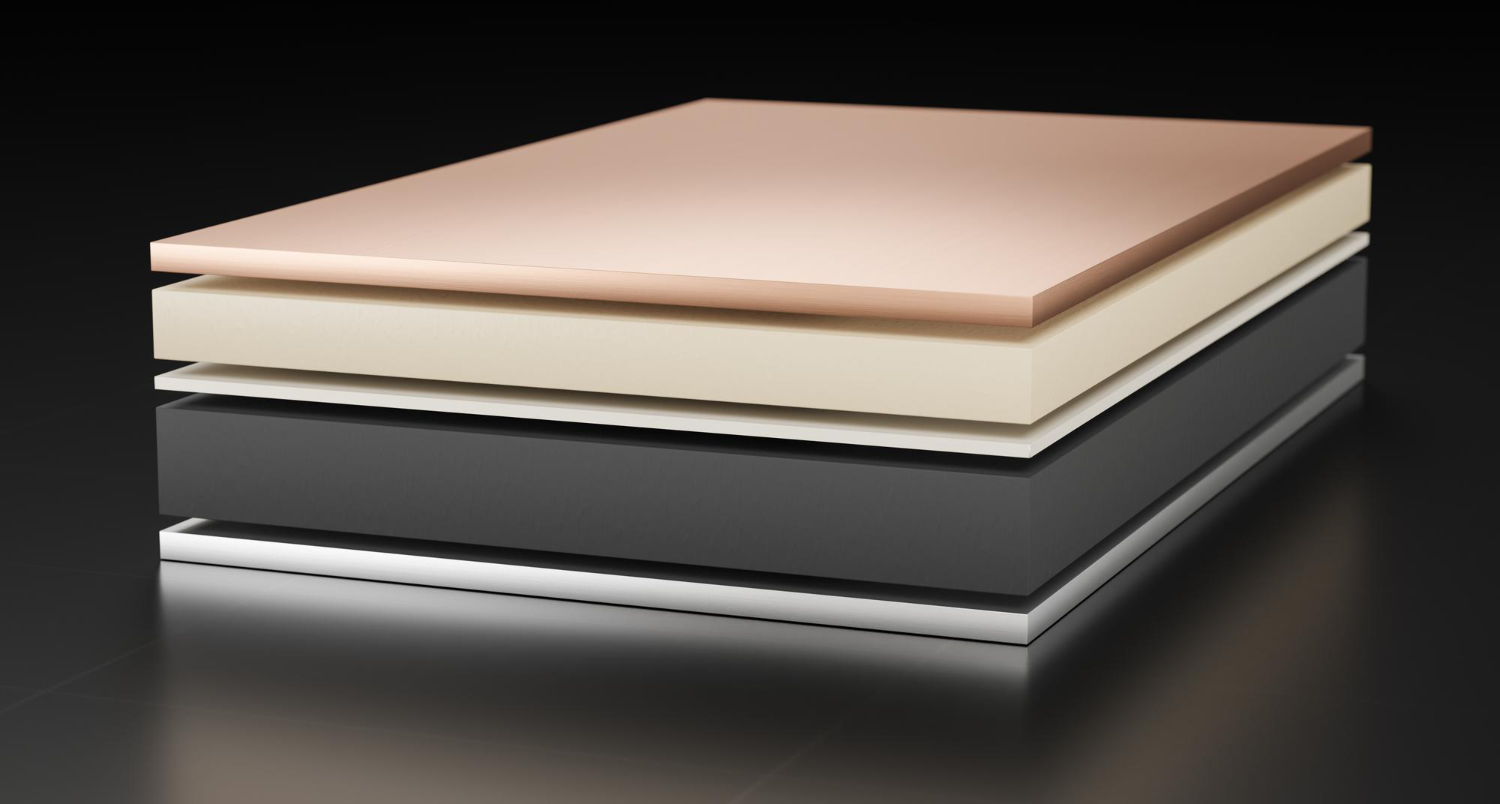

Fully enclosed batch mixing system for fuel cell and battery

The CMX 2000 inline mixer from IKA incorporates powders into liquids in an enclosed and complete system. It mixes the liquid solvents homogeneously with solids ensuring consistent product and dispersion quality with concentrated energy input.

Featuring a dosing feeder for solids and recirculation technology, the solution limits the mixing process to one machine and reduces the potential for emissions.

The multi-level pump is designed to keep high-viscosity materials flowing without leaving deposits in the mixing container. The chemicals are recirculated to ensure consistent blending and prevent the formation of agglomerates in the final mix.

Solid may be fed with a bulk bag unloader, a hopper, sack-emptying boxes, or directly from the bag with a suction lance. The CMX 2000 is available for batch sizes between 2 and 5.000 liters.

Benefits

- Closed process to avoid dust and solvent emissions

- Manufacturing times are significantly reduced

- No need for additional pumps or powder dosing systems

- Prevention of agglomerates

- CIP, GMP, and ATEX-compliant design possible