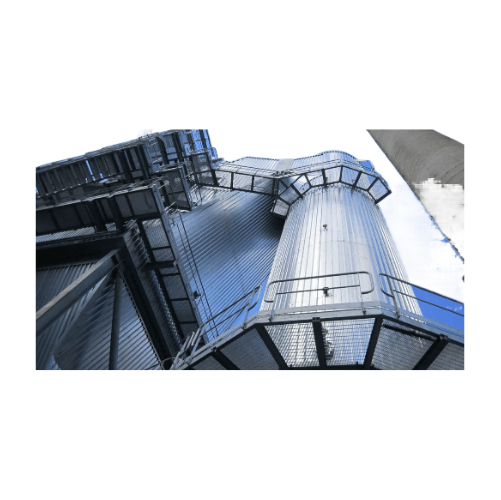

Dry sorption system for Sox removal

Optimize your emission control with a dry sorption system designed to efficiently remove SOx and heavy metals from flue gases, ensuring compliance with stringent environmental standards while operating continuously in demanding industrial environments.

Reduces Acid Gas Emissions in Flue Gas

The Dry Sorption System with Entrained Flow Reactor from GEA is engineered to tackle the complex challenge of flue gas treatment, particularly in fossil-fuelled power plants, waste incinerators, and industrial installations. This system specializes in reducing acid gases—such as SOx—through the injection of dry absorbents like hydrated lime or sodium bicarbonate into the entrained flow reactor, where they chemically react with exhaust gases. The multi-step process culminates in the removal of reaction by-products and particulate matter via downstream equipment like electrostatic precipitators or baghouse filters.

Designed for continuous operation, this system excels in integrating seamlessly into existing emission control lines, ensuring compliance with stringent environmental regulations. With its low CAPEX requirements and small operational footprint, it leverages efficient recirculation and discharge processes to transform pollutants into environmentally manageable compounds such as sulfate compounds and metal oxides. GEA’s system can accommodate various dry reagents, providing flexibility in treating diverse flue gas compositions while maintaining high efficiency.

Benefits

- Ensures regulatory compliance with efficient SOx and pollutant removal.

- Minimizes operational costs through low CAPEX investment and small footprint.

- Offers flexibility with multiple dry reagents for varied gas compositions.

- Enhances maintenance efficiency with reusable dry reaction by-products.

- Operates continuously for seamless integration into existing emission control systems.

- Applications

- Emission control systems, Waste incinerators, Flue gas treatment, Power plants, Industrial installations

- End products

- Sulfate compounds, Calcium carbonate residue, Fly ash, Captured heavy metals, Nacl (sodium chloride), Metal oxides

- Steps before

- Absorbent preparation, Dosing, Reagent injection

- Steps after

- Particulate removal, Reaction product recycling, Product discharge

- Input ingredients

- dry alkaline mineral, flue gas stream, hydrated lime, calcium hydroxide, trona, sodium bicarbonate

- Output ingredients

- acidic gas, organic compounds, heavy metals, sorption reaction products, SOx, furnace dust

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- SOx Removal Efficiency

- Up to 70%

- Reagent Form

- Dry

- Reagent Types

- Hydrated Lime, Trona, Sodium Bicarbonate

- Footprint

- Small

- Particulate Removal Device

- Baghouse Filter, Electrostatic Precipitator, Candle Filter

- Working mechanism

- Entrained flow reactor with dry sorbent injection

- Sorbent type

- Hydrated lime, trona, sodium bicarbonate

- Sorbent form

- Dry powder

- Removal type

- Particulate matter control (baghouse, ESP, filter)

- Recycling

- Dry reaction products can be recycled

- Footprint

- Small

- Automation level

- Potentially PLC/SCADA controlled

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Small footprint equipment

- Reagent form

- Dry powder

- Reagent flexibility

- Hydrated lime, trona, sodium bicarbonate

- Process integration

- Entrained Flow Reactor integration

- Footprint

- Small footprint equipment

- Recycling capability

- Recycled dry reaction products