Synthesis gas waste heat boiler for ammonia plants

Enhance your ammonia production with cutting-edge waste heat recovery that optimizes efficiency by reducing energy loss in the synthesis gas loop, offering you reliable heat exchange and temperature control.

Recovers Heat and Controls Gas Flow

The Synthesis Gas Waste Heat Boiler from BORSIG Process Heat Exchanger GmbH is engineered for high-efficiency heat recovery and gas flow control in ammonia plants. Featuring a patented hot-cold U-tube configuration, it minimizes the risk of hydrogen embrittlement and crevice corrosion, ensuring durability under high-pressure operations up to 350 bar. The boiler is versatile, suitable for both vertical and horizontal installations, and can include integrated components like steam drums and feed water pre-heaters upon customer request. It is ideal for applications in ammonia production, hydrogen generation, and industrial gas recovery, contributing to the manufacture of end-products such as methanol and fertilizers. Designed for continuous high-temperature operation, it prioritizes safety and efficiency, with austenitic materials lining the gas chambers for optimal thermal management. The unit integrates seamlessly into existing production lines, bolstering energy recovery and emission control, while offering customization options for specific operational needs.

Benefits

- Enhances energy recovery efficiency, reducing operational costs.

- Minimizes maintenance with low-risk hydrogen embrittlement design.

- Supports high-pressure operations, increasing process reliability.

- Offers flexibility in installation and integration, adapting to plant specifications.

- Boosts product yield through optimized heat exchange and gas control.

- Applications

- Industrial gas recovery, Ammonia production, Hydrogen production, Heat exchange applications, Energy recovery, Synthesis gas processing, Emission control

- End products

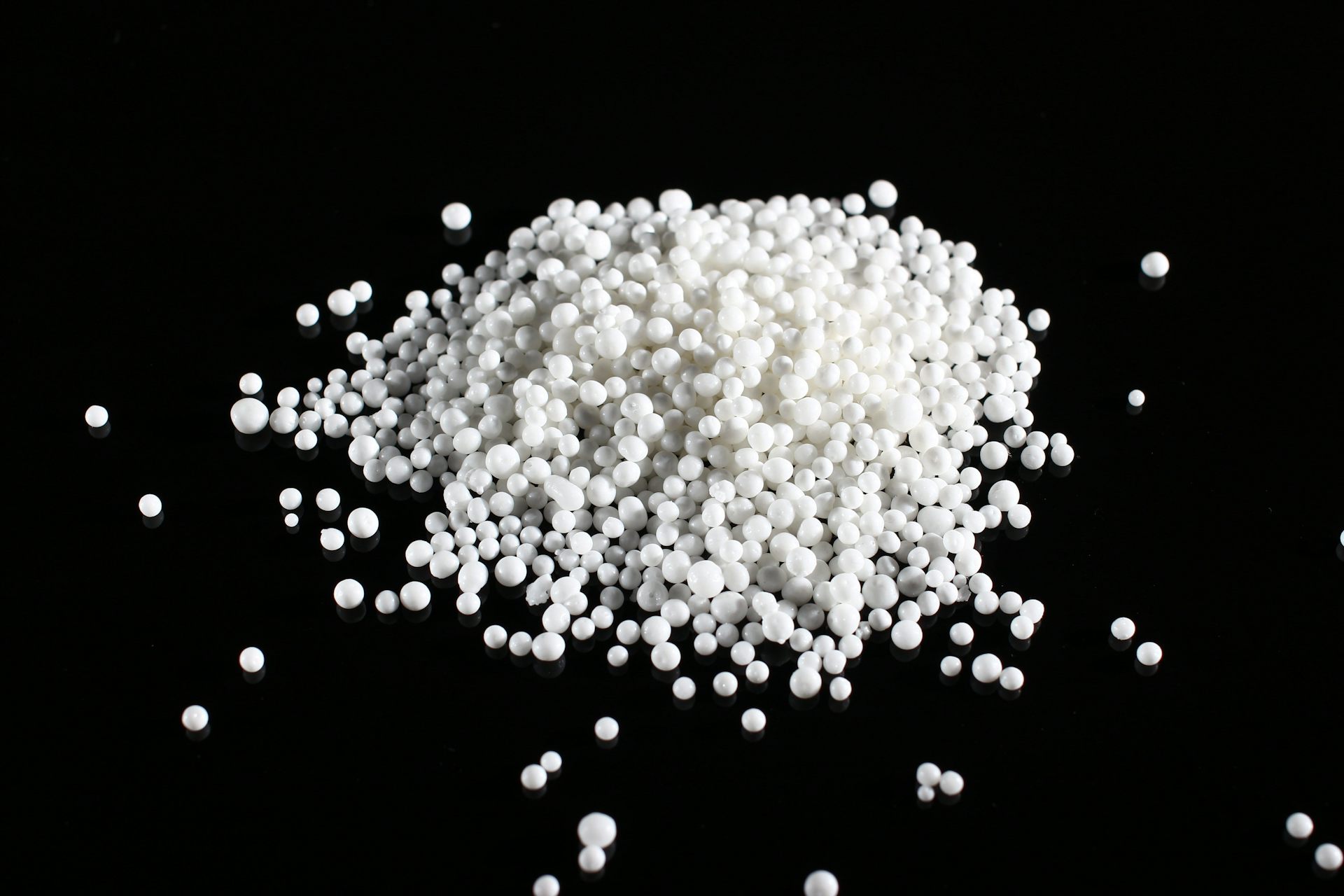

- Liquid fertilizers, Synthesis gas components, Methanol, Ammonia, Ammonium nitrate, Hydrogen gas, Urea, Hydrogen fuel, Fertilizers

- Steps before

- Synthesis Gas Production, Feedstock Preparation, Gas Reforming

- Steps after

- Ammonia Synthesis, Cooling, Ammonia Separation, Product Storage

- Input ingredients

- synthesis gas, hot gas

- Output ingredients

- steam, cooled gas

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Gas Pressure

- Up to 350 bar (35, 000 kPa)

- Steam Pressure

- Up to 160 bar (16, 000 kPa)

- Design Configuration

- Vertical or Horizontal

- Tube Arrangement

- Quadratic pitch with hot-cold tube arrangement

- Nitriding Temperature

- Below 380°C

- Internal Material

- Austenitic material

- Crevice Corrosion Prevention

- Hydraulically expanded tube ends

- Gas Outlet Temperature Control

- Bypass installation available

- Mounting Position

- Vertical / Horizontal

- Integration Type

- Steam Drum Integration

- Bypass Control

- Gas Inlet/Outlet Temperature Control

- Tube Arrangement

- Quadratic Pitch

- Temperature Control

- Below 380°C

- Hydraulic Expansion

- Tube Sheet Thickness

- Embrittlement Protection

- Hydrogen Embrittlement Prevention

- Corrosive resistance (e.g. acids)

- Austenitic material

- Temperature resistance

- Below nitriding temperature of 380°C

- Hydrogen embrittlement resistance

- Hydraulically expanded tube ends

- Cleanability

- Clean gas flow around internals

- Thermal stress resistance

- Hot-cold tube arrangement

- Mounting Position

- Vertical / Horizontal

- Tube Arrangement

- Quadratic Pitch

- Feed Water Pre-heater

- Optional Integration

- Steam Drum Integration

- Optional

- Bypass Installation

- Optional

- Installation orientation

- Vertical / Horizontal

- Steam drum integration

- Optional

- Feed water pre-heater

- Optional

- Bypass installation

- Optional