Acid mist precipitator for sulfuric acid plant gas cleaning

Achieve high-efficiency removal of acid mist and particulates in sulfuric acid plant gas streams with a robust system designed for challenging smelting and refining environments.

Removes Acid Mist and Particulates Efficiently

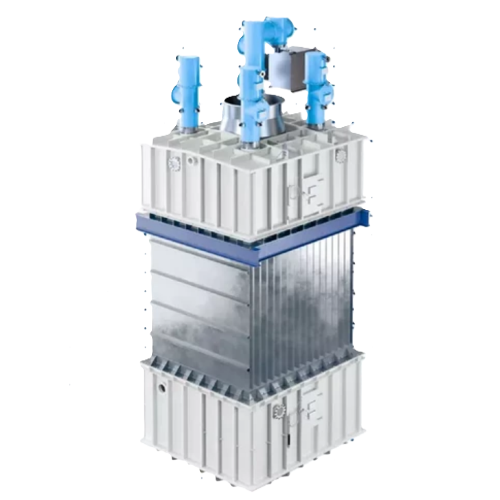

The Part.X PW Acid Mist Wet Electrostatic Precipitator from Dürr Systems is designed for the high-efficiency removal of acid mist and particulates from gas streams, vital for nickel and copper smelters, zinc and lead roasters, and sulfuric acid regeneration. Its robust all-alloy construction ensures durability and low maintenance, featuring seal-welded joints to prevent leaks. The equipment operates by electrically charging contaminants using discharge electrodes on a high-voltage frame, directing them to hexagonal tubular collecting electrodes for effective deposition. The precipitator manages temperature and pressure fluctuations, while positive grounding enhances performance and safety. A built-in washing system maintains collection efficiency and the option for top inlet/outlet configurations allows for seamless integration with existing ductwork. Suitable for continuous operations, the unit optimizes gas cleaning processes, supporting stringent environmental standards. With conventional single-phase or high-performance three-phase transformer/rectifiers, the Part.X PW provides customizable, high-performance solutions in challenging industrial environments.

Benefits

- Achieves up to 99.75% removal efficiency, enhancing air quality and meeting stringent environmental regulations.

- Minimizes maintenance costs with durable all-alloy construction and seal-welded joints that prevent leaks.

- Offers operational flexibility with capability to handle temperature and pressure excursions.

- Integrates seamlessly with existing infrastructure, supporting top inlet/outlet configurations.

- Enhances safety and performance through positive grounding, eliminating the need for conduction path fogging nozzles.

- Applications

- Nickel and copper smelters, High purity acid applications, Sulfuric acid regeneration, Zinc and lead roasters

- End products

- Ultra-pure sulfuric acid, Zinc oxide, Nickel concentrate, Copper cathodes, Lead ingots, Refined sulfuric acid

- Steps before

- Off-gas collection, Gas flow distribution, Contaminant charging

- Steps after

- Gas discharge, Gas washing, Optimal collection efficiency

- Input ingredients

- acid mist, particulate matter, sulfuric acid plant gas, dirty off-gas, solids, aerosols, nickel and copper smelter emissions, zinc and lead roaster emissions

- Output ingredients

- cleaned gas, removal of acid mist, high-purity emissions, reduced pollution

- Market info

- Dürr is known for its expertise in industrial engineering and manufacturing solutions, specializing in automotive painting technology, environmental technology, and production efficiency systems. It has a strong reputation for innovation and quality in engineered-to-order equipment.

- Efficiency

- Single-stage

- Construction Material

- All-alloy

- Pressure Tolerance

- Withstands high-pressure cleaning

- Temperature Excursion Tolerance

- Capable

- Electrode Design

- Rigid mast discharge electrodes

- Collecting Tube Design

- Hexagonal tubular collecting electrodes

- Transformer/Rectifier Type

- Conventional single phase, High-performance three-phase, High-frequency SMPS

- Working mechanism

- Single-stage / Two-stage electrostatic precipitation

- Automation level

- SCADA

- Cleaning method

- Automatic water spray cleaning

- Batch vs. continuous operation

- Continuous

- Gas flow distribution

- Optimized via inlet plenum

- Temperature and pressure tolerance

- High

- Corrosive resistance (e.g. acid mist)

- High

- Material of Construction

- Alloy

- Construction Type

- Seal-welded joints

- Collecting Electrode Shape

- Hexagonal tubular

- Discharge Electrode Type

- Rigid mast

- Frame Design

- Fixed frame

- Inlet/Outlet Configuration

- Bottom and top inlet/outlet options

- Collecting Tube Distribution

- Gas flow distributor

- Control panel type

- PLC / HMI integration

- Discharge method

- Top inlet/outlet configuration

- Collecting electrode design

- Hexagonal tubular

- Discharge electrode design

- Rigid mast with fixed frame

- Transformer/Rectifier options

- Single phase / Three phase / High-frequency SMPS