Mechanical air separator for uniform fineness

Achieve precise material separation and de-dusting with our air separator, ensuring consistent fineness and efficiency in continuous high-speed operations.

Separates Fine Powders and Granules Efficiently

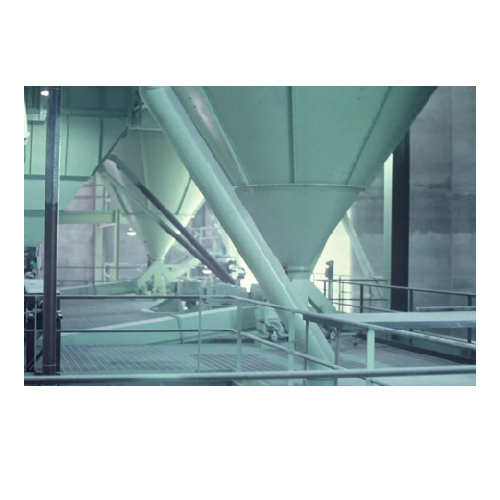

The Raymond® Mechanical Air Separator by Schenck Process is designed for efficient separation and de-dusting of fine powders in continuous operations. This equipment stands out with its unique whizzer blade design that enhances centrifugal action, suitable for both open and closed circuit configurations. Primarily used in cement, chemical, and fertilizer applications, it helps produce consistent end-products such as Portland cement, ammonium nitrate, and more.

The separator efficiently processes up to 99.5% passing 325 mesh, supporting operations in environments demanding precise particle size control. With a robust design, it integrates seamlessly into existing production lines alongside ball, tube, and compartment mills. Engineered for energy efficiency, it circulates material through a closed loop, minimizing wastage and optimizing throughput.

Available with single or double whizzer configurations, the separator can handle the rigorous demands of chemical processing and mineral powder production, offering adaptability with customizable rotor speeds. Maintenance is streamlined due to its durable construction, ensuring longevity and continuous operation with minimal downtime.

Benefits

- Ensures uniform particle size, enhancing product quality in cement and chemical applications.

- Minimizes energy consumption with efficient closed-loop processing.

- Reduces maintenance downtime through durable construction and reliable whizzer blade design.

- Adapts to various production needs with customizable configurations.

- Supports efficient de-dusting, improving environmental compliance in production facilities.

- Applications

- Chemical processing, Dewatering applications, Mineral processing, Masonry cements, Agrichemicals, Raw mix cement, Finished cement, Fertilizers, Cement

- End products

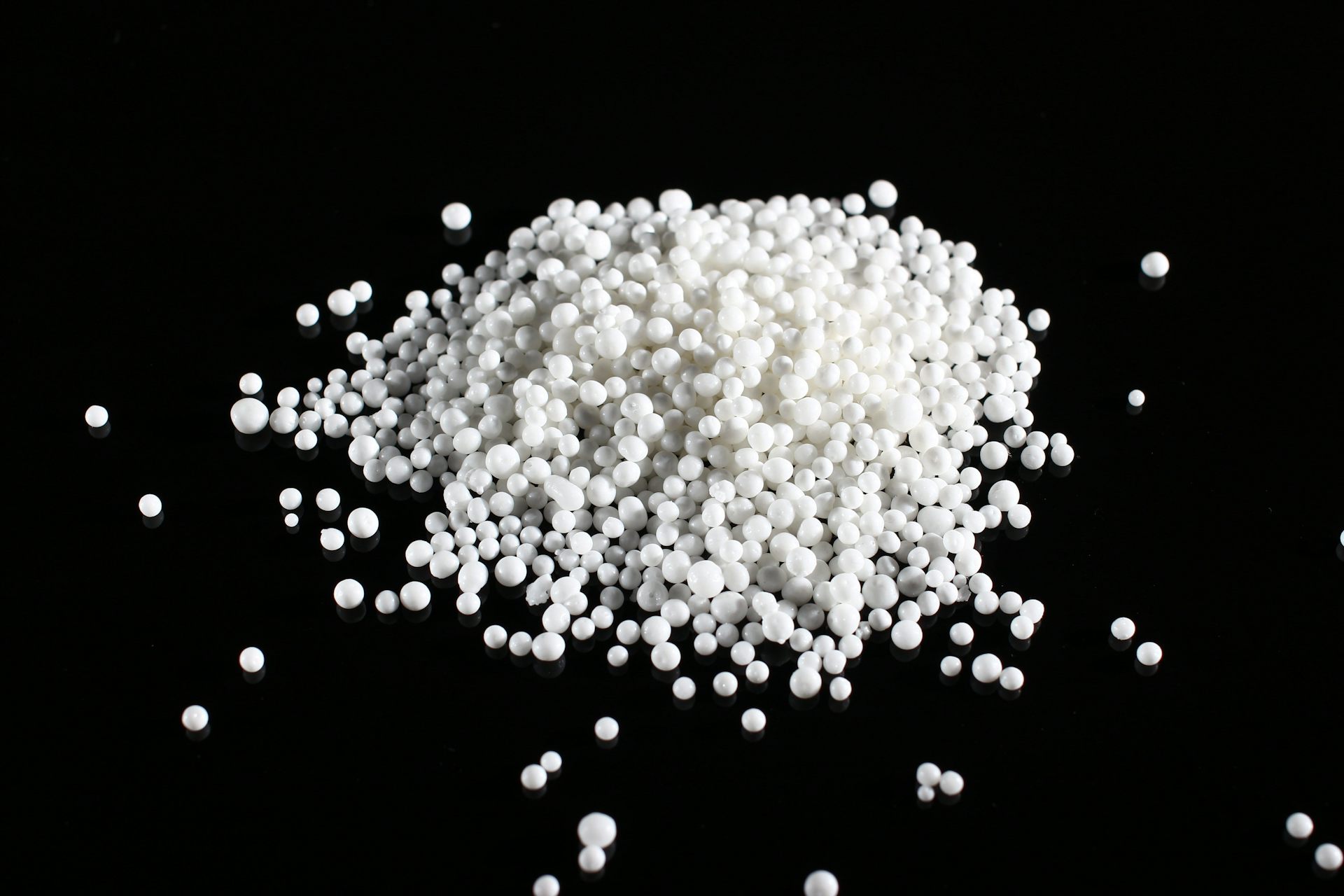

- Triple superphosphate, Cementitious grout, Phosphate rock powder, Calcium carbonate, Ammonium nitrate, Blended cement, Micronized minerals, Hydrated lime, Portland cement, Clinker, Potassium nitrate, Superphosphate, Masonry mortar

- Steps before

- Grinding, Milling, Pulverizing

- Steps after

- Packing, Cooling, De-dusting

- Input ingredients

- raw mix, material, fresh feed

- Output ingredients

- high uniform fineness material, fines, coarse product, finished materials

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Operation Type

- Open/Closed Circuit

- Whizzer Type

- Single/Double

- Mesh Size Passing

- 85-90% passing 200 mesh (Single Whizzer)

- Mesh Size Passing

- 99-99.5% passing 325 mesh (Double Whizzer)

- Fineness Control

- Constant

- Finished Material Fineness

- 0.5-1% R44 microns

- Milling Circuit Types

- Ball/Tube/Compartment Mills

- Product Applications

- De-dusting, Raw Mix Cement, Finished Cement Circuits

- Blaine Values

- 2800-6000 Blaine (Masonry Cements)

- Working mechanism

- Single/double whizzer blades

- Separation process

- Centrifugal action

- Circuit operation

- Open/Closed circuit

- Material fineness

- High uniform

- De-dusting capability

- Yes

- Drying and cooling

- Available

- Fines rejection

- Positive

- Circulating load

- Constant in closed circuit

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Separator type

- Single or Double whizzer

- Feed/discharge method

- Open or closed circuit

- Cooling option

- Available

- Drying option

- Available

- Circuit operation

- Open / Closed

- Integration with mills

- Ball mill / Tube mill / Compartment mill