Chemical Filtration Equipment

Find production equipment for filtrating chemicals, and connect with with a global network of leading technology providers.

Poor filtration of chemicals quickly snowballs into production problems down the stream. If not properly filtered, materials can develop sub-products that degrade the quality of the final chemical. Chemical filtration equipment isolates and purifies the compounds from undesired particulate or pollutants. Technologies apply various filtering techniques such as pressing, vacuum, or pressure leaf to refine the final product into a high-grade chemical.

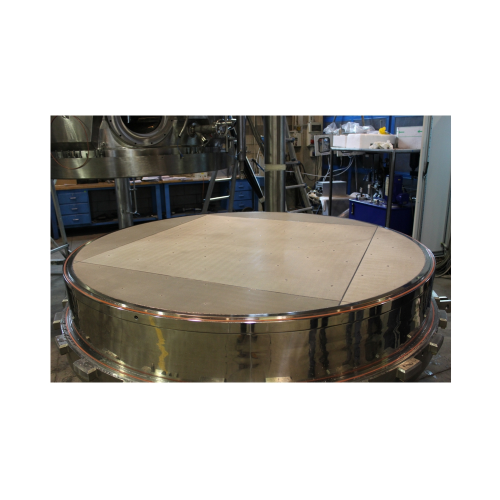

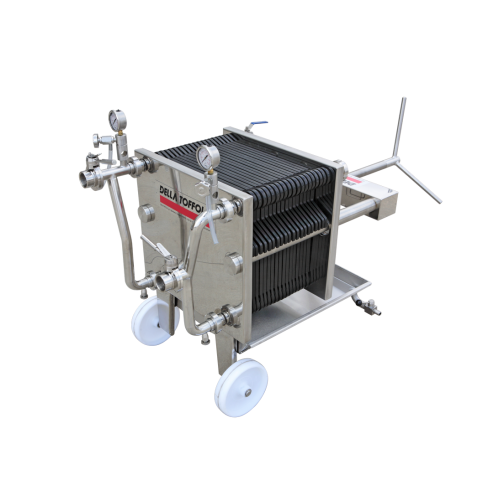

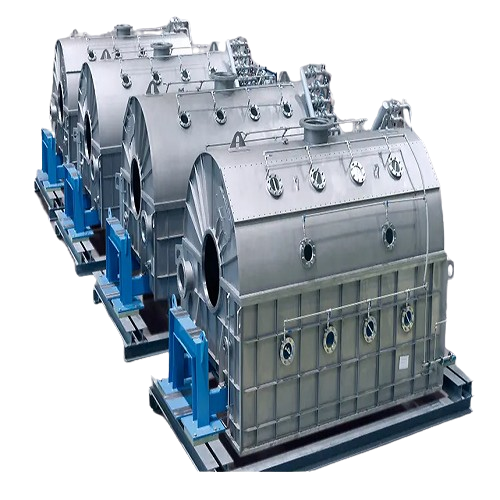

Separate solid impurities from chemicals with a filter press

One of the earliest liquid-solid separation technologies was the filter press. The filtration technique is especially suitable for removing solid particulates and emulsions from chemical solutions.

A press is divided into chambers enclosed by filtration cloths. The pump distributes the feed slurry evenly and applies pressure to push the solids against the cloths, discharging the filtrate at the bottom of the machine. The solids build up into a dewatered cake and can be removed from the plates. The filter cloths are cleaned in a dedicated washer and ready for the next cycle.

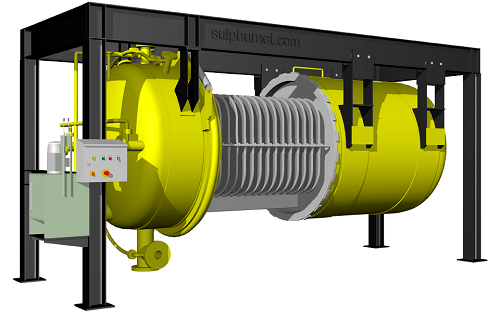

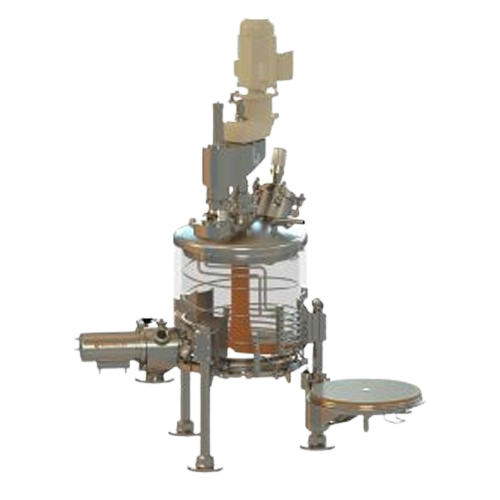

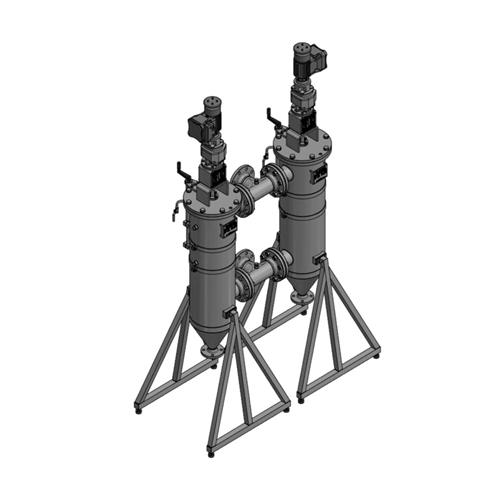

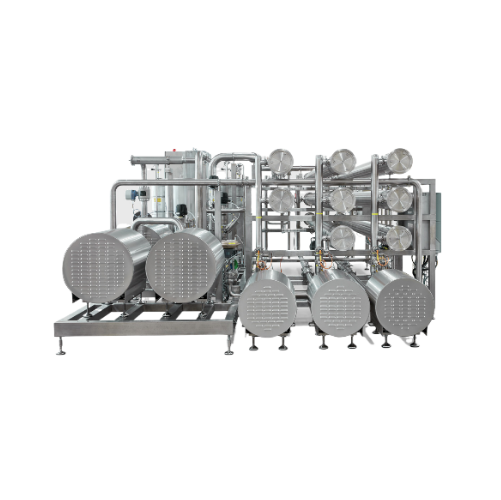

Filter semi-solid chemicals with pressure leaf equipment

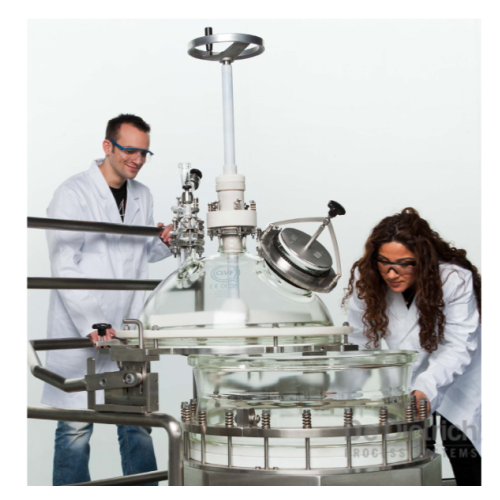

Slurries such as organic salts, pectin, or liquid sulfur are turned into solids before further processing. Pressure leaf filters separate the impurities and form the material into a cake.

The liquid or semi-liquid is pumped into a vessel lined with a series of filters of varying mesh sizes. The impurities are let through, leaving behind a purified substance. In case of hazardous chemicals, the filtration technology sluices the material off the leaves by spraying water and pumping out the discharge. The filtration equipment can be configured either vertically or horizontally.

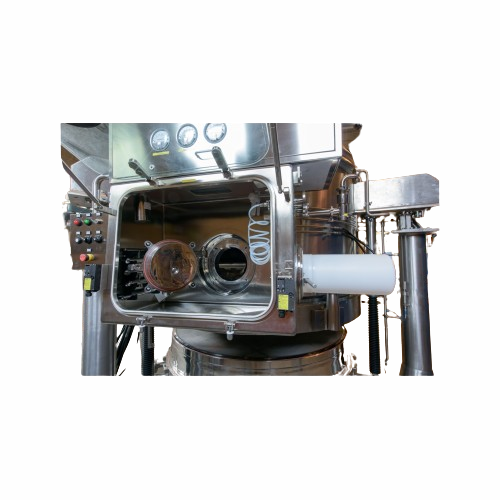

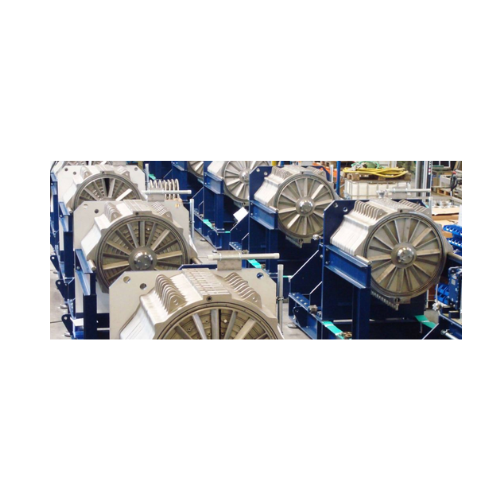

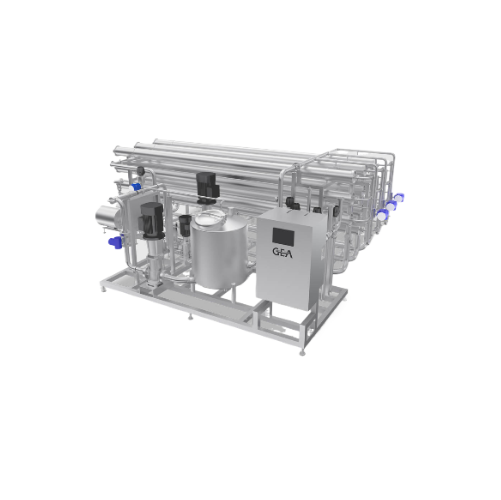

Achieve higher filtration rates with batch centrifugal systems

Sensitive products such as pharmaceutical ingredients or cell cultures demand ultrafiltration methods. Centrifuge technology can achieve such a level of fineness, but this category of chemical filtration equipment covers a broad range.

Traditional batch systems are based on the peeler method, with a basket holding the solids rotating in a closed unit. A newer technique known as the siphon peeler applies vacuum pressure through a siphon chamber to increase the rate of filtration.

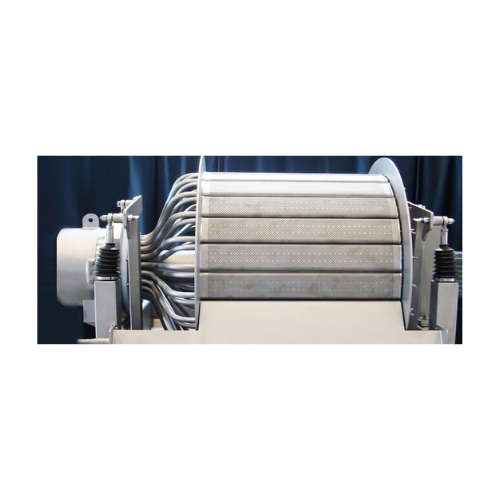

Sliding discharge equipment allows continuous chemical filtering

Centrifugal equipment for chemical filtration can also be adapted for continuous processing. A primary technology in this application is the sliding discharge. There are several variants of this method, but they all have a conical basket that moves the filtrate outwards into the discharge.

Sliding discharge centrifuges are designed according to the fiction angle of the specific product, so they cannot be used to filter multiple chemicals.

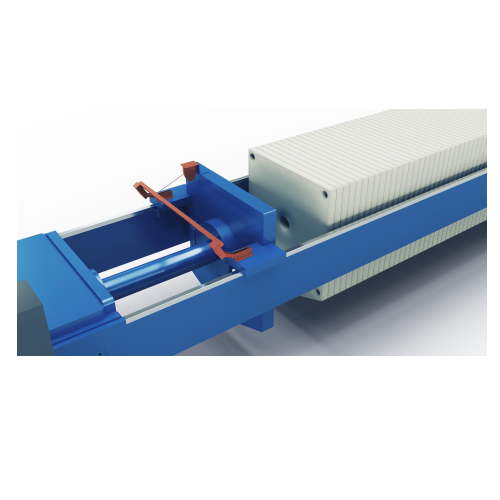

Use a belt filter press for large capacities

Processing high volumes of chemicals put a heavy burden on filtration equipment. The belt filter press is a family of industrial technologies designed for excess capacities.

The material is pressed against two filter cloths driven by a system of rollers. The pressure on the feed squeezes the filtrate out into the discharge unit. The solids are moved into the collection bin as the belts roll on.

Which chemical filtration technology do you need?

Separators for biochemicals

Achieve precise separation and purification of complex biochemical mixtures with self-cleaning c...

Net-gas medicine storage cabinet for volatile chemicals

Ensure safe and efficient storage of volatile chemical agents wit...

Industrial leaf filter for chemicals

In recent years the removal of sulphur has received increasing attention because of sa...

Pilot-Scale Centrifuges for Process Development

Scaling up from laboratory experiments to industrial production requires r...

batch centrifuge for solid-liquid separation

Achieve precise solid-liquid separation in high-demand environments with a ma...

Continuous filtering centrifuge for solid-liquid separation

Effortlessly separate and filter crystalline or fibrous susp...

Pilot scale nutsche filter dryer for solid-liquid separation

Achieve maximum product recovery and consistent quality wit...

Nutsche filter dryer system for small scale batches

Efficiently tackle filtration and drying challenges with a compact, m...

Vibrating control screeners for high volume screening and sifting

Ensure precise material separation with a solution de...

Beer production filtration system

Enhance your beverage production with cutting-edge filtration systems designed to maintai...

Filtration system for Cip cleaning in food production

Optimize your cleaning processes with a state-of-the-art filtration...

Self-cleaning filter for industrial and hygienic applications

Ensure continuous operation and minimal waste in your liqu...

Stainless cartridge filters for industrial applications

Achieve precise fine filtration and maximize efficiency in liquid...

Filter dryer with containment system for hazardous materials

Ensure operator safety and product integrity during hazardo...

Pharmaceutical filter dryer

Achieve precise moisture control and efficient drying of sensitive materials with this advanced ...

Multilayer filter plates for pharmaceutical and chemical applications

Achieve efficient filtration and separation in yo...

Pilot unit filter dryer for laboratory applications

Efficiently manage filtration and drying processes with precise tempe...

Sterilizable filter dryer for pharmaceutical applications

Ensure full sterility and efficient moisture removal in critic...

Vertical pilot plant centrifuge for chemical industry

Optimize your lab and pilot plant operations with this mobile centr...

Inverting filter centrifuge for difficult-to-filter products

Designed for challenging filtration tasks, this centrifuge ...

Inverting filter centrifuge for high-potent Api products

Achieve optimal separation and reduce residual moisture with pre...

Top discharge centrifuge for pharmaceutical production

Optimize your product yield and quality with precise filtration an...

Chemical and pharmaceutical solid-liquid separation pilot plant

Optimize your pilot-scale production of pharmaceuticals ...

Glass lined columns for chemical plants

Optimize your chemical processing with glass-lined columns, designed to ensure maxi...

Industrial vibrating sifters for granular material separation

Achieve precise particle separation and ensure product pur...

Crossflow filter for clarified and unclarified wines

Optimize your filtration process with ceramic membrane technology th...

Glass nutsche filter for fine chemical and pharmaceutical filtration

For precise separation and filtration in R&D ...

Pilot scale filter-dryer for pharmaceutical and chemical batches

Streamline small-batch production with a mobile filter-...

Microwave-enhanced filter dryer for chemical and pharmaceutical applications

Achieve rapid drying and efficient separa...

Static nutsche filters for liquid-solid separation

Achieve efficient separation of solids from liquids with precise contr...

Regenerative vacuum blower for pneumatic conveying

Optimize your material handling with a compact regenerative vacuum blo...

Shielded radiochemistry fume hood

Enhance your lab’s safety and efficiency with a fume hood designed for precise hand...

Laboratory crossflow filtration test system

Efficiently test and determine optimal filtration parameters with this portabl...

Pressure drum filter for fine-grained products

Achieve exceptional precision in fine particles processing with this pressu...

Industrial drum vacuum filter for filtration and washing

Efficiently manage filtration, washing, and dewatering tasks wit...

Agitated nutsche filter for solid-liquid separation

Ensure high-purity solid-liquid separation with minimized contaminati...

Agitated nutsche filter dryer for solid-liquid separation

Achieve high-purity solid-liquid separation with optimized thr...

Automatable benchtop agitated nutsche filter-dryer

Effortlessly integrate seamless solid-liquid separation into your labo...

Nutsche filter-dryer for solid-liquid separation

Ensure precise moisture control and efficient solid-liquid separation for...

Screen scroll centrifuge for flexible dewatering

Ensure maximum uptime and consistent dewatering performance amidst variab...

Piston stroke control for filter press

Enhance your filter press efficiency with a piston stroke control system that reduce...

Pressure drum filter for ultra fine-grained products

When traditional filtration methods fall short, ensure ultra-fine pr...

Continuous filtration centrifuge for solid-liquid separation

Achieve precise solid-liquid separation with high efficienc...

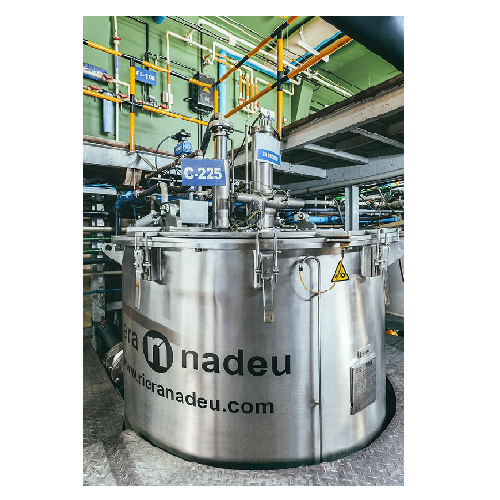

300l stainless steel dual-jacketed reactor for winterization

Enhance your extract processing with precision temperature ...

Stainless steel crystallization reactor 100l

Optimize your crystallization and formulation processes with precision-contro...

50l jacketed glass reactor for synthetic reactions

Achieve precise control over chemical reactions and material synthesis...

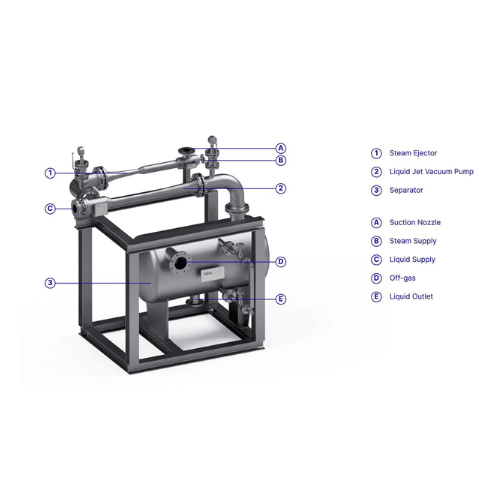

Steam jet liquid ejector vacuum system for chemical applications

Achieve reliable vacuum under challenging conditions wi...

Industrial self-cleaning air filter for pneumatic lines

Ensure clean air and efficient dust removal in your pneumatic tra...

Aerosol separator system for industrial emission control

Enhance your emission control measures with our aerosol separato...

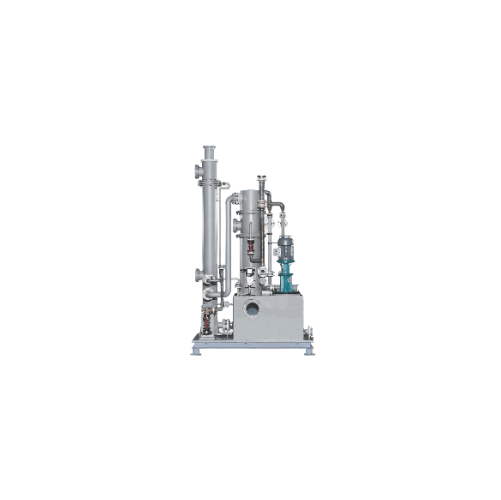

Melt crystallization for high purity chemical products

Achieve ultra-pure products with minimal energy by integrating mel...

Cyclone separator for industrial dust separation

Optimize your dust separation process with this cyclone separator, design...

Special chemical plant safety systems

Ensure operational safety and regulatory compliance in chemical processing with advan...

Bulk solids discharging and loading solution

Optimize your bulk material handling with equipment that ensures efficient an...

Atex certified flanged round dust collectors

Designed for potentially explosive environments, these flanged round dust col...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Containment system for product loading

Ensure safe handling of hazardous materials with this containment system, designed t...

Containment single-use filter module

Ensure safe handling of high-potency substances and streamline filtration processes wi...

Lab scale round separator for particle classification

Optimize lab-scale processes with this compact separator, ideal for...

Sanitary separator for food processing applications

Ensure efficient separation and prevent contamination in food product...

Deionization systems for ultra-pure water production

Achieve unmatched water purity by removing dissolved ions, crucial f...

Industrial process water treatment system

Optimize your industrial water management with technology that purifies and recl...

Industrial water treatment for cooling circuits

Optimize your cooling systems and reduce resource consumption with advance...

Full flow filtration system for bioprocess applications

Ensure sterile filtration of process liquids and aseptic chemical...

Industrial grinding mill replacement parts service

Optimize production efficiency with high-precision grinding solutions ...

Optimal maintenance solution for industrial weighfeeders

Streamline your processing operations with a solution that minim...

Self-cleaning candle filtration system

Separating solids from liquids by filtration requires frequent cleaning or replaceme...

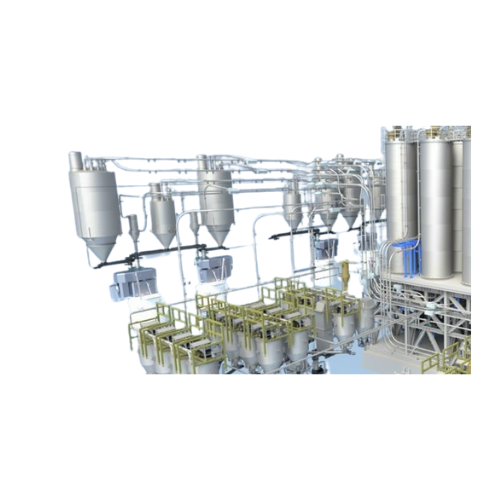

Refining plant for vegetable oil and animal fats

The main problems arising from refining process of vegetable oil and anim...

Industrial liquid filtration system

Systems for the filtration of liquids with suspended solid contents can be challenging ...

Tumbler sieve for classifying and dedusting granular materials

For the classification of delicate granular material, scr...

Multifrequency sieve for separation of difficult particles

Separating particles in difficult-to-process materials for pr...

Horizontal vacuum dryer with eccentric agitator

Conventional dryers are inefficient and can lead to significant mechanical...

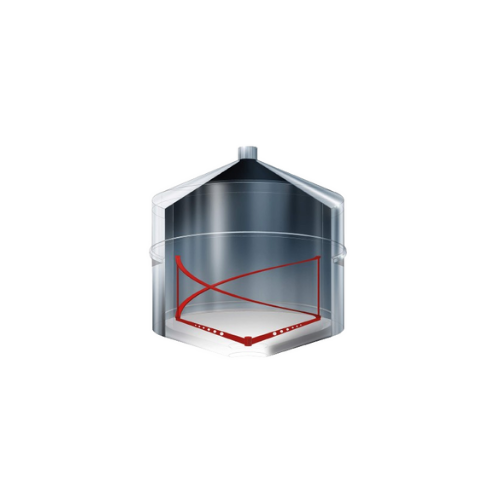

Vertical pressure leaf filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to many in...

Horizontal pressure leaf filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to many ...

Horizontal plate scavenger filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to ma...

Vertical batch centrifuge for solid-liquid separation

Optimize your solid-liquid separation process with high-speed centr...

Horizontal batch centrifuge for chemical industry

Optimize your solid-liquid separation with a centrifuge designed for pr...

Agitated nutsche filter dryers for chemical synthesis

Enhance your production efficiency by integrating a system that com...

Laboratory nutsche filter dryer for solid-liquid separation

Optimize your lab processes with a versatile benchtop filter...

Explosion-proof rotary vane vacuum pump

Ensure safety and efficiency in flammable environments with this explosion-proof va...

Laboratory chemically resistant dry scroll vacuum pump

Ensure efficient handling of aggressive or corrosive substances wi...

2-stage rotary vane vacuum pump for laboratory applications

Ensure reliable and efficient vacuum conditions for distilla...

Syringe filters for liquid and gas samples

Ensure particle-free liquid and gas samples with high-precision filtration, ide...

Industrial water treatment system

Ensure your beverage production maintains optimal purity and taste with tailored water tr...

High-containment tablet dedusting solution

Ensure pharmaceutical tablets and capsules meet strict dust control and safety ...

Continuous acid purification for aluminum anodizing

Eliminate costly impurities from your process acids and ensure consis...

Ultrapure water demineralizer for critical boilers

Achieve high-purity water production with minimal chemical usage and a...

Industrial sieving solution for solid materials

Effortlessly separate impurities and adjust particle size for optimal prod...

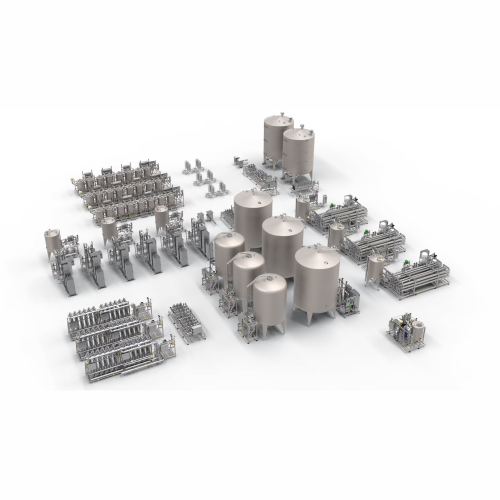

Industrial skids for liquid processing

Efficiently manage large-scale liquid and solid processing in your production line w...

Turnkey resin synthesis plant system

Streamline resin production with a comprehensive turnkey system designed to efficientl...

Purified water generation system for pharma applications

Ensure consistent purity in your therapeutics production with a ...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Fruit and vegetable juice filtration

Ensure superior clarity and purity in your juice production with advanced filtration s...

Self-cleaning automatic filters for industrial liquids

Ensure reliable filtration of high-contamination liquids while min...

Magnetic bag filter unit for heating and cooling systems

Efficiently remove magnetic and non-magnetic particles to enhanc...

Chemical filter dryer for fine chemical production

When processing chemical intermediates, precise filtration and drying ...

Pilot plant filter dryer for small scale production

Optimize filtration and drying processes in your pilot plant with a v...

Top discharge centrifuge for chemical manufacturing

Achieve precise filtration and separation with top discharge centrifu...

Vertical peeler centrifuge for chemical industry

Maximize throughput in continuous chemical processes with a versatile ver...

Pharmaceutical horizontal peeler centrifuge

Optimize product consistency and purity with precise separation and filtration...

Vacuum belt filters for solid-liquid separation

Ensure high-efficiency solid-liquid separation and maximize filtrate recov...

Vacuum table filters for liquid-solid separation

Optimize your liquid-solid separation with vacuum table filters, designed...

Din standard glass-lined reactors

Streamline your chemical reactions with these DIN standard glass-lined reactors, designed...

Industrial continuous distillation system

Enhance product purity and efficiency with a robust continuous distillation syst...

Laboratory filter-reactor for chemical synthesis and extraction

Optimize your chemical processes with a versatile filter...

Lab nutsche filter for small scale filtration

Efficiently manage filtration and drying needs in fine chemical and pharmace...

Centrifugal disc filter for solid-liquid separation

Optimize solid-liquid separation in your processing line with an adva...

Nutsche filter dryer for pharmaceutical and chemical industries

Achieve precise filtration and efficient drying in one s...

Vacuum pneumatic conveying for infant nutrition

Ensure efficient handling of delicate powders with a versatile vacuum pneu...

Sack tipping station for dust-free bulk material handling

Efficiently manage bulk materials while minimizing dust exposu...

Cleanroom air filtration unit for pharmaceutical production

Ensure sterile integrity in your manufacturing process with ...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Central water purification system for laboratories

Ensure consistent supply of ultrapure water essential for critical lab...

Evaporative gas cooling system for industrial gases

Optimize exhaust gas management with precision cooling and conditioni...

Thermal process plants for liquid treatment

Achieve precision thermal processing with systems designed to optimize the hea...

Ceramic ultrafiltration for treating oily emulsions

Optimize your oily emulsion treatment process with advanced ceramic u...

Crossflow filtration with ceramic membranes for wines

Enhance filtration efficiency and durability with ceramic membranes...

Rotary vacuum filters for wine and lees filtration

Achieve high-precision liquid filtration and separation with continuou...

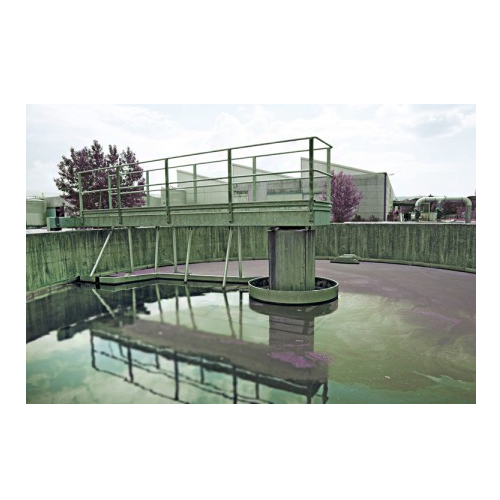

Chemical-physical treatment plants for water treatment

Optimize your water and wastewater treatment processes with system...

Rotary vacuum filters for wine and beverage filtration

Efficiently filter and clarify wines, juices, and industrial fluid...

Industrial plate filter press for winemaking

Efficiently separate liquids from solids to recover valuable liquid component...

Industrial sheet filters for diverse liquid filtration applications

Achieve precise liquid filtration with adaptable sh...

Biological water treatment systems

Maximize efficiency in water treatment with advanced biological systems designed to seam...

Industrial crossflow filters with ceramic membranes

Achieve precise filtration with robust ceramic membranes, ideal for h...

Ceramic membrane crossflow filters for wine clarification

Enhance filtration efficiency with ceramic membranes offering ...

Reverse osmosis system for wine production

Enhance wine quality and versatility with advanced reverse osmosis systems that...

Sheet filters for wine and beer filtration

Enhance your filtration process with reliable sheet filters designed for high-q...

Agitated nutsche filter and filter-dryer for pharmaceuticals

Ensure precise filtration, washing, and drying of sensitive...

Oil neutralizing technology for chemical refining

Achieve optimal purity and yield in oil processing with precise control...

Dispensing isolator for hazardous substance handling

Ensure maximum operator safety and contamination control when handli...

Laminar flow hood with lead glass for laboratory use

Ensure sterility and precision in high-stakes environments with adva...

Radiochemistry fume hood

Ensure precise containment and filtration during radiochemical processes, safeguarding both operator...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

Industrial filter centrifuges for high solids content processing

Optimize processing of high-solid slurries with efficie...

Industrial exhaust air treatment for food processing

Effectively eliminate volatile organic compounds and odors while max...

Automatic cross-flow filter for wine

Experience enhanced filtration efficiency with reduced waste, as this cross-flow filte...

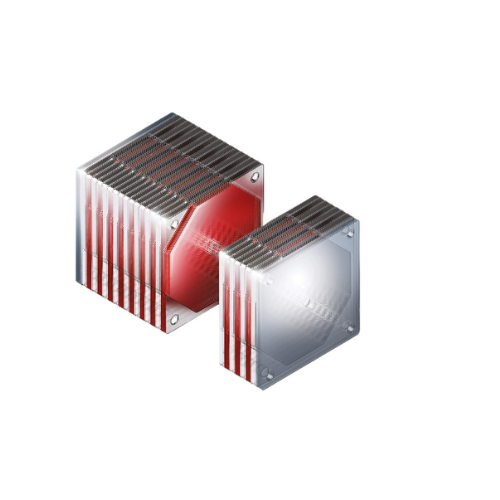

Filtration testing for spinnable polymer purity

Ensure the purity of your thermoplastic melts and spinnable polymers by ac...

Ethylene recovery unit for ethylene oxide and glycol production

Recover valuable ethylene monomer efficiently from cycle...

Organic solvent nanofiltration for liquid separation

Optimize your process streams with solvent recovery that minimizes e...

Pan filter for coarse-grained suspension filtration

Optimize your filtration process with a horizontal pan filter, design...

Crossflow filtration with sieve filter for difficult suspensions

Achieve precise separation and recovery in challenging ...

Compact filtration device for laboratory and field use

Achieve precise filtration with minimal sample sizes for rapid ana...

Vacuum filtration for large suspension volumes

For high-volume slurry filtration, streamline your process with a rotary di...

Bioreactors for cell culture processes

Efficiently cultivate sensitive cell lines with customizable bioreactors designed to...

Integrated pickup station for bagged products and big bags

Streamline the handling and transition of bulk materials with...

Bag feeding hopper for bulk solids

Optimize your material handling with a robust feeding hopper that seamlessly integrates ...

Full-membrane water for injection (wfi) generation system

Ensure consistent high-quality injections by integrating real-...

Flexible isolator for aseptic containment

Ensure sterility and safety with a flexible isolator designed for efficient cont...

High containment isolator for toxic and active drug handling

Ensure safe handling and environmental protection while pro...

Industrial ion exchange system for chemical purification

Ensure precise ion removal and high-purity output in your produc...

Vacuum drum filter for solid/liquid separation

Optimize your solid/liquid separation process with a versatile vacuum drum ...

Advanced vacuum and pressure drum filters for high filtration rates

Optimize filtration and separation processes with h...

Horizontal peeler centrifuge for filtration

Optimize your batch processing with a centrifuge designed for high-speed, effi...

Multipurpose membrane filtration system for pilot testing

Optimize your pilot-scale processes with a versatile filtratio...

Dual-jacketed reactor for decarboxylation processes

Streamline your decarboxylation process with a dual-jacketed reactor ...

20l jacketed glass reactor for controlled chemical reactions

Optimize your chemical synthesis with precise temperature c...

Industrial water filtration and clarification systems

Enhance your production’s purity and quality with advanced fi...

Single-stage centrifugal pump for heavy-duty applications

Optimize fluid handling with a high-efficiency centrifugal pum...

Cyclone filter for pneumatic conveying systems

Efficiently separate and filter airborne dust in pneumatic conveying lines,...

Self-cleaning silo filter

Ensure purity and compliance by trapping dust effectively during silo loading, while maintaining c...

Cyclone tank for dust separation in production lines

Optimize your production line with efficient dust separation, ensuri...

Industrial vibrating sieve for powder and lump separation

Ensure precise separation of powders and lumps with this oscil...

Lean phase pressure conveying for powder handling

Effortlessly transport and manage powdered materials with lean phase pr...

Lean phase vacuum conveying system for powder handling

Efficiently transport and separate powders and granules with preci...

Cip recovery system with membrane filtration

Reduce chemical waste and operating costs by recovering over 90% of spent cau...

Condensate polisher for industrial water reuse

Transform waste streams into high-quality water, ready for reuse in diverse...

Membrane filtration pilot units for process optimization

Optimize your process parameters and achieve precise product spe...

Custom-designed membrane filtration systems for industrial applications

Optimize your production with advanced membrane...

Oil purification system for industrial applications

Enhance oil quality and prolong machinery life with our unique filtra...

Dry sorption system for Sox removal

Optimize your emission control with a dry sorption system designed to efficiently remov...

Heavy metal removal system for industrial flue gas

Effectively remove harmful heavy metals from industrial emissions whil...

Industrial bag filter for gas cleaning

Efficiently manage industrial emissions with advanced low-pressure, high-volume bag ...

Compact and laboratory gas scrubbers for chemical emission control

For efficient gas treatment and emission control in ...

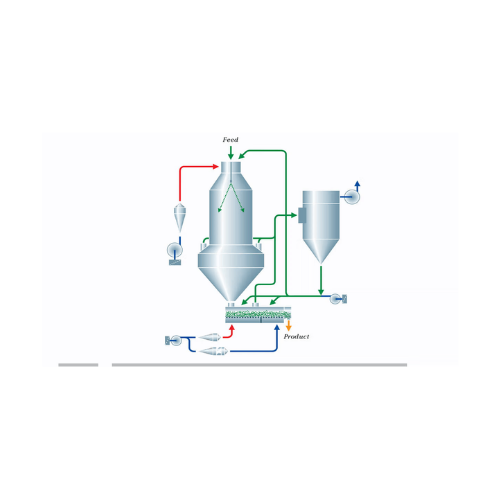

Spray drying solution for uniform powder production

Achieve seamless transformation of liquid feeds into uniform, free-fl...

Membrane mash filter for brewing

Optimize your brewing process with advanced membrane filtration, ensuring maximum yield and...

Efficient mash agitator for breweries

Enhance your mashing process with an agitator designed to optimize heat transfer and ...

Lauter tun for enhanced lautering efficiency and yields

Achieve faster lautering and higher yields with optimized spargin...

Continuous mash filtration system for breweries

Optimize your production line with continuous mash filtration that revolut...

Traditionally welded silos for constrained installation sites

Ideal for facilities with limited space, these traditional...

Automated process controllers for industrial plants

Enhance your production line’s efficiency and adaptability with...

Negative pressure bin vent filter for dust control

Ensure optimal air quality and operational safety by effectively captu...

Negative pressure filter for fine dust particles

Ensure efficient air purification and dust collection in your production ...

Bin vent filter with anti-static filter cartridges

Optimize your production line’s air quality by removing fine dus...

Industrial bin vent filter for fine dust particles

Enhance your production line with efficient fine dust filtration to en...

Bin vent filter for dust control in modular systems

Optimize your production line by efficiently controlling dust and fin...

Dispersion paint production systems

Achieve 100% color accuracy and flexible production with our advanced system, ensuring ...

Continuous pneumatic silo air filtering system

Ensure clean and efficient pneumatically conveyed materials by integrating ...

Ultrafiltration and reverse osmosis for beverage industry

Optimize water treatment with combined ultrafiltration and rev...

Manure treatment system for livestock breeding

Optimize waste-to-value processes with advanced systems designed to efficie...

Bulk solids conveying systems

Efficiently move and manage bulk materials with precision and reliability, ensuring seamless i...

Pneumatic conveying system for bulk solids

Ensure efficient and dust-free transport of bulk materials with a pneumatic con...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

Flanged round dust collectors for industrial air filtration

Optimize your industrial processes with a dust collection sy...

Silo venting filters for dust filtration

Achieve efficient dust control and optimal air quality in your concrete production...

Silo overfilling safety system

Ensure safe silo filling with our system that prevents overfilling and excess pressurization,...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Bag rip-and-tip dump stations for bag emptying

Efficiently manage bag emptying operations with advanced dust containment a...

Big-bag unloading station for bulk materials

Facilitate seamless integration into your production line with efficient bulk...

Continuous vacuum conveyors for material flow control

Ensure consistent material transfer and reduce downtime in your pro...

Supply air filter systems for industrial cleanrooms

Ensure critical air purity and operational safety in sensitive enviro...

Jet filter for industrial air purification

For facilities grappling with dust and pollutant control, enhancing air quality...

Industrial dust collection system

Optimize your process by efficiently capturing and removing airborne dust particles, ensu...

Universal motion rectangular separator for pulp and paper

Achieve precise motion adjustments with a versatile separator ...

Centrifugal sifter for efficient particle separation

Enhance your material throughput by efficiently separating particles...

Multi-motion rectangular separator

Solve screen blinding effortlessly with an innovative system that combines elliptical an...

Round motion separator for dry and wet screening

Optimize your production line with an efficient solution for precise scre...

Quickchange systems for vibratory separator screen changes

Streamline your production with a system that enables rapid s...

Dual-motion rectangular separator for pulp and paper industry

Optimize your production line with a versatile separation ...

Round vibratory separation for various industrial applications

Ensure accurate material separation with a robust solutio...

Industrial stainless steel filters and strainers

Optimize your liquid processing with precision filtration and straining, ...

Dust filter for loss-in-weight feeder refill

Optimize your feeder operations by effectively filtering displaced air and mi...

Physical water treatment for industrial applications

Enhance your water treatment process by efficiently removing contami...

Vacuum belt filter for sludge and suspension filtration

Optimize your production line with efficient filtration and dewat...

Industrial water recirculation treatment system

Optimize your resource management with an advanced water recycling and tre...

Automated dissolution testing system for 16 vessels

Maximize your laboratory throughput by conducting parallel dissolutio...

Fume hood with pipes for chemical laboratories

Ensure maximum safety and efficiency in your laboratory by effectively exha...

Ductless fume hood for medium chemistry experiments

Eliminate the need for cumbersome air duct installations while ensuri...

Paint mixing scale for high precision and reliability

Optimize paint mixing operations with high-precision scale systems,...

Cannabis nanoemulsification system

Transform your cannabis extracts into fast-acting, shelf-stable products with advanced n...

Pharmaceutical horizontal batch centrifuge

Ensure unparalleled product purity and operational efficiency with a centrifuge...

Glycerine manufacturing plant

Glycerol or glycerin is the major by-product generated in the biodiesel production process. Bu...

Self-cleaning filter for sulphur

If you are a small-scale business, the cleaning of moving parts in a traditional filtration...

Vibrating sieve for liquid solid separation

Many industrial processes require the efficient separation of solids from a sl...

Belt filter press

When a saturated slurry or sludge must be dehydrated in a continuous process municipal waste water treatmen...

High yield filter press

When a saturated slurry or sludge must be dehydrated with high yield results mining and other heavy i...

Vacuum drum filter

Manufacturer’s in all fields need peace of mind that their filtration process is efficient and relia...

Side bar filter press

Production of dry cakes is required in a variety of industries and robust, low-cost side bar filtration...

Overhead filter press

To name just a few of the myriad applications for overhead filter presses: industrial mineral industrie...

Filter pressure leaf

From chemical processing, to energy production, to edible oils production, product quality is often depe...