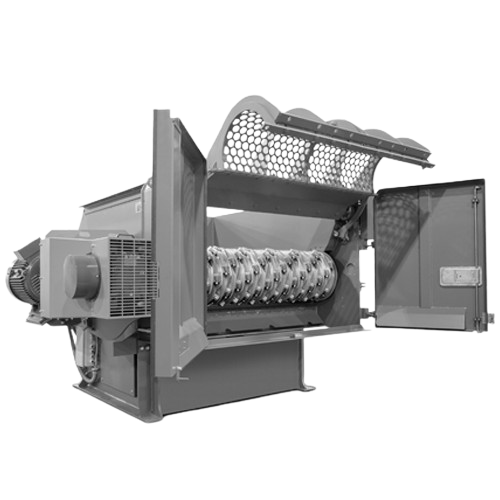

Industrial shredder for recycling and waste management

Efficiently transform challenging waste streams into valuable raw materials while enhancing resource recovery in your production line with this advanced shredding technology, ideal for high-demand applications across diverse waste types.

Efficiently Pre-Breaks and Shreds Diverse Waste Streams

The V Series Shredder Systems from AEC are engineered to provide tailored pre-breaking solutions for demanding waste reduction applications. These systems efficiently process a variety of materials, including plastics, medical waste, and agricultural scrap, by using robust shredding mechanisms designed for high capacity and continuous operation. With integration capabilities suitable for standalone or conveyor-enhanced use, they seamlessly align with granulation and downstream processing needs. Capable of handling bulky scrap and delicate films alike, these shredders contribute to effective recycling by transforming inputs into uniform PET flakes, HDPE pellets, or sterilized waste fragments. The V Series not only supports automated operational settings but also enhances energy efficiency through optimized motor controls, making it a cost-effective option for various industries, from recycling facilities to agricultural waste handlers. Furthermore, customization options ensure that each system meets specific operational requirements, supported by comprehensive engineering consultations to address unique client needs.

Benefits

- Enhances recycling efficiency by transforming diverse waste streams into uniform feedstocks.

- Reduces energy costs through optimized motor control designed for continuous operation.

- Integrates seamlessly in existing production lines, supporting versatile standalone or conveyor setups.

- Minimizes maintenance downtime with robust construction and easy access for servicing.

- Customizable configurations ensure tailored solutions for specific industry requirements.

- Applications

- Post-industrial waste management, Agricultural waste management, Carpet recycling, Plastic recycling, Wood processing, Cardboard processing, Medical waste management, Sheet extrusion products, Post-consumer waste management, Pipe and profile manufacturing

- End products

- Hdpe pellets, Wood chips, Sterilized medical waste fragments, Mulch, Recycled plastic pipes, Agricultural mulch films, Recycled plastic pellets, Pet flakes, Recycled carpet fibers, Cardboard chips, Recycled plastic sheets, Recycled plastic profiles

- Steps before

- Extrusion, Blow Molding, Injection Molding, Baling

- Steps after

- Granulation, Recycling, Sorting, Compacting

- Input ingredients

- Large Purgings, Extrusion, Injection Molding, Blow Molding, Bulky Scrap Plastic, Baled Film, Loose Film, Synthetic Fiber, Recycling - PET, HDPE, PP, Medical Waste, Cardboard, Wood, Carpeting, Hard Plastic, Fabrics, Fibers, Agricultural Scrap, Post-Consumer Scrap, Post-Industrial Scrap, Sheet Extrusion, Pipes and Profiles

- Output ingredients

- Shredded Plastic, Shredded Film, Shredded Fiber, Shredded Waste, Shredded Wood, Processed Materials

- Market info

- AEC (ACS Group) is known for manufacturing industrial equipment such as cooling, heating, and conveying solutions, serving various industries with a reputation for high-quality engineered-to-order systems and reliable customer support.

- Automation

- Stand-alone, Conveyor Integrated, Stacked System

- Application Suitability

- PET, HDPE, PP, Medical Waste, Cardboard, Wood, Carpeting

- Material Type

- Large Purgings, Bulky Scrap Plastic, Baled or Loose Film, Synthetic Fiber

- Processing Technique

- Pre-breaking, Shredding

- Operational Mode

- Demanding Applications

- Working mechanism

- Shredding

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Hard plastics compatibility

- Yes

- Fibers and fabrics compatibility

- Yes

- Post-consumer/post-industrial scrap compatibility

- Yes

- Discharge method

- Convey into granulator / Stacked system

- Control panel type

- Touchscreen / PLC

- Integration possibilities

- Standalone / Integrated with Granulator

- System Configuration

- Stand-alone / Stacked System

- Customization for Material Type

- PET, HDPE, PP, etc.