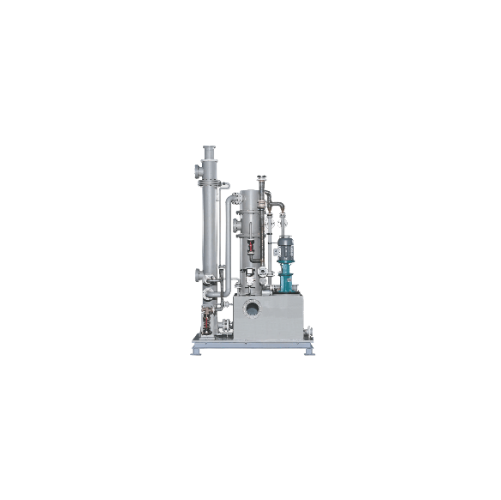

Aerosol separator system for industrial emission control

Enhance your emission control measures with our aerosol separator system, designed to efficiently capture and remove fine particles and aerosols, ensuring cleaner exhaust outputs and compliance with environmental regulations.

Separates Aerosols and Particulates from Exhaust Streams

The Aerosol Separator System from GEA is engineered to effectively remove fine particulate matter and aerosols from industrial exhaust streams. Utilizing a blend of inertial and coalescing separation techniques, this system ensures continuous removal and collection of airborne contaminants. Ideal for applications like power generation and chemical processing, it targets emissions reduction, promoting cleaner exhaust and compliance with environmental standards.

Operating with a processing capacity of up to 200,000 m³/h exhaust gas, it features advanced integration capabilities including PLC control and real-time monitoring for enhanced operation and efficiency. Constructed from durable materials available in various grades, this system withstands corrosive environments and high-temperature operations, suitable for industries handling aggressive chemicals and high particulate loads. Additionally, with easy-to-maintain design elements and available CIP systems, it minimizes downtime and maintenance costs.

GEA’s Aerosol Separator System can be customized with options of filter media and nozzle configurations, catering to specific process demands. It meets rigorous compliance standards for emission control, making it a reliable choice for ensuring high purity levels in diverse operating conditions.

Benefits

- Enhances regulatory compliance by achieving precise aerosol and particulate removal.

- Minimizes operational expenses through energy-efficient separation processes.

- Adapts to diverse industrial applications with customizable material and filter options.

- Maintains high production uptime with continuous operation and low maintenance requirements.

- Supports environmental sustainability efforts by significantly reducing emissions.

- Applications

- Chemical processing, Heavy metal removal, Steel production, Flue gas treatment, Food processing, Emission control, Pharmaceutical manufacturing, Environmental control, Power generation

- End products

- Steel, Clean exhaust emissions, Fine chemicals, Dried food powders, Reduced carbon monoxide emissions, Purified flue gases, Reduced heavy metal emissions, Tablets, Electricity

- Steps before

- Grindinging, Pre-cleaning, Pre-filtration

- Steps after

- Captured material disposal, Emissions monitoring, Sterilization

- Input ingredients

- aerosols, fine solid particles, liquid droplets, exhaust gas, CO-laden gases

- Output ingredients

- cleaned gas, separated solid particles, removed aerosols, recovered gases, heavy metal reduced flue gas

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Particle separation

- Defined separation

- Reliability

- High reliability

- Maintenance

- Little maintenance

- Application flexibility

- Wide area, flexible combination

- Exhaust gas power range

- up to 200, 000 m³/h

- Aerosol separation method

- Inertial separation

- Filter type

- Ceramic candle / Bag filter

- Working mechanism

- Inertial separation

- Integrated steps

- Coalescing stage

- CIP/SIP

- CIP 121°C / SIP 135°C

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- Available in all materials

- Cleanability

- High

- Density/particle size

- Suitable for various densities and sizes

- Material selection

- Available in all materials

- System integration

- Can be flexibly combined and extended

- Application range

- Wide area of application