High-pressure preheaters for power plants

Optimize your power plant’s efficiency by efficiently preheating feedwater, reducing fuel consumption, and alleviating boiler pressure with state-of-the-art high-pressure preheaters designed for seamless integration into your operation.

Preheats and Efficiently Transfers Heat

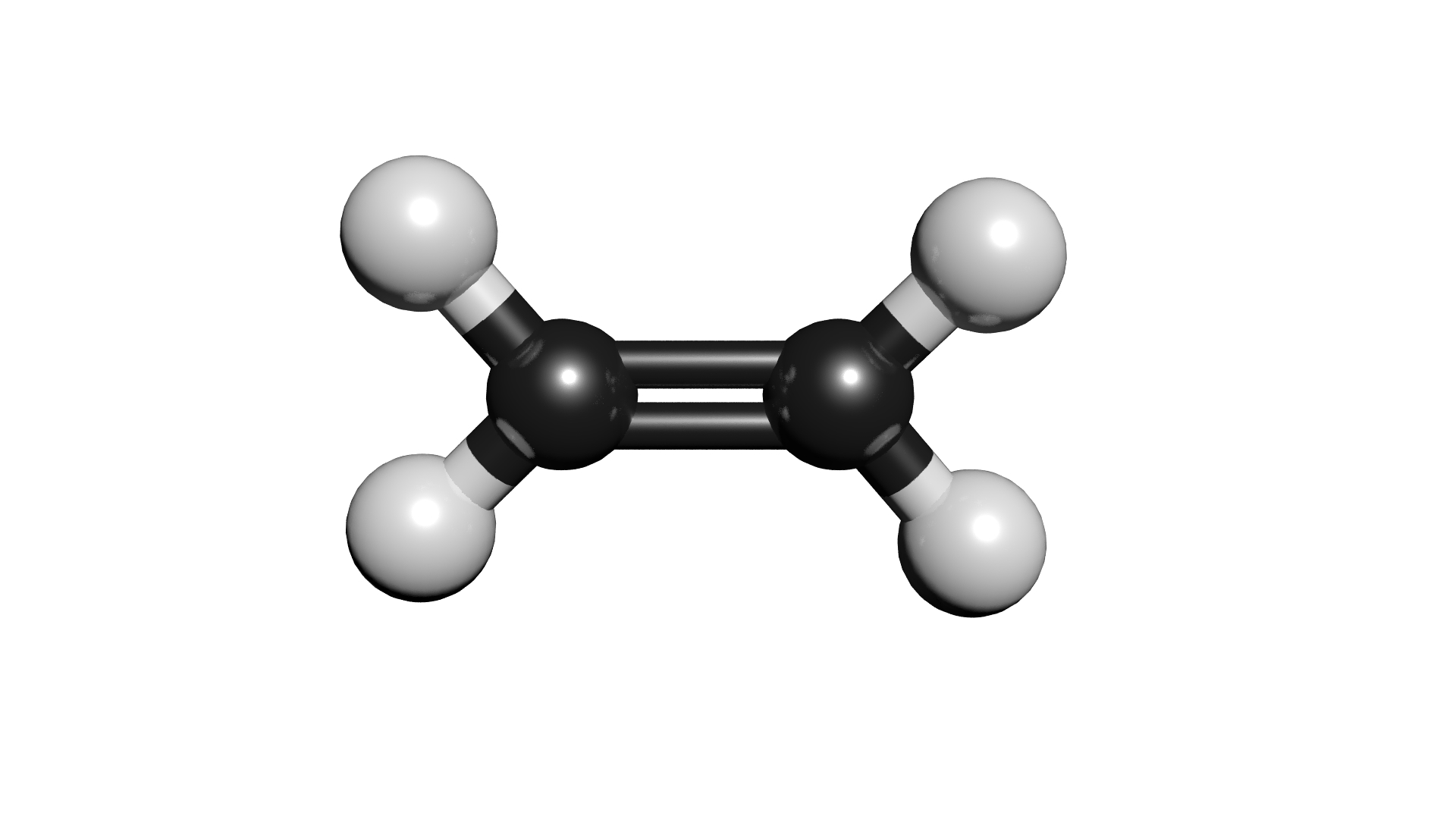

The HP and LP Preheaters and Special Vessels from BORSIG Process Heat Exchanger GmbH offer a high-precision solution for chemical and power plant applications. Utilizing superheated steam extraction and efficient heat transfer, these preheaters increase the feed water temperature, optimizing the steam cycle and reducing boiler energy demands. This system is ideal for processing feed water in high-pressure zones before entering boilers, significantly enhancing thermal efficiency across operations. Ideal for applications in oil refineries, petrochemical, and chemical industries, this equipment supports the production of key end-products like gasoline, ethylene, and vinyl chloride. Built to handle continuous, high-speed operations, these preheaters are offered with material options that ensure corrosion resistance for long-lasting performance. Integration into existing systems is seamless, with customizable solutions tailored to specific process conditions.

Benefits

- Enhances system efficiency by lowering boiler energy demands, reducing fuel consumption.

- Supports high-speed, continuous operations, ensuring maximum throughput.

- Customizable material options offer durability and resistance to chemical-induced corrosion.

- Seamless integration with existing systems minimizes installation and operational disruptions.

- Optimizes thermal performance, contributing to overall cost savings and process sustainability.

- Applications

- Petrochemical, Power plants, Chemical industries, Oil refinery

- End products

- Propylene, Vinyl chloride, Methanol, Polyethylene, Ammonia, Diesel fuel, Styrene, Polypropylene, Electricity, Ethylene, Synthetic rubber, Gasoline, Jet fuel, Fertilizers, Lubricating oils

- Steps before

- Purification, Water treatment, Feedwater pumping

- Steps after

- Condensation, Feedwater heating, Steam generation

- Input ingredients

- feedwater, superheated steam, condensate

- Output ingredients

- preheated feedwater, condensed steam, extracted heat

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Preheating Capacity

- High-pressure area

- Automation

- Special installations for heat transfer

- Location

- Between boiler feed pump and evaporator inlet

- Material

- Special materials according to process conditions

- Compliance

- DGRL AD 2000 and API standards

- Condensate Section

- Superheated steam condenses

- Heat Exchanger Type

- Tube bundle

- Efficiency

- Fuel saving by preheating

- Design

- Tailored solutions for process specifications

- Working mechanism

- Preheating feedwater using superheated steam

- Integrated steps

- Condensate heat recovery and feedwater preheating

- Flow type

- Inline Continuous

- Energy efficiency

- Improved by reducing fuel usage

- Automation level

- Manual / PLC

- Suitable Industry

- Oil Refinery, Petrochemical, Chemical, Power Plants

- API compliance

- API 617, API 618, API 11P, API 672

- Machine footprint

- Customizable

- Shape

- Cylindrical / Tubular

- Size

- Customized according to specifications

- Discharge method

- Condensate acceleration installations

- Construction materials

- Special materials as per requirement

- Material selection

- Special materials for customized solutions

- Integration with existing systems

- Custom integration with boiler feed systems

- Control system options

- Customized control solutions

- Design layout

- Custom design based on process requirements