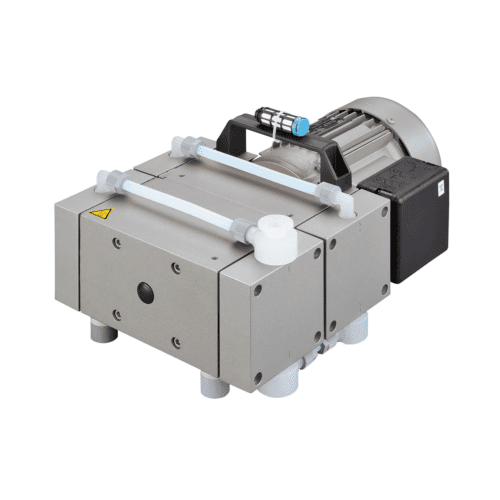

High-capacity oil-free diaphragm vacuum pump

Achieve cleaner operations and reduce maintenance costs with this high-capacity vacuum pump, designed to deliver oil-free, pristine environments essential for precise laboratory and industrial applications.

Generates Clean, Oil-Free Vacuum for Laboratory Applications

The Welch 2052B-01 from Welch ILMVAC is an oil-free diaphragm vacuum pump designed for diverse laboratory and industrial applications. It provides a clean, contaminant-free pumping environment ideal for gas sample cleaning and vacuum filtration. The innovative oil-free design eliminates the risks associated with oil back-streaming, ensuring the purity of samples across pharmaceutical, biotech, chemical, and environmental industries. This model operates at a pumping speed of 2.3 CFM with an ultimate pressure of 1.5 Torr, and is equipped with a KF-16 intake connection for seamless integration into existing systems. With reduced maintenance requirements, including straightforward diaphragm replacement every 6-18 months, it ensures long-term operational efficiency. Certified under UL standards, this pump is ready to deliver high-purity results while maintaining a low cost of ownership.

Benefits

- Ensures sample purity by providing oil-free vacuum operation.

- Minimizes maintenance costs with simple diaphragm replacement.

- Enhances workplace safety and cleanliness by eliminating oil usage.

- Optimizes process integration with a compact design and standard KF-16 connection.

- Certified compliance with UL ensures reliability and industry-standard safety.

- Applications

- Chemical processing, Research and development, Analytical chemistry, Environmental testing, Industrial applications, Vacuum filtration, Gas sample cleaning, Oil-free applications, Laboratory applications

- End products

- Environmentally tested samples, Pure gas samples, Filtered particulate samples, Research-grade chemicals, Oil-free vacuum systems, High-purity analytical samples, Clean laboratory environments, Solvent-free chemical compounds

- Steps before

- Extraction, Remediation, Filtration

- Steps after

- Distillation, Packing

- Input ingredients

- gases

- Output ingredients

- uncontaminated gases, cleaner samples

- Market info

- Precision Extraction Solutions is known for providing innovative, high-quality extraction equipment and solutions for the cannabis industry, specializing in systems that enhance efficiency and safety in extracting cannabinoids and essential oils.

- Pump Type

- Oil-Free, Diaphragm

- Pumping Speed

- 2.3 CFM

- Ultimate Pressure

- 1.5 Torr

- Power

- 120V / 1 ph

- Intake Connection

- KF-16 with 3/8th hose barb on filter

- Dimensions

- L 12.08” x W 9.05” x H 6”

- Weight

- 40.34 lbs

- Pumping Speed

- 7.8 CFM

- Ultimate Pressure

- 6 Torr

- Dimensions

- L 21.25” x W 9.25” x H 12”

- Weight

- 90 lbs

- Pump Type

- Oil-Free, Diaphragm

- Automation level

- Manual

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Oil-free, reducing maintenance needs

- Energy efficiency

- Low energy consumption due to oil-free design

- Corrosive resistance (e.g. acids)

- PTFE compatibility

- Biological compatibility

- Oil-free operations

- Cleanability

- Oil-free, easy to maintain

- Machine Footprint

- L 12.08” x W 9.05” x H 6” (2052B-01)

- L 21.25” x W 9.25” x H 12” (2163B-01)

- Weight

- 40.34 lbs (2052B-01)

- 90 lbs (2163B-01)

- Intake Connection

- KF-16 with 3/8th hose barb on filter

- Oil-Free Operation

- Yes

- Diaphragm Material

- PTFE

- Intake Connection Type

- KF-16 with 3/8th hose barb on filter