Fluidized bed dryers/coolers for bulk material processing

Achieve high-efficiency drying and cooling of bulk materials in continuous operations, optimizing your processing line with minimized energy consumption and precise heat control.

Dries and Cools Granular Materials Efficiently

The Fluidized Bed Dryer/Cooler with Heat Exchangers WS-HF-T/K from Allgaier Process Technology is engineered for high-efficiency drying and cooling in chemical, fodder, and foodstuff industries. Featuring a sophisticated fluidized bed design, this equipment integrates tube bundle heat exchangers for consistent heat transfer. It excels in processing salt, soda, potato granules, and more, delivering end-products like baking soda and animal feed pellets with optimal moisture content. Operating continuously, it supports high throughput while minimizing thermal and electrical energy usage. Compatible with various heating media such as saturated steam and thermal oil, the system’s flexibility extends to handling diverse product types, including those with high initial moisture. Its compact size and reduced air requirements enhance integration into existing lines, while its robust design ensures lower process costs and easy maintenance.

Benefits

- Maximizes water evaporation and cooling capacity at low temperatures, increasing process efficiency.

- Reduces energy consumption through optimized heat exchange and minimal hot air use.

- Supports versatile heating media options for adaptability across different production needs.

- Compact design streamlines integration, saving valuable floor space.

- Prevents lump formation, ensuring consistent product quality and reducing maintenance interruptions.

- Applications

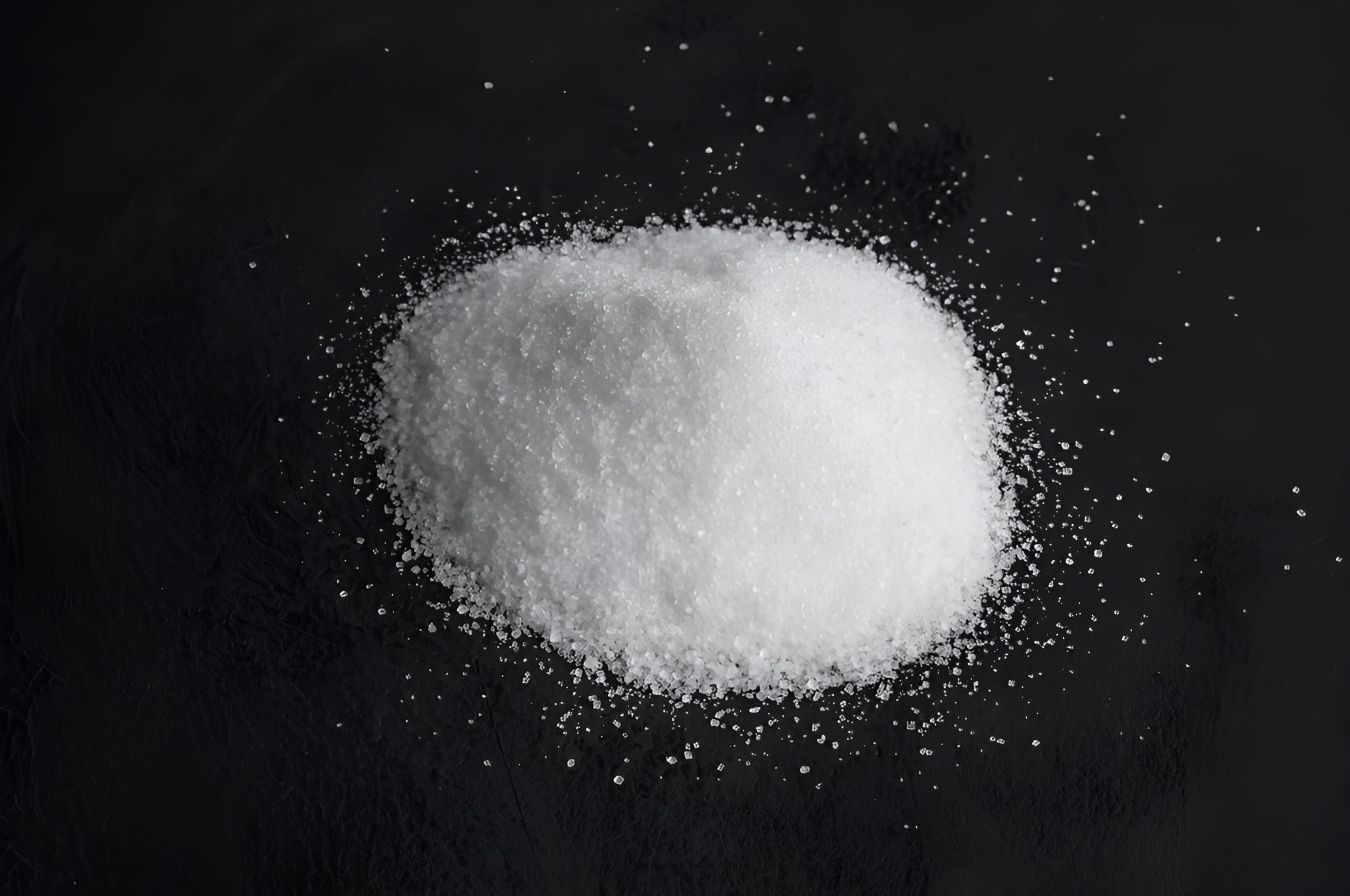

- Soda, Biofuels, Chemical products, Foodstuffs, Potato granules, Fodder, Minerals, Salt

- End products

- Table salt, Dehydrated soup powders, Potato flakes, Mineral nutrients, Baking soda, Animal feed pellets, Soda ash, Burnable pellets

- Steps before

- Purification, Grinding, Moisture Removal, Pre-heating

- Steps after

- Cooling, Packing, Sifting, Granulation

- Input ingredients

- bulk materials, low feed moisture materials, uniform grain size materials, materials with low tendency to form lumps, salt, soda production materials, potato granules

- Output ingredients

- dried materials, cooled materials, processed bulk materials

- Market info

- Allgaier Process Technology is known for manufacturing advanced screening, drying, cooling, and sorting equipment for various industries, specializing in custom-engineered solutions and innovative designs to enhance efficiency and productivity.

- Water Evaporation Capacity

- High

- Air Volume

- Low

- Temperature Required

- Relatively low

- Heating Media

- Saturated steam / Hot water / Thermal oil

- Dryer Size

- Minimum

- Air Equipment Design

- Compact

- Energy Consumption

- Minimized thermal and electrical

- Heat Transfer

- High between heat exchanger tube and fluidized bed

- Feed Moisture Tolerance

- Low

- Grain Size Requirement

- Uniform

- Lump Formation Tendency

- Low

- Working mechanism

- Fluidized bed with tube bundle heat exchangers

- Integrated steps

- Drying and Cooling

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Minimum dryer size

- Discharge method

- Coarse material discharge

- Heating Media Type

- Saturated steam / Hot water / Thermal oil

- Heat Exchanger Type

- Tube bundle

- Compact Design

- Minimum dryer size

- Air Handling Components

- Supply and exhaust air equipment