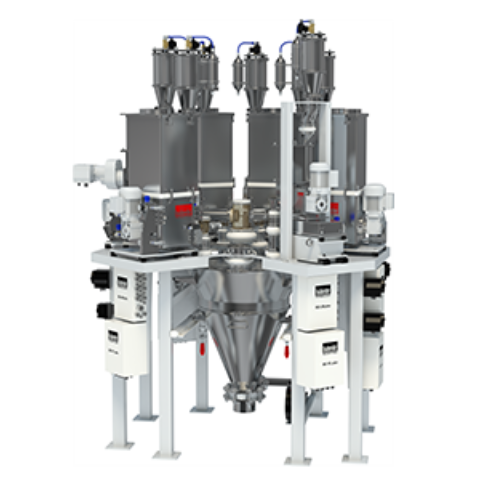

Hopper scale for precision batching

Achieve high batch accuracy with a central weighing hopper engineered for seamless integration into complex production environments, ensuring reliable and precise multi-ingredient batching.

Automates Multi-Ingredient Batching and Weighing

The Hopper Scale from SPS Solids Process Solutions is designed for precision batching to accommodate a range of industries including aquafeed, chemical, and dairy production. Utilizing a central weighing hopper with both volumetric and gravimetric feeding, it ensures high batch accuracy through its Automatic Rate Turndown (A.R.T.) mode. The scale automatically halts feeding upon reaching the target weight, optimizing efficiency in batching operations. Ideal for handling solids, powders, and granules, it integrates seamlessly into existing production lines. Engineered to enhance productivity, it offers customization options to fit specific production needs and complies with industry standards for reliable performance.

Benefits

- Enhances batch precision with automatic ingredient weight adjustments.

- Increases production efficiency by integrating volumetric and gravimetric feeders.

- Supports a wide range of materials, from powders to granules, for versatile application.

- Minimizes material wastage through precise feeding control.

- Adaptable to existing systems, improving manufacturing workflow.

- Applications

- Food, Fine chemical, Feed, Recycling, Nutrition, Detergents, Compounding, Chemical, Pharma, Plastics, Minerals, Masterbatch, Aquafeed, Dairy, Petfood

- End products

- Precision chemicals, Pharmaceutical tablets, Liquid detergents, Snack foods, Processed minerals, Lactose powders, Color masterbatches, Recycled plastic granules, Dry pet food mixes, Fish pellets, Protein supplements, Animal feed pellets, Composite materials, Polymer pellets, Dietary supplements

- Steps before

- Ingredient Handling, Material Preparation, Bulk Storage

- Steps after

- Quality Control, Packaging, Distribution

- Input ingredients

- multiple ingredients, materials for batching

- Output ingredients

- batched materials, weight-adjusted batches

- Market info

- Batch accuracy

- High accuracy (specific value not provided)

- Batch weight control

- Automatic recipe driven

- Weighing method

- Gain-in-weight

- Feeding mode

- Coarse/fine flow or “A.R.T.” mode (“Automatic Rate Turndown”)

- Stop mechanism

- Automatically stops when reaching target weight

- Feeding type

- Volumetric and gravimetric feeders

- Working mechanism

- Automatic recipe driven multiple ingredient gain-in-weight batching

- Integrated steps

- Central weighing hopper with volumetric and gravimetric feeders

- Batch vs. inline flow

- Batch operation

- Automation level

- Automated controller with target weight calculation

- High accuracy mode

- Coarse/fine flow or “A.R.T.” mode

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Hopper shape

- Central weighing

- Feed method

- Volumetric and gravimetric feeders

- Discharge method

- Automatic stop at target weight

- Batch size variability

- Multiple ingredient batching

- Feeder type

- Volumetric and gravimetric

- Weighing method

- Gain-in-weight