Hydrogenation reactors for safe and efficient syntheses

Experience safe, on-demand hydrogen generation for precise flow hydrogenation, reducing hazards traditionally associated with handling pressurized gases and pyrophoric materials—perfect for laboratories seeking to enhance synthetic reaction efficiency and safety.

Generates On-Demand Hydrogen for Catalytic Reactions

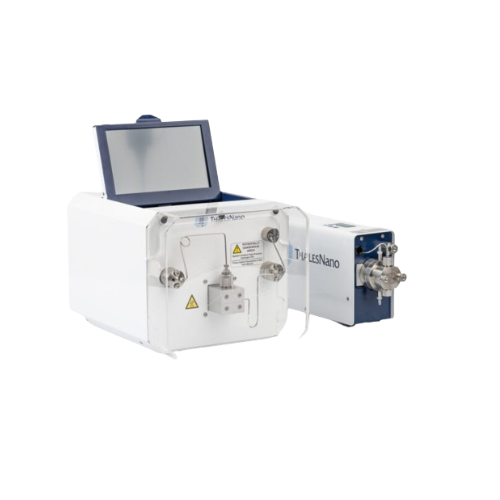

The H-Cube® Mini Plus from ThalesNano offers a unique solution for laboratory-scale continuous flow hydrogenation. This compact system generates hydrogen on-demand through water electrolysis, eliminating the need for stored gas cylinders. It supports a range of catalytic reactions crucial in pharmaceuticals, fine chemicals, and agrochemicals, such as the production of antihypertensive drugs and active pharmaceutical ingredients. With its ability to operate from atmospheric pressure to 100 bar and temperatures up to 100°C, the H-Cube® Mini Plus ensures precise control over reaction conditions. The system’s automation features include an integrated video tutorial, making it user-friendly for research and development departments. Adaptable across liquid, gas, and solid product types, it maintains energy efficiency with its controlled operation. The use of CatCart® cartridges simplifies catalyst handling and enhances safety. Configurable for various scales, it is optimal for both experimental and small-scale production needs.

Benefits

- Enhances safety by eliminating the need for hydrogen gas cylinders.

- Facilitates rapid reaction adjustments, optimizing lab throughput.

- Supports diverse reactions, expanding research capabilities.

- User-friendly interface reduces training time and errors.

- Compact design conserves valuable laboratory space.

- Applications

- Fine chemicals, Fragrances, Agrochemicals, Academia, Flavors, Pharmaceuticals

- End products

- Cholesterol-lowering agents, Fragrance concentrates, Active pharmaceutical ingredients (apis), Research compounds, Antihypertensive drugs, Pesticide precursors, Food flavor enhancers, Insecticide intermediates, Essential oils

- Steps before

- Solvent Preparation, Reactant Solution Preparation, System Parameter Setting

- Steps after

- Product Collection, Post-Reaction Analysis

- Input ingredients

- water, pure solvent, reactants, hydrogen gas, catalyst cartridges (CatCarts®)

- Output ingredients

- reaction product, collection vial

- Market info

- Thalesnano is known for manufacturing advanced flow chemistry solutions, particularly in catalyst and hydrogenation technologies. They are recognized for their expertise in continuous processes, enhancing safety and efficiency in chemical synthesis.

- Temperature range

- From room temperature to 100°C

- Pressure range

- From atmospheric pressure to 100 bar

- Flow rate

- 0.3 – 3 mL/min

- Maximum hydrogen production rate

- 25-30 NmL/min

- Water reservoir capacity

- 100 mL

- Water specifications

- Deionized water with maximum conductivity of 71 nS/cm (min. resistance 14 MΩcm)

- Dimensions

- Width

- Weight

- 7.3 kg

- Voltage

- 100 – 240 V AC

- Typical catalyst amount

- 0.1 – 0.3 g

- Recommended concentration

- 0.01 – 1 M

- Working mechanism

- Hydrogen generation via electrolysis

- Temperature range

- Room temperature to 100°C

- Pressure range

- From atmospheric pressure to 100 bar

- Hydrogen production rate

- 25-30 NmL/min

- Flow rate

- 0.3 – 3 mL/min

- Batch vs. continuous operation

- Continuous

- Automation level

- Automated hydrogen drying system

- Reaction scale

- Milligrams to grams

- CIP/SIP

- Not specified

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Width

- Weight

- 7.3 kg (16.09 lb)

- Discharge method

- Packed column with catalyst stays behind

- Control panel type

- Built-in video tutorial

- Control panel type

- Built-in video tutorial

- Integration possibilities

- Hydrogen mode ON/OFF for different reaction types

- Reaction scale variability

- Milligrams to grams