Fruit and vegetable juice filtration

Ensure superior clarity and purity in your juice production with advanced filtration systems that seamlessly integrate into your existing lines, reducing downtime and operational costs while meeting stringent safety standards.

Filters and Purifies Liquid Products

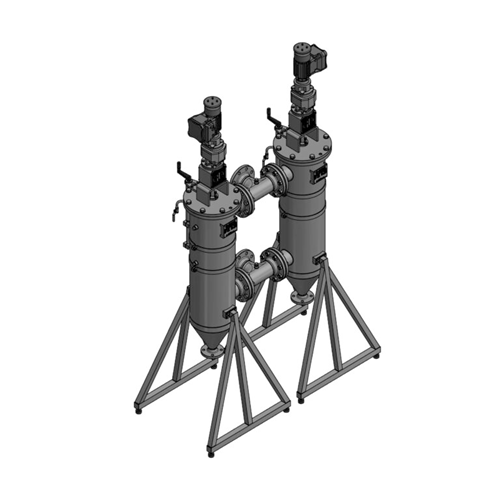

The Auto-line® MLR Series from HiFlux Filtration A/S offers an innovative solution for beverage and food industries, employing self-cleaning technology to maintain uninterrupted filtration of liquid products. Designed to handle everything from fruit juices to dairy drinks, these filters efficiently remove particulates, enhancing clarity and safety. With a robust throughput capacity and continuous operation, the system ensures high productivity levels. Integrating seamlessly with existing production lines, it features PLC-controlled automation for precise operation and remote monitoring. Built with corrosion-resistant materials, the filters offer durability in harsh processing environments, meeting stringent food safety and hygiene standards. Easy to maintain, the system includes a CIP (Clean-In-Place) setup, minimizing contamination risks and downtime. Tailored to fit specific process requirements, customization options are available to optimize performance precisely to your production needs.

Benefits

- Minimizes operational downtime with self-cleaning functionality.

- Enhances product quality by ensuring particle-free liquids.

- Reduces labor costs through automated PLC-controlled processes.

- Complies with stringent food safety and hygiene standards.

- Adapts to a wide range of viscosities, enhancing process flexibility.

- Applications

- Food, Fat and oil, Recycling, Beverage, Paint and coatings, Water processing, Chemicals and polymers, Dairy, Pharmaceuticals

- End products

- Smoothies, Olive oil, Sunflower oil, Syrup, Pharmaceutical solutions, Salad dressing, Paint emulsions, Food-grade chemicals, Polymer solutions, Soy milk, Condiments, Recycled water, Wastewater treatment output, Bottled purified water, Vegetable juice, Carbonated soft drinks, Dairy drinks, Fruit juice

- Steps before

- Grinding, Juice Extraction, Mixing, Homogenization

- Steps after

- Sterilization, Pasteurization, Bottling, Labeling

- Input ingredients

- fruit juice, vegetable juice, particulates, high viscosity liquids

- Output ingredients

- clear juice, pure juice, filtered juice, particulate-free juice

- Market info

- HiFlux Filtration is known for designing and manufacturing high-quality, custom-engineered filtration solutions for industrial applications, renowned for their innovative technology, reliability, and expertise in handling challenging filtration tasks across various industries.

- Filtration type

- Self-cleaning

- Automation

- Automatic

- Capacity

- High Particle Load

- Versatility with Viscosities

- Wide range

- Continuous Filtration

- Operates without interruption

- Reduction of Product Loss

- Minimized

- Working Mechanism

- Automatic Liquid Filtration

- Integrated Steps

- Continuous Filtration Process

- Automation Level

- Self-Cleaning Technology

- Batch vs. Inline Flow

- Inline Continuous

- CIP Principles

- Hygienic Design for Automatic Cleaning

- Changeover Time

- Minimal due to Seamless Integration

- Energy Efficiency

- Low Operational Costs

- Customization Options

- Flexible Filtration Grades

- Versatility with Viscosities

- Wide Range Handling

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Compact, fits existing production lines

- System Design

- Self-cleaning, hygienic design

- Material

- Stainless steel suitable for acidic juices

- Control Panel Type

- PLC-controlled automation

- Feed/Discharge Method

- Inline processing

- Enclosure

- Fully enclosed system

- Control panel type

- PLC / HMI

- Integration possibilities

- Seamless integration with existing production line

- Filtration grades available

- Multiple filtration grades

- System modularity

- Modular design for scalability

- Operator interface

- Touchscreen interface

- Flavor preservation options

- Maintains natural taste