Piston stroke control for filter press

Enhance your filter press efficiency with a piston stroke control system that reduces cycle times by up to 40%, optimizing capacity and throughput in separation processes.

Reduces Filter Press Cycle Time

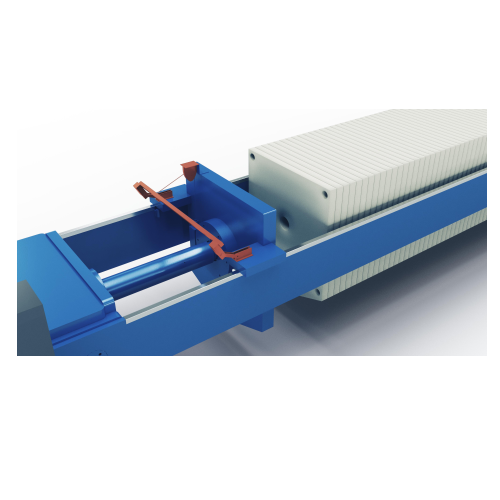

The Metris addIQ piston stroke control from ANDRITZ SEPARATION is designed to enhance the efficiency of filter press operations by reducing cycle times by up to 40%. It shortens the movement range of the cylinder and shifting plate, allowing rapid opening of the plate pack for quicker discharge of the filter cake. This unique capability is particularly beneficial for industries such as chemicals, mining, mineral processing, wastewater treatment, and pulp and paper, where increased capacity and throughput are critical.

Suitable for both sidebar and overhead filter presses, this control system can be easily retrofitted to existing setups. Sidebar filter presses gain from a mechanical stroke shortening device, while overhead presses are equipped with an electronic system for precise control. As a result, your operations can shift seamlessly into high-speed, continuous production modes while handling a diversity of end products, from pharmaceutical powders and mineral slurries to industrial chemicals and food-grade starch.

Energy efficiency and environmental sustainability are key focuses of the Metris addIQ system, ensuring reduced operational costs and a smaller carbon footprint. With the robust design, the equipment integrates effortlessly into existing production lines and supports upstream and downstream processes, maintaining operational continuity and enhancing overall productivity.

Benefits

- Boosts production efficiency by cutting filter press cycle times up to 40%.

- Increases capacity and throughput, maximizing production output.

- Easily integrates into existing systems, allowing for a straightforward retrofit.

- Enhances operational flexibility across diverse industry applications.

- Lowers operational costs through improved energy efficiency.

- Applications

- Separation technologies, Sidebar filter presses, Overhead filter presses

- End products

- Ceramic materials, Mineral slurries, Metallurgical concentrates, Clay suspensions, Food-grade starch, Fruit juice clarification, Industrial chemicals, Pharmaceutical powders

- Steps before

- Slurry preparation, Material mixing, Feeding material to filter press

- Steps after

- Filter cake discharge, Cake drying, Material collection

- Input ingredients

- filter press, plate pack

- Output ingredients

- filter cake, increased capacity

- Market info

- ANDRITZ is known for its expertise in supplying industrial ETO equipment and services, specializing in sectors like pulp and paper, hydropower, and metals. It has a strong reputation for innovation and engineering excellence.

- Cycle Time Reduction

- Up to 40%

- Filter Press Compatibility

- Sidebar and Overhead

- Piston Stroke Control Type

- Mechanical/Electronic

- Automation

- Metris addIQ Control Systems

- Reduction in cycle time

- Up to 40%

- Improvement in capacity

- Increased

- Automation level

- Electronic system / Mechanical device

- Retrofitting capability

- Easy

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Filter press type

- Sidebar/Overhead

- Retrofitting capability

- Easy to retrofit

- Control panel type

- Electronic / Mechanical

- Discharge method

- Shortened piston stroke

- Control system type

- Metris addIQ control systems

- Integration capability

- Easy to retrofit

- Application compatibility

- All makes and models of sidebar and overhead filter presses