Continuous filtering centrifuge for solid-liquid separation

Effortlessly separate and filter crystalline or fibrous suspensions with high throughput in compact space, optimizing solid-liquid separation processes for reliable product quality and efficiency in demanding production environments.

Separates and Filters Solid-Liquid Suspensions Continuously

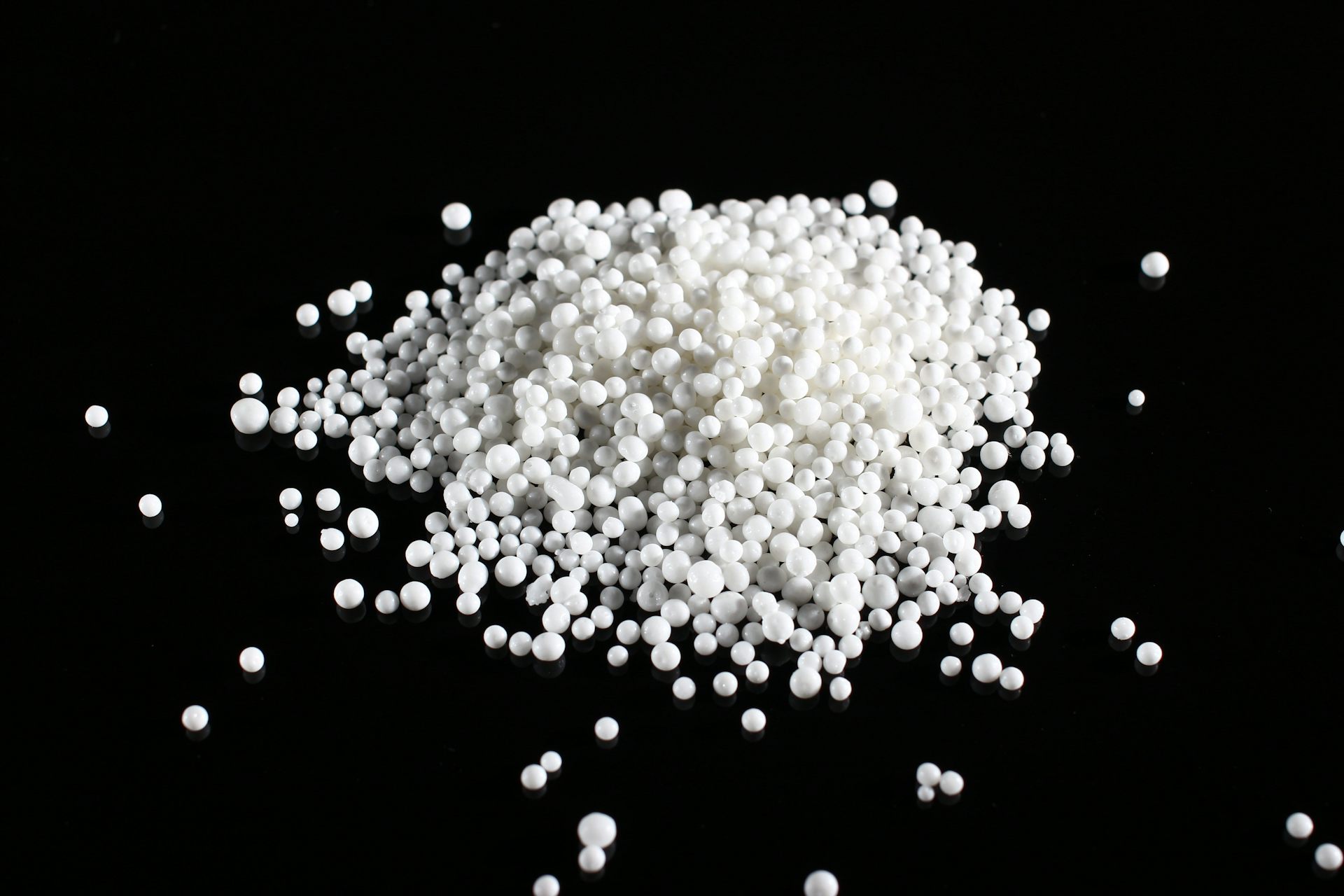

The RINA Serie 500 from Riera Nadeu is a continuous vertical filtering centrifuge designed to optimize the separation process in industries like mining, food, and chemicals. Featuring a conical rotor, it efficiently manages solid-liquid suspensions, accommodating crystalline, granular, and fibrous particles with solid content ranging from 30% to 80%. Its epicycloid gear allows precise control of the residence time by adjusting the feed rate and rotor speed. This series is adept at washing centrifuged solids and separating mother liquors, enhancing the purity of end products such as lithium carbonate, sugar crystals, and cellulose fibers.

With models like the 500F300, 500F400, 500F550, and 500F750 offering throughputs from 1.5 to 35 m³/h, the RINA Serie 500 is suited for high-capacity operations while maintaining a compact and lightweight design. Its ability to operate in ATEX-certified environments makes it suitable for explosive hazardous areas. Additional features include optional lube oil cooling for high-temperature applications and a CIP system for efficient cleaning. The centrifuge is available in multiple configurations to meet specific process requirements, ensuring seamless integration and reliable performance in continuous production lines.

Benefits

- Maximizes production efficiency through high-capacity continuous operation, reducing processing times.

- Compact design allows for easy integration into existing production lines, saving valuable floor space.

- Increases product purity with effective washing and separation capabilities, improving end-product quality.

- Adaptable to explosive hazardous areas with ATEX compliance, ensuring safe operation in challenging environments.

- Enhances process control with adjustable feed rate and rotor speed, enabling precise customization for varying applications.

- Applications

- Chemicals, Lithium mining, Fibrous particles, Crystalline products, Granular particles, Solid-liquid suspensions, Food products

- End products

- Fruit juice concentrates, Cellulose fibers, Ammonium nitrate, Lithium carbonate, Citric acid crystals, Sodium chloride granules, Sugar crystals

- Steps before

- Grinding, Purification, Mixing

- Steps after

- Drying, Packing, Washing

- Input ingredients

- crystallin particles, granular particles, fibrous particles, suspended particles, liquid phase, high filtration rate, solid content 30-80%, particle size 50-5000 µm

- Output ingredients

- filtered solid, centrifuged solid cake, mother liquors, washing liquids, separated liquids

- Market info

- Riera Nadeu is known for its expertise in manufacturing centrifuges and drying equipment, particularly for industrial applications. They are reputed for high-quality, customized, engineered-to-order solutions in separation technologies for various industries.

- Filtration System

- Continuous filtering centrifuge

- Capacity

- 1.5-35 m³/h

- Speed

- Up to 3000 rpm

- G Factor

- Up to 4500 G

- Particle Size

- 50–5000 µm

- Solid Content

- 30-80%

- Power

- 7.5-35 kW

- Dimensions

- 1100x1700x1400 mm to 1800x3000x1800 mm

- Weight

- 1250-5300 kg

- Automation

- Continuous operation mode

- CIP/SIP

- CIP system available

- Cooling System

- Lube oil cooling system available

- Working Mechanism

- Continuous Vertical Filtering with Conical Rotor

- Batch vs Continuous Operation

- Continuous

- Filtration Rate

- 30-80% Solid Content

- Particle Size Range

- 50-5000 µm

- Time Residence Adjustment

- Adjustable Feed Rate and Speed Difference

- Compactness

- High Capacity to Size Ratio

- Operability

- Easy Continuous Operation Mode

- Hazardous Area Adaptation

- Explosive Certification/Approval Available

- Cake Washing Capability

- Yes

- Lube Oil Cooling

- Available for High Temperature Products

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- CIP available

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 50–5000 µm

- Machine footprint

- 1100x1700x1400 mm to 1800x3000x1800 mm

- Basket diameter

- 500 mm

- Discharge method

- Continuous operation

- Weight

- 800 kg to 3500 kg

- Cone shape

- Conical rotor

- Compact footprint

- Yes

- Feed rate adjustment

- Yes, with adjustable speed difference of gear