Chemical Containment Equipment

chemical containment equipment is crucial for preventing hazardous spills. Discover the best types of chemical containment technology here!

Chemical containment equipment plays a crucial role in ensuring that hazardous materials such as solvents, chemicals, and other dangerous substances are properly contained and do not cause harm to people or the environment. The primary function of chemical containment equipment is to prevent leaks and spills that can happen during storage, handling, and/or transporting.

One of the most popular materials used for containing chemicals is polyethylene. Polyethylene is a durable and flexible material. That can withstand exposure to harsh chemicals and is often used in the construction of spill containment berms. As well as spill pallets, and secondary containment systems.

Secondary containment is an important aspect of spill prevention. It acts as a backup system in case the primary containment fails. OSHA requires secondary containment for most hazardous materials. Including those stored in drum storage facilities. Spill decks, sumps, and spill containment trays are all examples of secondary containment equipment that can help prevent a chemical spill from spreading. In the event of a chemical spill, spill control is critical. A spill kit is a collection of spill containment products and tools designed to quickly and efficiently contain and clean up a chemical spill. These spill kits often contain absorbent materials. As well as gloves, goggles, and other personal protective equipment.

The Environmental Protection Agency (EPA) also mandates Spill Prevention, Control, and Countermeasure (SPCC) plans for facilities that store large quantities of hazardous materials. SPCC plans outline specific spill prevention measures, such as regular inspections of storage containers and equipment, employee training, and emergency response procedures. Chemical containment equipment comes in many shapes and sizes, including spill containment berms, spill pallets, and spill containment trays. These products are specifically designed to contain spills and prevent them from spreading. Thus, making them an essential component of any facility that stores hazardous materials.

Which chemical containment technology do you need?

Intermediate bulk containers for powder and materials handling

Optimize your material handling processes with containers...

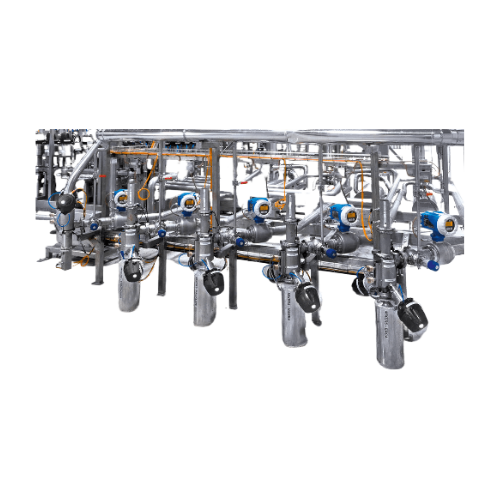

Ion exchange for chloride and potassium removal in kraft mills

Optimize your kraft mill operations by efficiently removi...

Containment solutions for hazardous material processing

Ensure safe and efficient processing of hazardous materials with ...

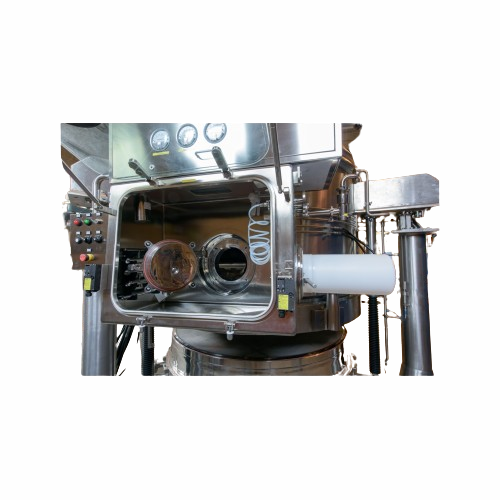

Filter dryer with containment system for hazardous materials

Ensure operator safety and product integrity during hazardo...

Stainless steel drums for powder storage

For high-value powder storage, these stainless steel drums offer reliable containm...

Dust-control sack tip station for industrial loading

Ensure seamless and safe unloading of powders with an integrated dus...

Heavy duty rotary valves for powder handling

Ensure precise material flow and safety in harsh processing environments with...

Quick-clean hygienic rotary valves

Ensure seamless cleaning and minimal downtime in your production line with rotary valves...

Big bag unloader for industrial bulk materials

Efficiently handle bulk materials with this modular unloading system, desig...

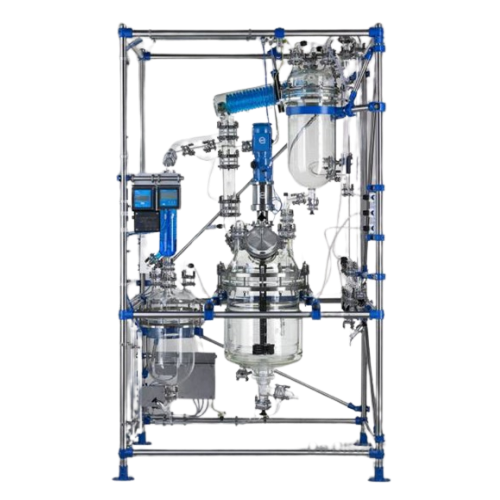

Industrial universal reactor for large-scale chemical synthesis

For chemical producers scaling past laboratory setups, t...

Powder handling drum dock station

Ensure safe and efficient powder transfers with high containment levels, minimizing opera...

Shielded radiochemistry fume hood

Enhance your lab’s safety and efficiency with a fume hood designed for precise hand...

50l stainless steel dual-jacketed reactor for chemical processes

Optimize your laboratory’s efficiency with a dual...

Industrial pressure vessels

Ensure product integrity and regulatory compliance with engineered-to-order pressure vessels, de...

Special chemical plant safety systems

Ensure operational safety and regulatory compliance in chemical processing with advan...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Vacuum conveyors for explosive and inert gas environments

Optimize the safe transfer of hybrid mixtures and fine powders...

Containment system for product loading

Ensure safe handling of hazardous materials with this containment system, designed t...

Containment single-use filter module

Ensure safe handling of high-potency substances and streamline filtration processes wi...

Downflow booths for hazardous material processing

Ensure product integrity and operator safety during hazardous material ...

Sanitary separator for food processing applications

Ensure efficient separation and prevent contamination in food product...

Full flow filtration system for bioprocess applications

Ensure sterile filtration of process liquids and aseptic chemical...

High containment big bag discharge docking system

The discharge of materials demands strict containment, particularly in ...

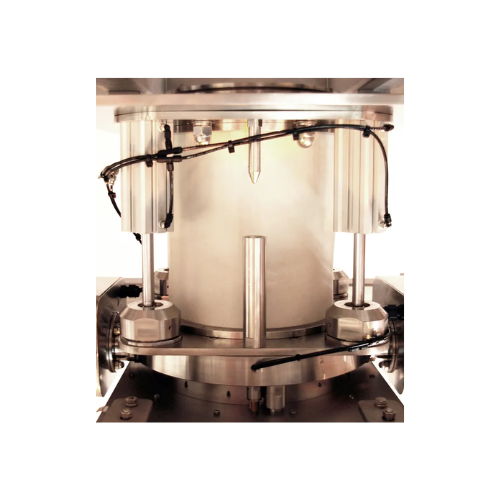

Closed restricted access barrier system

Pharmaceutical production techniques often require isolation of compounds and chemi...

Powder handling system for industrial applications

Overcome powder flow issues and enhance production efficiency with adv...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Silicone dust caps for dust-tight powder transfer

Achieve dust-tight containment and efficient powder transfer with flexi...

Split butterfly valve for sterile powder transfer

Ensure safe and sterile transfer of powders with unparalleled containme...

Hygienic flexible sleeves for food and pharmaceutical use

Say goodbye to contamination risks with this tool-free, quick-...

Cleanroom air filtration unit for pharmaceutical production

Ensure sterile integrity in your manufacturing process with ...

Supercritical Co2 extraction system

Optimize your extraction processes with environmentally friendly and efficient supercri...

Powder conditioning station for high containment applications

Ensure safe and precise handling of hazardous powders with...

Six stage r&d isolator for safe material handling

Ensure optimal operator safety and material containment during complex ...

Mini plant isolator for laboratory protection

Ensure maximum operator safety and product integrity with a versatile isolat...

Isolators for safe Hapi transfer and dispensing

Ensure the safe, precise transfer and dispensing of highly active pharmace...

Dispensing isolator for hazardous substance handling

Ensure maximum operator safety and contamination control when handli...

Laminar flow hood with lead glass for laboratory use

Ensure sterility and precision in high-stakes environments with adva...

Radiochemistry fume hood

Ensure precise containment and filtration during radiochemical processes, safeguarding both operator...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

Powder dispensing funnel

Enhance powder handling accuracy while minimizing product loss with a precision-engineered dispensin...

Automatic docking system for bulk powder handling

Optimize docking precision and ensure seamless alignment in bulk powder...

Transfer valve cleaning for sterility assurance

Ensure seamless cleaning and sterility while maintaining containment integ...

Synthesis gas cooler for partial oxidation of oil or natural gas

Optimize high-temperature gas streams efficiently by em...

Carbon capture membranes for Co2 separation

Efficiently reduce carbon emissions in power plants and industrial operations ...

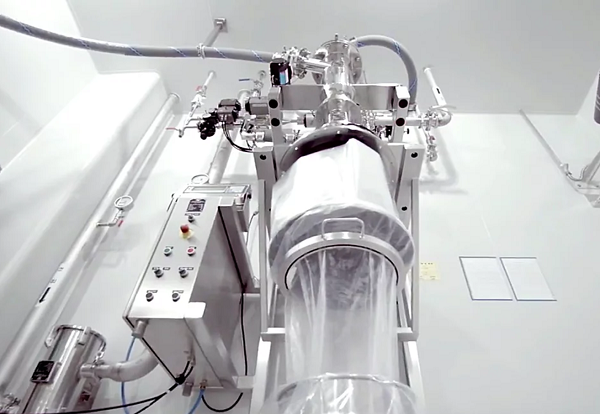

Flexible isolator for aseptic containment

Ensure sterility and safety with a flexible isolator designed for efficient cont...

Cleanroom enclosure system for pharmaceutical and chemical industries

Ensure sterile environments with this customizabl...

High containment isolator for toxic and active drug handling

Ensure safe handling and environmental protection while pro...

Customizable storage tanks for industrial use

Optimize your production with versatile storage tanks designed for precise c...

Product recovery system for hygienic applications

Efficiently reclaim valuable products from your production lines while ...

Fibc emptying stations for powder processing

Streamline your bulk powder handling with single-operator FIBC emptying stati...

Industrial bin vent filter for fine dust particles

Enhance your production line with efficient fine dust filtration to en...

Industrial control cabinets and control stations

Streamline your plant operations with customizable control cabinets and s...

Pressure vessel for hazardous and non-hazardous liquids and gases

Ensure safety and compliance when handling hazardous ...

Flanged round dust collectors for industrial air filtration

Optimize your industrial processes with a dust collection sy...

Membrane pressure relief valve for silo protection

Ensure immediate pressure stabilization in your bulk storage silos wit...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Drum discharge system for bulk material handling

Achieve precise, gentle transfer of sensitive pharmaceuticals and granula...

Supply air filter systems for industrial cleanrooms

Ensure critical air purity and operational safety in sensitive enviro...

Round vibratory separation equipment - bag dump screener system

Enhance your material handling and safety by efficiently...

Refrigerated vacuum cold trap for chemical vapor applications

Efficiently trap corrosive vapors and eliminate the need f...

Fume hood with pipes for chemical laboratories

Ensure maximum safety and efficiency in your laboratory by effectively exha...

Single-use containment valves

From GMP and HSE perspective material transfer is critical for chemical and pharmaceutical for...

Disposable isolator

Pharmaceutical powders need to be contained in the strictest conditions. But handling powders and cleanin...

High containment micronizing isolator

Powder processing for chemical compounds demands product-specific micronizing solutio...

Drum filling system

Pharmaceutical and chemical products may be toxic or prone to contamination from environmental exposure. ...

Drum emptying system

Handling products from the pharmaceutical and chemical industries requires careful attention and extreme...

Production plant for biodiesel

As a biofuel producer, making biodiesel from several types of treated vegetable oils or anima...

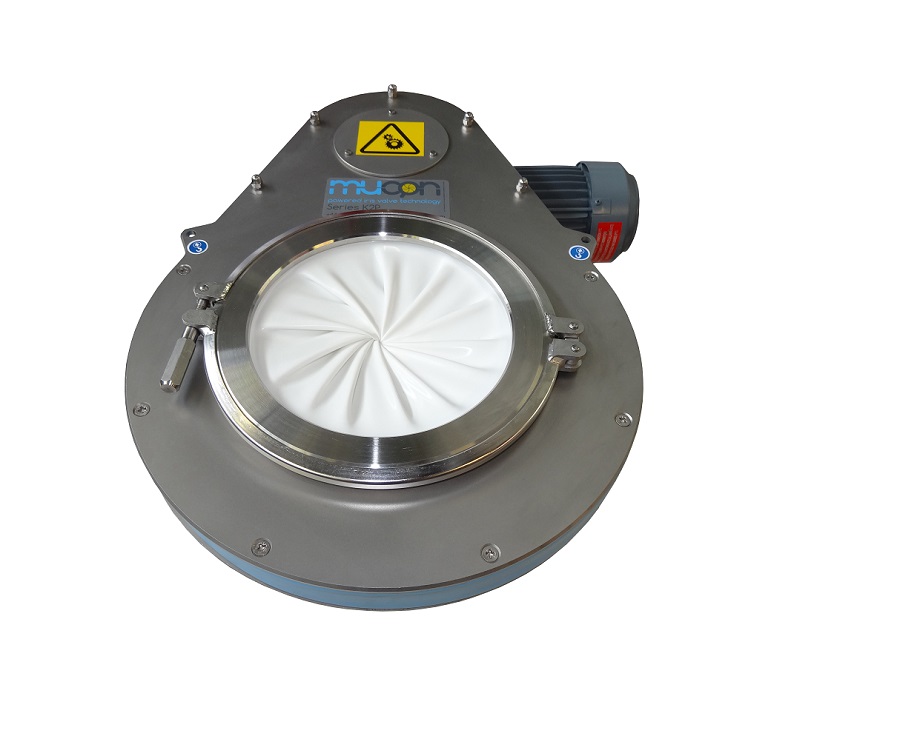

Hygienic automatic iris valve

In automated systems where controlled discharge of powders and bulk solids is required with a ...

Hygienic hand-operated iris valve

Hand-operated valves are required for the walls of clean rooms for glanding around cables...

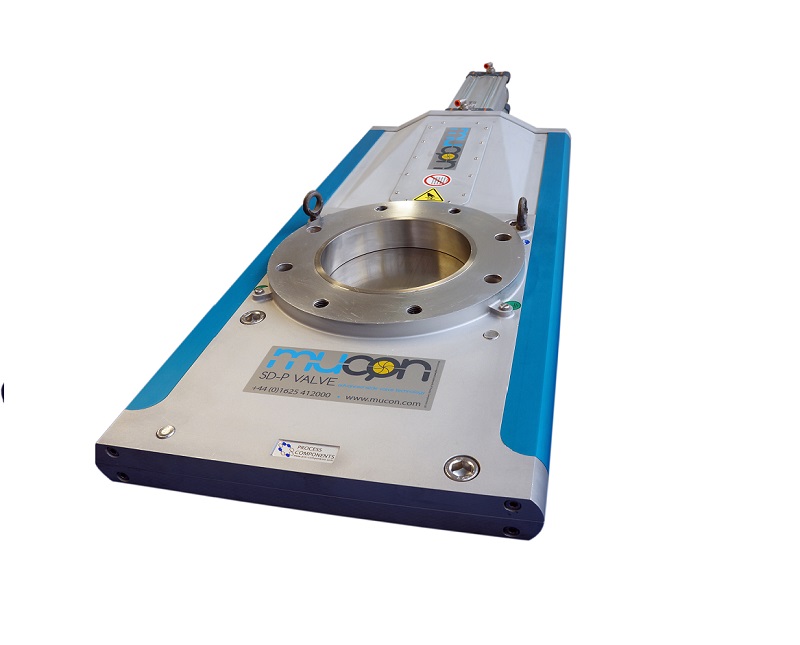

Slide gate valve

In the powder and bulk handling industries, in-line shut off valves are required to provide uninterrupted smo...

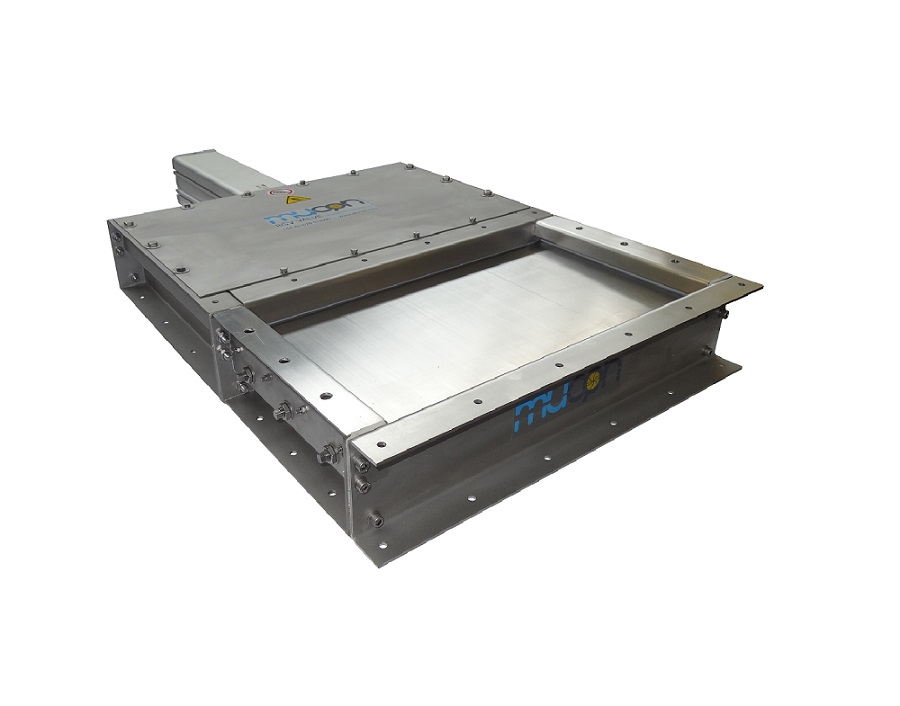

Roller gate valve

In large scale operations, modular and configurable valves are required to isolate and control dry powders,...