Bulk powder transfer safety device

Ensure stable and secure docking by minimizing equipment damage during powder transfer processes with an innovative shock absorption solution, designed to handle misalignment efficiently.

Absorbs Docking Forces and Accommodates Misalignment

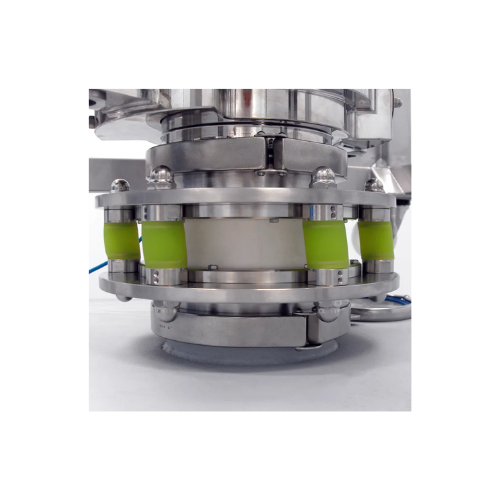

The Compensator from ChargePoint Technology is a robust solution designed to enhance the docking processes in powder handling systems. This device excels by absorbing the forces generated during the docking of active and passive units, reducing wear and potential damage. Ideal for pharmaceutical, chemical, and battery industries, it ensures precise alignment, even under challenging conditions. Integrating seamlessly with existing systems, it connects directly to active units or via Tri-Clamp connections, accommodating valve sizes from DN100 (4”) to DN300 (12”). Constructed with 316L stainless steel and EPDM, the Compensator offers exceptional durability and compatibility with a wide range of materials. This is crucial for operations involving sensitive products like APIs, sterile powders, and battery components. By facilitating shock absorption and misalignment accommodation, this device contributes significantly to operational efficiency and equipment lifespan, making it an invaluable addition to any processing line.

Benefits

- Enhances equipment lifespan by absorbing docking forces, reducing mechanical stress.

- Ensures precise alignment, minimizing risk of misalignment-related downtime.

- Provides flexibility in connection with direct or Tri-Clamp options.

- Constructed with 316L stainless steel for corrosion resistance in chemical applications.

- Supports seamless integration with existing powder handling systems for improved operational efficiency.

- Applications

- Fine chemicals, Biopharmaceuticals, Powder containment, Batteries, Pharmaceuticals

- End products

- Insulin, Lithium-ion battery components, Monoclonal antibodies, Polymer powders, Coatings, Active pharmaceutical ingredients (apis), Sterile powders, Conductive additives, Specialized fine chemicals, Industrial chemicals, Electrolyte powders, Injectable drugs, Tablets, Capsules

- Steps before

- Steps after

- Input ingredients

- bulk powder, materials for docking processes

- Output ingredients

- contained product in EPDM sleeve, processed bulk powder

- Market info

- Chargepoint Technology is known for its expertise in designing and manufacturing high containment and sterile transfer solutions for pharmaceutical and biopharmaceutical industries, particularly in powder containment and aseptic transfer systems.

- Size

- DN100 (4”) to DN300 (12”)

- Product contact materials

- 316L and EPDM

- Connection to Active

- Direct to Active or Tri-Clamp

- Connection to process

- Tri-Clamp

- Docking force absorption

- Shock absorption device

- Misalignment accommodation

- Specifically designed for misalignment

- Docking safety and repeatability

- Ensures safe and repeatable docking

- Direct process integration

- Couples directly between active unit and process machine

- Compatible with mechanical handling

- Compatible with equipment like column hoists

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- FDA Materials

- 316L and EPDM

- Size (Valve size compatibility)

- DN100 (4”) to DN300 (12”)

- Product contact materials

- 316L and EPDM

- Connection to Active

- Direct to Active or Tri-Clamp

- Connection to Process

- Tri-Clamp

- Central Sleeve Material

- EPDM

- Spring System

- Series of springs

- Connection to Active

- Direct to Active or Tri-Clamp

- Connection to Process

- Tri-Clamp

- Valve Size Compatibility

- DN100 (4”) to DN300 (12”)