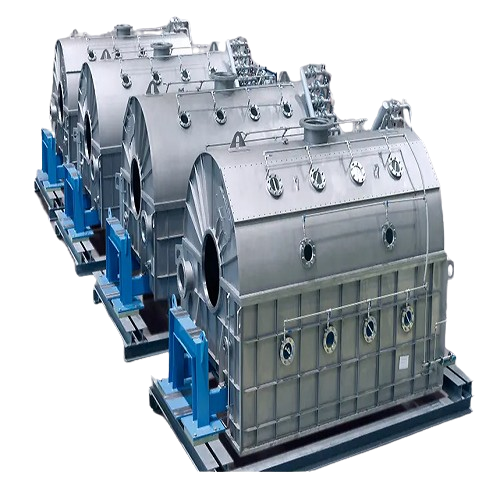

Advanced vacuum and pressure drum filters for high filtration rates

Optimize filtration and separation processes with high-capacity performance and reliable cake washing, perfect for handling continuous operations that demand precision even under pressurized or vacuum conditions.

Filters and Washes Industrial Slurries Efficiently

The Vacuum and Pressure Drum Filters YU and PYU from ANDRITZ offer a robust solution for industrial filtration needs. These filters leverage a single-cell design to deliver exceptional filtration capacity, up to 10 times higher than conventional drum filters, ideal for applications in chemical, pharmaceutical, and food processing industries. Utilizing vacuum and pressure filtration, they efficiently manage tasks such as terephthalic acid purification and winterized salad oil processing, achieving solids throughput of up to 3,500 kg/m² per hour. The equipment supports continuous, high-speed operations, facilitated by its PLC-controlled automation, allowing seamless integration into existing production lines. Engineered for resilience, the YU models are constructed with various stainless steel materials to withstand corrosive environments, while ensuring energy efficiency with optimal motor control. These features, combined with ease of maintenance through a user-friendly design, make the YU and PYU ideal for enhancing operational efficiency and product quality in demanding industrial settings.

Benefits

- Maximizes solids throughput, enhancing production capacity and efficiency.

- Ensures superior product purity with optimized cake washing processes.

- Reduces space requirements in your facility due to compact design.

- Operates efficiently under gas-tight conditions, preserving volatile compounds.

- Minimizes maintenance downtime with robust and durable stainless steel construction.

- Applications

- Chemicals, Specialty chemicals, Industrial filtration, Food processing, Environmental solutions, Pharmaceuticals

- End products

- Polymers, Aspirin, Bisphenol a, Terephthalic acid, Winterized salad oils, Antibiotics, Explosives, Boric acid, Starch, Sodium bicarbonate

- Steps before

- Purification, Emulsification, Grinding

- Steps after

- Sterilization, Packing, Coating

- Input ingredients

- terephthalic acid, bisphenol A, polymers, sodium sulfate, boric acid, explosives, aspirin, antibiotics, medical intermediates, sodium bicarbonate, winterized salad oils, stearates, starch

- Output ingredients

- filtered terephthalic acid, filtered bisphenol A, filtered polymers, filtered sodium sulfate, filtered boric acid, filtered explosives, filtered aspirin, filtered antibiotics, filtered medical intermediates, filtered sodium bicarbonate, filtered winterized salad oils, filtered stearates, filtered starch

- Market info

- ANDRITZ is known for its expertise in supplying industrial ETO equipment and services, specializing in sectors like pulp and paper, hydropower, and metals. It has a strong reputation for innovation and engineering excellence.

- Average particle size

- 50-300 µm

- Filtration capacity

- up to 4, 500 l/m²h

- Solids throughput

- up to 3, 500 kg/m²h

- Operating temperature

- up to 95 °C

- Vacuum area

- up to 93%

- Nominal diameter

- 300-2, 400 mm

- Motor Power

- 0.4-45 kW

- Gas-tight operation

- Possible

- Filter area

- 0.18-35 m²

- Filtration rate

- up to 4, 500 l/m2h

- Solids throughput

- up to 3, 500 kg/m2h

- Operating temperature

- up to 95 °C

- Gas-tight operation

- Possible

- Initial cake formation speed

- Quick

- High washing rates

- Yes

- High vacuum area

- up to 93%

- Rotation speed

- High

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Best suited for

- Free-filtering materials

- Machine footprint

- Compact

- Material

- Stainless steel

- Drum size

- 300 mm to 2, 400 mm diameter

- Filter area

- 0.18 m² to 35 m²

- Control panel type

- PLC

- Motor Power

- 0.4 kW to 45 kW

- Operating weight

- 3, 200 kg to 50, 510 kg

- Material of construction

- Stainless steel

- Integration possibilities

- Gas-tight operation

- Footprint

- Compact design