Vibrating control screeners for high volume screening and sifting

Ensure precise material separation with a solution designed for high throughput in complex production environments, enabling seamless integration and consistent screening of powders, granules, and liquids.

Screens and Separates Solids from Liquids

The GKM Vibrating Control Screeners from Kemutec are designed for high-volume control and safety screening of both dry and wet materials, making them indispensable for sectors like food, pharmaceuticals, and chemicals. These screeners stand out due to their robust construction, capable of handling up to 200,000 kg/h, and modular design, allowing seamless integration into production lines such as conveyor belts and vibrating feeders. Operating through a three-dimensional vibratory action, they ensure effective separation and screening of fine powders and granules, while also facilitating liquid-solid separation.

Available in models KTS-V2 and KTS-VS2, these screeners can be configured with one or two decks, offering up to three product fractions with mesh sizes down to 100 microns. Built with stainless steel options (304L, 316L) for enhanced corrosion resistance, they comply with GMP, FDA, and ATEX certifications, ensuring suitability for stringent applications. The energy-efficient design, featuring a low-maintenance motor, reduces operational costs. Maintenance is streamlined with easy dismantling and cleaning capabilities, supported by patented ultrasonic cleaning technology to prevent screen blinding.

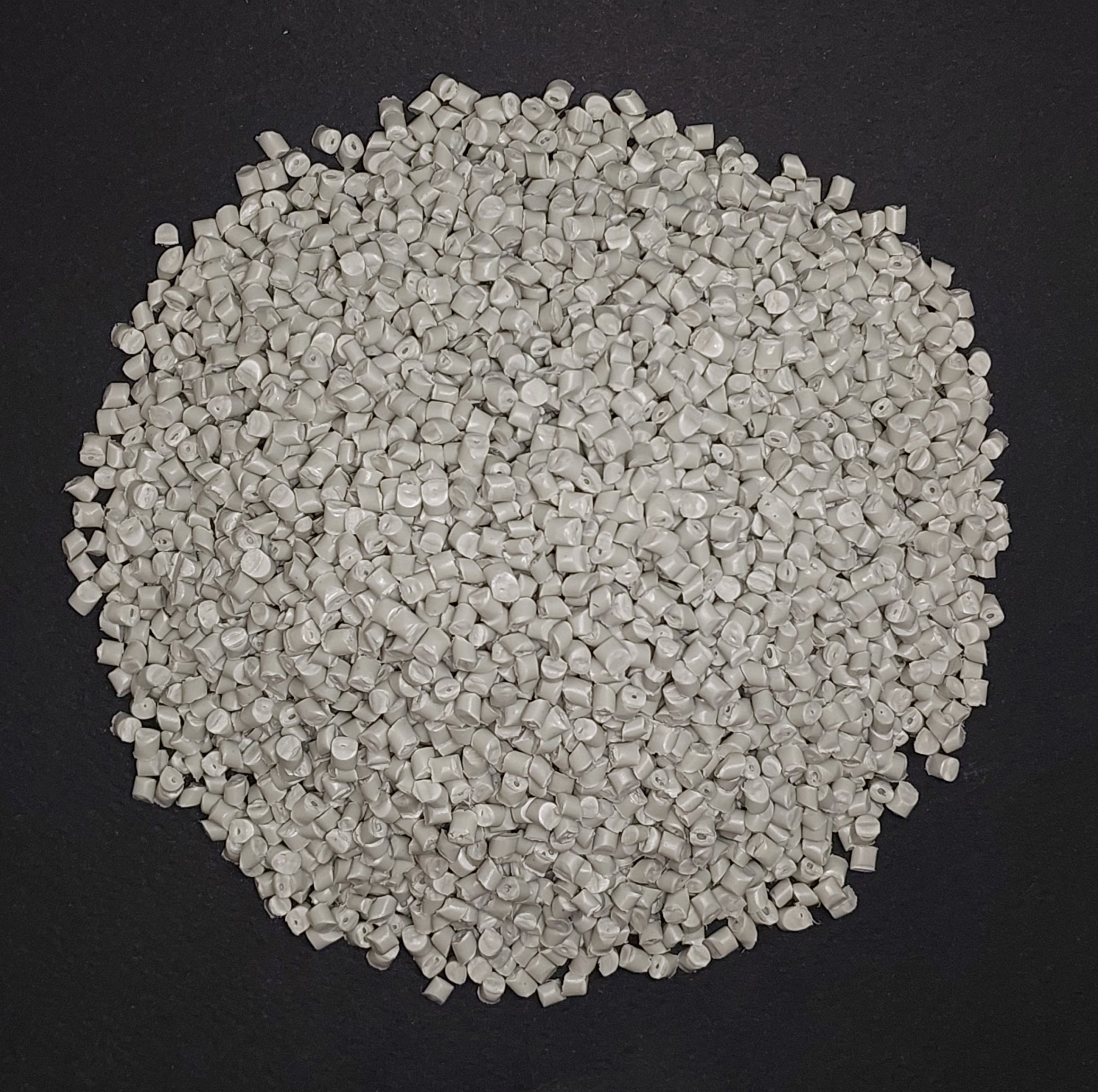

These control screeners, customizable to individual requirements, support high-speed operations and continuous process integration, making them ideal for efficient screening of milk powders, APIs, plastic pellets, and more.

Benefits

- Ensures high product quality by reliably screening and separating up to three fractions per operation.

- Minimizes operational downtime with easy-to-maintain and quick-clean design features.

- Reduces energy costs with efficient motor technology, supporting 24/7 operation.

- Complies with GMP, FDA, and ATEX standards, ensuring regulatory adherence across industries.

- Seamlessly integrates into existing production lines, enhancing flexibility and scalability.

- Applications

- Chemicals, Animal feed, Powder coatings, Pet food, Performance materials, Food products, Minerals, Pharmaceutical ingredients

- End products

- Polyethylene pellets, Polypropylene granules, Active pharmaceutical ingredients (apis), Fish meal, Milk powder, Epoxy powder coatings, Pet kibbles, Fertilizers, Calcium carbonate

- Steps before

- Grinding, Loading, Mixing, Drying

- Steps after

- Bagging, Packing, Filling, Coating

- Input ingredients

- dry products, wet products, dry dusty products, powdered materials, granular materials, milk powders, pharmaceutical ingredients, performance materials, plastics, chemicals, powder coatings, minerals

- Output ingredients

- fine particles, liquid-solid separation, three fractions of material, separated coarse material

- Market info

- Kemutec is known for its expertise in manufacturing industrial powder processing equipment, including sifters, mills, and mixers, tailored to meet specific customer needs. They are reputed for delivering high-quality, reliable engineered-to-order solutions.

- Capacity

- 1 kg/h to 200, 000 kg/h

- Mesh openings

- 100 microns to 20 mm

- Screen movement

- 3-dimensional

- Amplitude

- 4 – 8 mm

- Acceleration

- 4 – 6 g

- Speed range (Dry products)

- 1000/1500 min-1 at 50Hz

- Speed range (Wet products)

- 3000 min-1 at 50Hz

- Model sizes

- 450 – 2000 mm diameter

- Motor power

- 0.19 kW to 1.60 kW

- Materials

- 304(L) and 316(L) Stainless steel

- Surface roughness

- , lt

- 0.4 microns

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- PLC

- Cleaning method

- Easy dismantling and cleaning

- Changeover time

- Minimal, due to fast screen changes

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless Steel 304/316

- Density/particle size

- 200 – 10, 000 grams/liter

- 1 micron up to 20 mm

- ATEX certification

- Zone 20D – Zone 1G

- Machine footprint

- 450 – 2000 mm diameter

- Number of decks

- 1 or 2 decks per machine

- Screen size

- Meshes down to 100 microns

- Construction material

- 304(L) and 316 (L) Stainless steel or 430 FERR

- Surface finish

- Brushed, ground, mirror, electro-polished or ViwateQ

- Discharge method

- Center discharge of fine particles

- Control panel type

- Modular screen assembly

- Screen movement

- 3-dimensional, set to product

- Mesh size

- Down to 100 microns

- Model sizes

- 450 to 2000 mm diameter

- Screen movement

- 3-dimensional

- Discharge method

- Extremely fast center discharge of fine particles